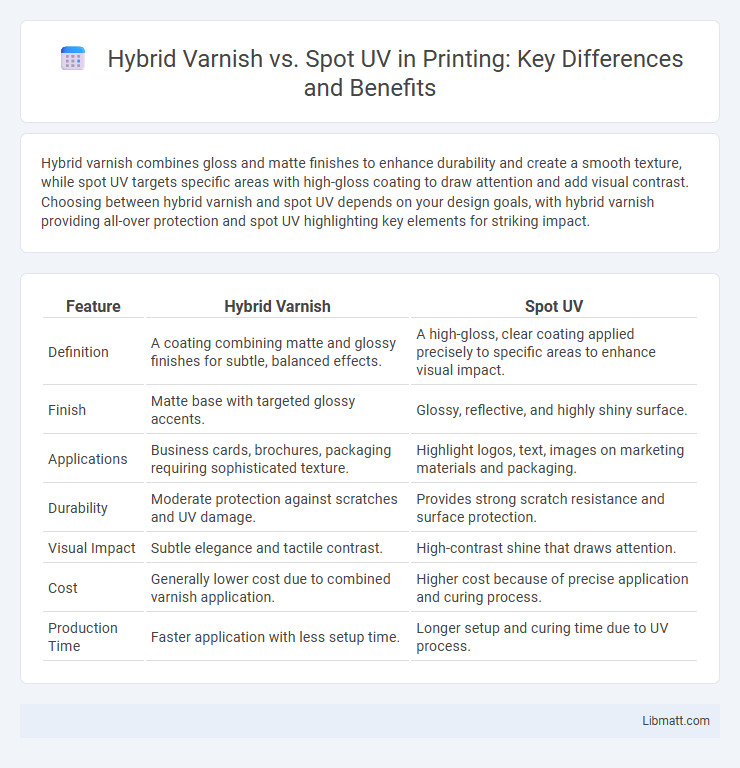

Hybrid varnish combines gloss and matte finishes to enhance durability and create a smooth texture, while spot UV targets specific areas with high-gloss coating to draw attention and add visual contrast. Choosing between hybrid varnish and spot UV depends on your design goals, with hybrid varnish providing all-over protection and spot UV highlighting key elements for striking impact.

Table of Comparison

| Feature | Hybrid Varnish | Spot UV |

|---|---|---|

| Definition | A coating combining matte and glossy finishes for subtle, balanced effects. | A high-gloss, clear coating applied precisely to specific areas to enhance visual impact. |

| Finish | Matte base with targeted glossy accents. | Glossy, reflective, and highly shiny surface. |

| Applications | Business cards, brochures, packaging requiring sophisticated texture. | Highlight logos, text, images on marketing materials and packaging. |

| Durability | Moderate protection against scratches and UV damage. | Provides strong scratch resistance and surface protection. |

| Visual Impact | Subtle elegance and tactile contrast. | High-contrast shine that draws attention. |

| Cost | Generally lower cost due to combined varnish application. | Higher cost because of precise application and curing process. |

| Production Time | Faster application with less setup time. | Longer setup and curing time due to UV process. |

Understanding Hybrid Varnish and Spot UV

Hybrid varnish combines matte and gloss finishes, creating a flexible coating that enhances print durability and visual appeal across various surfaces. Spot UV applies a high-gloss, raised coating selectively to specific areas, emphasizing design elements with striking contrast and texture. Understanding these differences helps you choose the best option for highlighting key visuals and protecting your printed materials.

How Hybrid Varnish Works

Hybrid Varnish combines the durability of UV coating with the smooth finish of aqueous coatings by curing a blend of UV and water-based varnishes using ultraviolet light. This innovative process creates a protective layer that enhances print quality and resistance while maintaining eco-friendly properties. Your printed materials benefit from a subtle, uniform sheen that offers both aesthetic appeal and long-lasting protection.

The Spot UV Process Explained

The Spot UV process involves applying a high-gloss ultraviolet coating selectively to specific areas of a printed piece to create a striking contrast with the uncoated surfaces. This technique enhances textures and visual appeal by targeting logos, images, or text with precision, resulting in a highly polished and professional finish. Compared to hybrid varnish, which combines matte and gloss finishes over larger areas, Spot UV is ideal for emphasizing details without covering the entire surface.

Key Differences Between Hybrid Varnish and Spot UV

Hybrid varnish combines the benefits of both aqueous and UV coatings, providing a more durable and flexible finish that enhances print durability and resistance to scuffing. Spot UV applies a high-gloss, reflective coating selectively on specific areas, creating a striking contrast and texture but with less coverage than hybrid varnish. Your choice depends on whether you want uniform protection with subtle shine or dramatic, localized gloss effects.

Advantages of Hybrid Varnish Coating

Hybrid varnish coating offers superior durability and enhanced scratch resistance compared to spot UV, making it ideal for high-traffic printed materials. It provides a uniform, matte or glossy finish that protects against fingerprints and smudges while maintaining vibrant color clarity. Hybrid varnish also allows for faster drying times and cost-effective large-scale application, improving production efficiency without compromising quality.

Benefits of Using Spot UV Effects

Spot UV effects enhance printed materials by adding a glossy, eye-catching finish to specific areas, creating contrast and depth that draws attention to your key design elements. This technique improves durability by protecting targeted sections from wear and tear, making your print projects more resistant to scratches and smudges. Spot UV offers greater design flexibility compared to hybrid varnish, allowing for intricate patterns and precise application that elevate the overall visual impact of your marketing materials.

Design Impact: Hybrid Varnish vs Spot UV

Hybrid varnish delivers a subtle, all-over matte or satin finish that enhances colors while providing a smooth texture, making it ideal for designs seeking uniform elegance. Spot UV offers high-gloss, targeted highlights that create striking contrasts and draw attention to specific design elements or text. Choosing between hybrid varnish and spot UV depends on the desired visual impact: hybrid varnish supports cohesive aesthetics, whereas spot UV emphasizes focal points with reflective shine.

Cost Considerations for Each Method

Hybrid varnish typically offers a more cost-effective solution for large print runs due to its simpler application process and lower material expenses, making it ideal for budget-conscious projects. Spot UV involves higher costs because of specialized equipment and precise application requirements, which increase production time and overall expenses. Choosing between hybrid varnish and spot UV often depends on balancing budget constraints with desired visual impact and print volume.

Best Applications for Hybrid Varnish and Spot UV

Hybrid varnish excels in providing smooth, durable coatings ideal for full-surface coverage on packaging, book covers, and business cards, enhancing both tactile feel and visual appeal. Spot UV is best suited for highlighting specific design elements such as logos, images, or text, creating a striking contrast with a glossy, reflective finish on invitations, brochures, and premium marketing materials. Businesses prioritize hybrid varnish for overall protection and subtle enhancement while choosing Spot UV to draw attention to key features and add dimensional impact.

Choosing the Right Finish for Your Print Project

Hybrid varnish combines the protective qualities of varnish with the glossy appeal of UV coating, offering durability and a subtle shine ideal for brochures and magazines. Spot UV selectively applies a high-gloss coating to specific areas, enhancing visual contrast and tactile experience on business cards and invitations. Selecting between hybrid varnish and spot UV depends on the desired aesthetic effect and functional requirements of your print project.

hybrid varnish vs spot UV Infographic

libmatt.com

libmatt.com