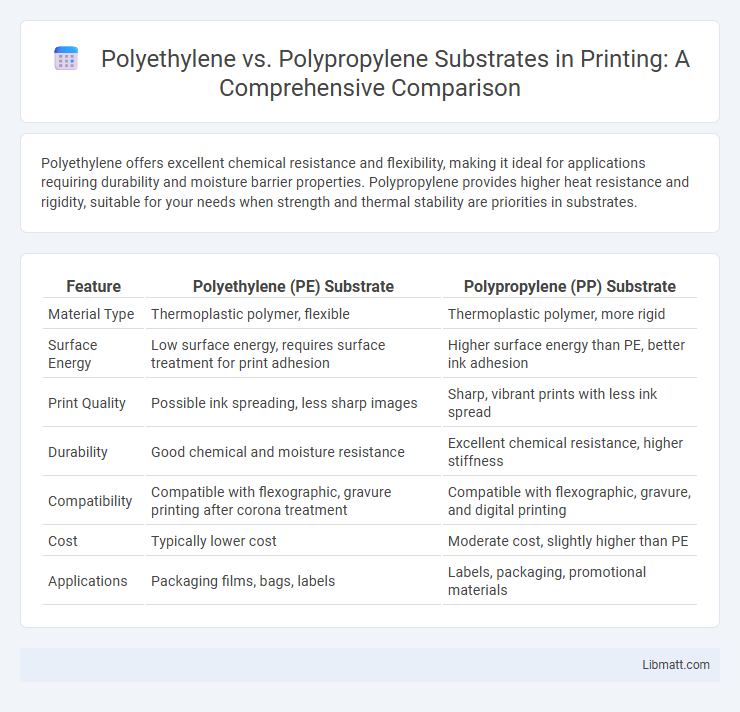

Polyethylene offers excellent chemical resistance and flexibility, making it ideal for applications requiring durability and moisture barrier properties. Polypropylene provides higher heat resistance and rigidity, suitable for your needs when strength and thermal stability are priorities in substrates.

Table of Comparison

| Feature | Polyethylene (PE) Substrate | Polypropylene (PP) Substrate |

|---|---|---|

| Material Type | Thermoplastic polymer, flexible | Thermoplastic polymer, more rigid |

| Surface Energy | Low surface energy, requires surface treatment for print adhesion | Higher surface energy than PE, better ink adhesion |

| Print Quality | Possible ink spreading, less sharp images | Sharp, vibrant prints with less ink spread |

| Durability | Good chemical and moisture resistance | Excellent chemical resistance, higher stiffness |

| Compatibility | Compatible with flexographic, gravure printing after corona treatment | Compatible with flexographic, gravure, and digital printing |

| Cost | Typically lower cost | Moderate cost, slightly higher than PE |

| Applications | Packaging films, bags, labels | Labels, packaging, promotional materials |

Introduction to Polyethylene and Polypropylene Substrates

Polyethylene and polypropylene substrates are widely used thermoplastic materials distinguished by their chemical structure and performance characteristics. Polyethylene, known for its flexibility and chemical resistance, is commonly utilized in packaging, containers, and films, while polypropylene offers higher rigidity, thermal resistance, and is favored in automotive parts, textiles, and labeling applications. Both substrates provide cost-effective solutions with varied mechanical properties suitable for diverse industrial uses.

Chemical Structure and Composition

Polyethylene (PE) consists of repeating ethylene monomers with a simple linear or branched hydrocarbon chain, making it highly flexible and chemically resistant. Polypropylene (PP) features a methyl group attached to every other carbon in its polymer backbone, resulting in increased rigidity and higher melting points compared to PE. Understanding the distinct chemical structures of these substrates can help you select the ideal material for applications requiring specific thermal and mechanical properties.

Physical Properties Comparison

Polyethylene substrate offers high flexibility, excellent impact resistance, and superior moisture barrier properties, making it ideal for applications requiring durability and flexibility. Polypropylene substrate provides higher stiffness, better chemical resistance, and greater tensile strength, which suits it for applications demanding structural stability and resistance to aggressive substances. The choice between polyethylene and polypropylene substrates depends on balancing flexibility and toughness with rigidity and chemical resistance needs.

Mechanical Performance Differences

Polyethylene exhibits superior flexibility and impact resistance compared to polypropylene, which offers higher tensile strength and rigidity. Polypropylene's mechanical properties make it better suited for applications requiring dimensional stability and resistance to fatigue, while polyethylene excels in environments demanding toughness and elongation. These differences in mechanical performance influence their selection for substrates in packaging, automotive parts, and consumer goods.

Durability and Environmental Resistance

Polypropylene substrate offers higher durability and better resistance to chemicals, moisture, and UV exposure compared to polyethylene, making it ideal for applications requiring long-lasting performance. Polyethylene, while cost-effective and flexible, tends to degrade faster under harsh environmental conditions and prolonged sunlight exposure. Understanding these differences helps you select the substrate that best balances durability and environmental resistance for your project.

Printability and Surface Characteristics

Polyethylene substrates exhibit low surface energy, making print adhesion challenging without surface treatment such as corona or plasma treatment to improve ink receptivity. Polypropylene offers slightly higher surface energy and better inherent printability, resulting in crisper, more vibrant print output with fewer pre-treatment requirements. Your choice between these materials should consider the necessity for ink durability and print clarity in applications like packaging and labeling.

Applications in Various Industries

Polyethylene substrates are widely used in packaging, agriculture, and automotive industries due to their flexibility, chemical resistance, and moisture barrier properties. Polypropylene substrates offer superior tensile strength and thermal resistance, making them ideal for medical, food packaging, and textiles applications. Both materials serve critical roles in manufacturing labels, films, and containers across diverse industrial sectors.

Cost Analysis and Economic Considerations

Polyethylene substrates generally offer lower raw material costs compared to polypropylene, making them more budget-friendly for large-scale applications. Your choice between polyethylene and polypropylene should weigh not only initial expenses but also long-term economic factors such as durability, chemical resistance, and recyclability. Polypropylene's higher resistance to heat and chemicals can reduce maintenance and replacement costs, potentially offsetting its higher upfront price over time.

Sustainability and Recycling Aspects

Polyethylene and polypropylene substrates differ significantly in sustainability and recycling aspects, with polyethylene being more widely recycled due to its simpler polymer structure and higher demand in recycling streams. Polypropylene offers better resistance to chemical and heat degradation, which can complicate recycling but extends product life, reducing overall waste. Your choice between these substrates should consider local recycling capabilities and the environmental impact of material lifecycle to optimize sustainability.

Choosing the Right Substrate: Key Factors

Selecting the right substrate between polyethylene and polypropylene depends on factors like chemical resistance, flexibility, and application environment. Polyethylene offers superior impact resistance and is ideal for thick, durable packaging, while polypropylene excels in rigidity and high-temperature tolerance, making it suitable for food containers and automotive parts. Assessing factors such as environmental stress, exposure to chemicals, and required mechanical properties ensures optimal substrate choice for specific industrial or consumer needs.

Polyethylene vs Polypropylene Substrate Infographic

libmatt.com

libmatt.com