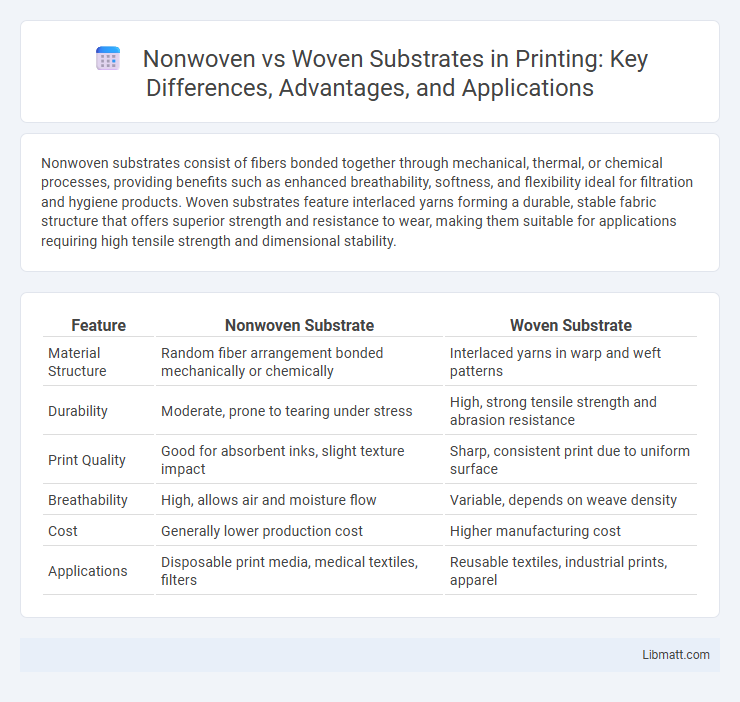

Nonwoven substrates consist of fibers bonded together through mechanical, thermal, or chemical processes, providing benefits such as enhanced breathability, softness, and flexibility ideal for filtration and hygiene products. Woven substrates feature interlaced yarns forming a durable, stable fabric structure that offers superior strength and resistance to wear, making them suitable for applications requiring high tensile strength and dimensional stability.

Table of Comparison

| Feature | Nonwoven Substrate | Woven Substrate |

|---|---|---|

| Material Structure | Random fiber arrangement bonded mechanically or chemically | Interlaced yarns in warp and weft patterns |

| Durability | Moderate, prone to tearing under stress | High, strong tensile strength and abrasion resistance |

| Print Quality | Good for absorbent inks, slight texture impact | Sharp, consistent print due to uniform surface |

| Breathability | High, allows air and moisture flow | Variable, depends on weave density |

| Cost | Generally lower production cost | Higher manufacturing cost |

| Applications | Disposable print media, medical textiles, filters | Reusable textiles, industrial prints, apparel |

Introduction to Nonwoven and Woven Substrates

Nonwoven substrates consist of fibers bonded together by chemical, mechanical, heat, or solvent treatment, offering high porosity and flexibility ideal for filtration and medical applications. In contrast, woven substrates are created by interlacing yarns in a structured grid pattern, providing superior strength, durability, and dimensional stability used extensively in textiles and industrial fabrics. Understanding the fundamental differences in fiber arrangement and bonding methods highlights their distinct performance characteristics and suitability across various industries.

Material Composition and Manufacturing Processes

Nonwoven substrates are composed of fibers bonded together through mechanical, thermal, or chemical processes without weaving, often using synthetic fibers like polypropylene or polyester for enhanced filtration and durability. Woven substrates consist of interlaced yarns arranged in perpendicular patterns, typically made from natural or synthetic fibers such as cotton or nylon, providing strength and flexibility through traditional weaving techniques. Understanding your application requirements helps determine whether the controlled fiber arrangement of woven substrates or the randomized, layered structure of nonwoven substrates offers better performance.

Key Physical Differences Between Nonwoven and Woven Substrates

Nonwoven substrates consist of fibers bonded together by chemical, mechanical, or heat processes, resulting in a fabric that is porous and flexible with random fiber orientation, whereas woven substrates are created by interlacing yarns at right angles, providing a structured and durable fabric with uniform strength. Nonwoven materials typically exhibit higher absorbency and softness, while woven substrates offer greater tensile strength and dimensional stability. Your choice between these substrates depends on the application requirements for flexibility, strength, and moisture management.

Performance Characteristics: Strength, Durability, and Flexibility

Nonwoven substrates exhibit enhanced flexibility and moderate strength, making them ideal for applications requiring lightweight and conformable materials. Woven substrates demonstrate superior durability and tensile strength due to their interlaced fiber structure, providing robust resistance to wear and tear. The choice between nonwoven and woven substrates depends on the balance needed between flexibility and long-term mechanical performance in specific industrial or consumer applications.

Absorbency and Breathability Comparison

Nonwoven substrates generally exhibit higher absorbency due to their random fiber arrangement, which creates more void spaces for liquid retention compared to woven substrates with tightly interlaced fibers. Breathability in woven substrates typically surpasses that of nonwovens because the structured weave allows greater air permeability and moisture vapor transmission. The choice between nonwoven and woven substrates depends on specific application needs, balancing absorbency requirements with ventilation performance.

Application Areas: Where Each Substrate Excels

Nonwoven substrates excel in applications requiring high filtration efficiency, disposable hygiene products, medical gowns, and insulation materials due to their random fiber arrangement and superior fluid resistance. Woven substrates are ideal for durable goods, apparel, upholstery, and industrial applications where strength, flexibility, and breathability are essential. Your choice depends on the specific performance needs, with nonwoven materials favoring single-use or specialized filtration, while woven fabrics support long-term, heavy-duty use.

Cost-Effectiveness and Production Efficiency

Nonwoven substrates offer superior cost-effectiveness due to lower raw material usage and faster production speeds compared to woven substrates, which require more labor-intensive weaving processes. Production efficiency is enhanced in nonwovens by streamlined manufacturing techniques such as spunbond or meltblown, enabling high-volume output with minimal downtime. Your choice between the two should consider nonwoven materials' ability to reduce expenses while maintaining speed in large-scale applications.

Sustainability and Environmental Impact

Nonwoven substrates typically offer enhanced sustainability through lower water and energy consumption in their production compared to woven substrates, which require extensive weaving processes. Your choice of nonwoven materials can reduce environmental impact by enabling faster biodegradation and easier recyclability due to their simpler fiber bonding. Woven substrates, while durable, often involve chemical treatments and longer manufacturing cycles, increasing their overall ecological footprint.

Quality Control and Testing Standards

Nonwoven substrates undergo rigorous quality control processes emphasizing fiber uniformity, porosity, and tensile strength to ensure consistent performance in filtration and medical applications. Woven substrates are tested for thread count, weave pattern integrity, and abrasion resistance, adhering to standards like ASTM D3775 and ISO 13934 for durability and reliability. Both substrates require specialized testing methods such as air permeability, tensile strength, and microbial barrier assessments to meet industry-specific regulatory requirements.

Choosing the Right Substrate for Your Application

Nonwoven substrates offer superior filtration, breathability, and cost-effectiveness, making them ideal for disposable medical supplies and hygiene products. Woven substrates provide enhanced durability, strength, and abrasion resistance, preferred in heavy-duty apparel and industrial applications. Selecting the right substrate depends on specific requirements such as tensile strength, permeability, and end-use environment to ensure optimal performance and longevity.

Nonwoven Substrate vs Woven Substrate Infographic

libmatt.com

libmatt.com