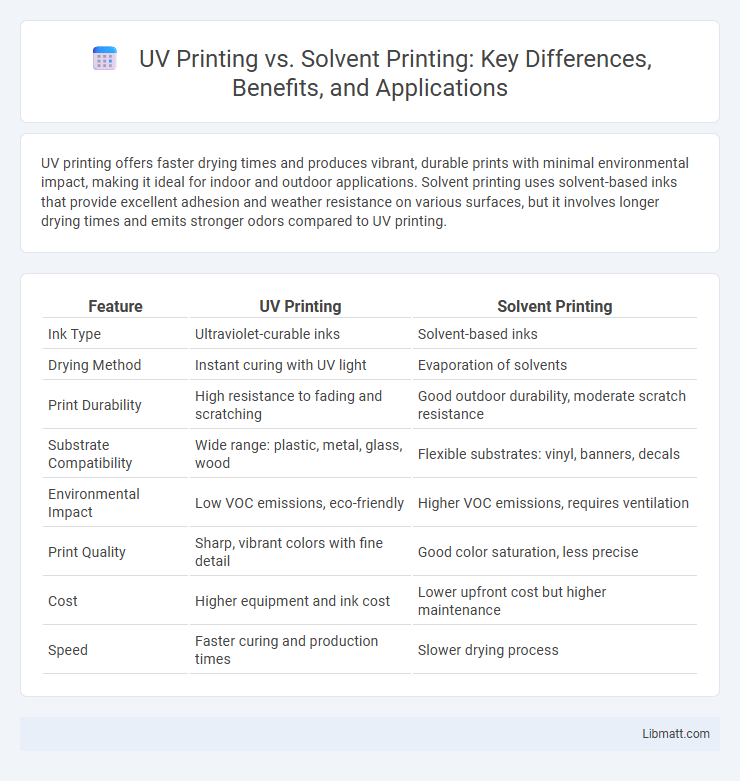

UV printing offers faster drying times and produces vibrant, durable prints with minimal environmental impact, making it ideal for indoor and outdoor applications. Solvent printing uses solvent-based inks that provide excellent adhesion and weather resistance on various surfaces, but it involves longer drying times and emits stronger odors compared to UV printing.

Table of Comparison

| Feature | UV Printing | Solvent Printing |

|---|---|---|

| Ink Type | Ultraviolet-curable inks | Solvent-based inks |

| Drying Method | Instant curing with UV light | Evaporation of solvents |

| Print Durability | High resistance to fading and scratching | Good outdoor durability, moderate scratch resistance |

| Substrate Compatibility | Wide range: plastic, metal, glass, wood | Flexible substrates: vinyl, banners, decals |

| Environmental Impact | Low VOC emissions, eco-friendly | Higher VOC emissions, requires ventilation |

| Print Quality | Sharp, vibrant colors with fine detail | Good color saturation, less precise |

| Cost | Higher equipment and ink cost | Lower upfront cost but higher maintenance |

| Speed | Faster curing and production times | Slower drying process |

Introduction to UV and Solvent Printing

UV printing uses ultraviolet light to instantly cure ink on various surfaces, producing vibrant, durable prints ideal for detailed graphics and short production runs. Solvent printing relies on solvent-based inks that dissolve materials for strong adhesion, making it suitable for outdoor signage and long-lasting applications. Your choice depends on desired print quality, substrate compatibility, and environmental considerations.

How UV Printing Works

UV printing uses ultraviolet light to instantly cure or dry the ink as it is printed onto a variety of surfaces, creating vibrant and durable images. The process involves specialized UV inks containing photosensitive components that harden upon exposure to UV light, allowing for high-resolution printing on materials like plastic, glass, metal, and wood. This technology enables ink to bond directly to the substrate without the need for lengthy drying times, making it ideal for fast production and environmentally friendly applications.

How Solvent Printing Works

Solvent printing works by using solvent-based inks that dissolve the surface of the printing substrate, allowing the ink to penetrate and adhere permanently. This process is ideal for outdoor applications because it produces durable, water-resistant, and UV-resistant prints. Your choice of solvent printing ensures long-lasting visuals on materials like vinyl, banners, and adhesive films.

Key Differences Between UV and Solvent Printing

UV printing uses ultraviolet light to instantly cure ink, resulting in vibrant colors and a durable finish on various materials, while solvent printing relies on solvent-based inks that penetrate surfaces for high durability and water resistance. UV printing produces less odor and is more environmentally friendly compared to solvent printing, which emits strong fumes requiring ventilation. Your choice depends on the needed application, surface compatibility, and environmental considerations, with UV printing suited for detailed, short-run projects and solvent printing favored for outdoor signage and long-lasting prints.

Print Quality and Color Vibrancy Comparison

UV printing delivers superior print quality with sharp details and vibrant colors due to its quick curing process that prevents ink from spreading. Solvent printing offers strong color vibrancy and durability on various substrates but may produce slightly less precise images because of ink absorption and drying time. Your choice between UV and solvent printing should consider the importance of crisp detail versus color intensity on specific materials.

Durability and Longevity of Prints

UV printing offers superior durability and longevity due to its ability to cure ink instantly using ultraviolet light, resulting in prints that resist fading, scratching, and environmental damage over time. Solvent printing produces durable prints as well, especially outdoors, since solvent inks penetrate the substrate deeply, making them resistant to water and UV exposure, though they may degrade faster than UV prints under harsh conditions. Choosing UV printing for your projects ensures longer-lasting, vibrant results with minimal wear, ideal for applications demanding high resilience.

Material Compatibility and Versatility

UV printing offers superior material compatibility, allowing direct printing on a wide range of substrates including plastics, glass, metal, and wood, due to its quick curing process under ultraviolet light. Solvent printing is versatile for outdoor applications, effectively adhering to vinyl, banners, and flexible materials with durable, weather-resistant inks. Both technologies enable high-quality prints, but UV printing provides greater adaptability for rigid and sensitive materials without requiring extensive surface preparation.

Environmental Impact and Safety

UV printing uses ultraviolet light to cure inks, producing fewer volatile organic compounds (VOCs) and hazardous emissions compared to solvent printing, which relies on chemical solvents with higher VOC content. Solvent printing poses greater risks to workers' health due to inhalation of toxic fumes, while UV printing offers a safer workplace environment with lower exposure to harmful substances. Environmentally, UV printing generates less hazardous waste and reduces air pollution, making it a more sustainable choice for eco-conscious printing operations.

Cost Considerations: UV vs Solvent Printing

UV printing generally incurs higher upfront equipment costs but offers lower long-term expenses due to faster curing times and reduced material waste. Solvent printing requires less initial investment but involves ongoing costs for solvent-based inks and ventilation systems, increasing operational expenses. Your choice depends on balancing initial capital with ongoing maintenance and environmental considerations for cost efficiency.

Choosing the Right Printing Method for Your Project

UV printing offers superior color accuracy and quick drying times, making it ideal for detailed graphics on non-porous materials like acrylic and metal. Solvent printing excels in outdoor applications due to its strong adhesive properties and resistance to weather, suitable for vinyl banners and vehicle wraps. Selecting between these methods depends on project requirements such as substrate type, durability, and environmental exposure to ensure optimal print quality and longevity.

UV printing vs solvent printing Infographic

libmatt.com

libmatt.com