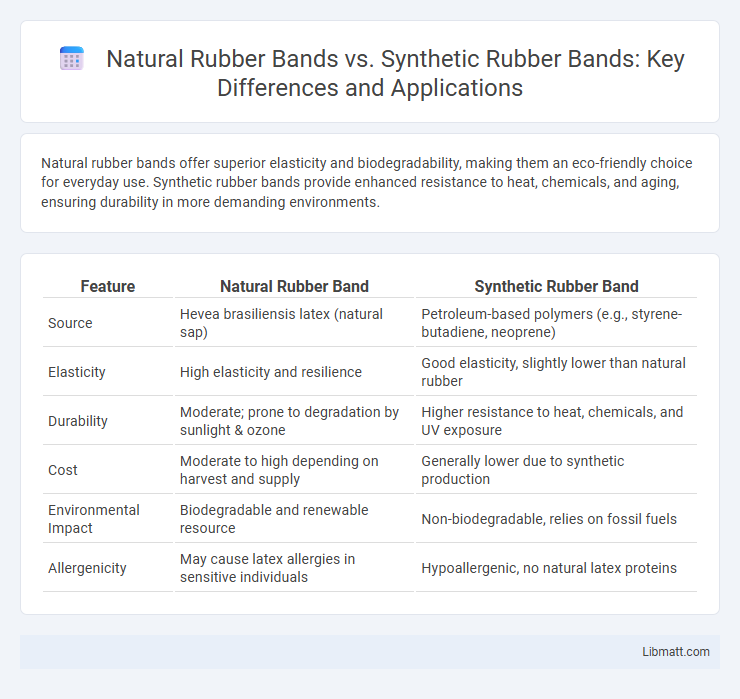

Natural rubber bands offer superior elasticity and biodegradability, making them an eco-friendly choice for everyday use. Synthetic rubber bands provide enhanced resistance to heat, chemicals, and aging, ensuring durability in more demanding environments.

Table of Comparison

| Feature | Natural Rubber Band | Synthetic Rubber Band |

|---|---|---|

| Source | Hevea brasiliensis latex (natural sap) | Petroleum-based polymers (e.g., styrene-butadiene, neoprene) |

| Elasticity | High elasticity and resilience | Good elasticity, slightly lower than natural rubber |

| Durability | Moderate; prone to degradation by sunlight & ozone | Higher resistance to heat, chemicals, and UV exposure |

| Cost | Moderate to high depending on harvest and supply | Generally lower due to synthetic production |

| Environmental Impact | Biodegradable and renewable resource | Non-biodegradable, relies on fossil fuels |

| Allergenicity | May cause latex allergies in sensitive individuals | Hypoallergenic, no natural latex proteins |

Introduction to Rubber Bands: Natural vs Synthetic

Natural rubber bands are made from latex derived from rubber trees (Hevea brasiliensis), offering superior elasticity and biodegradability compared to synthetic rubber bands. Synthetic rubber bands are produced using petroleum-based polymers such as styrene-butadiene rubber (SBR) or neoprene, providing enhanced durability and resistance to heat, chemicals, and environmental factors. The choice between natural and synthetic rubber bands depends on application requirements, balancing flexibility, lifespan, and environmental impact.

Composition and Manufacturing Processes

Natural rubber bands are made from latex extracted from the Hevea brasiliensis tree, undergoing processes like coagulation, drying, and vulcanization to enhance elasticity and strength. Synthetic rubber bands, typically composed of polymers like styrene-butadiene or neoprene, are produced through chemical polymerization and curing methods, offering greater resistance to temperature and chemicals. The manufacturing of natural rubber emphasizes sustainable harvesting and natural polymer treatments, whereas synthetic rubber relies on petrochemical derivatives and controlled industrial synthesis.

Physical Properties Comparison

Natural rubber bands exhibit superior elasticity and tensile strength due to their polymer structure, allowing greater stretchability and resilience under stress. Synthetic rubber bands, often made from materials like silicone or neoprene, offer enhanced resistance to heat, oils, and environmental degradation, improving durability in harsh conditions. Both types differ significantly in hardness and elasticity retention, with natural rubber excelling in flexibility and synthetic variants favored for chemical and temperature stability.

Environmental Impact and Sustainability

Natural rubber bands are derived from sustainable rubber trees, making them biodegradable and less harmful to the environment compared to synthetic rubber bands, which are petroleum-based and contribute to plastic pollution. The production of synthetic rubber involves significant energy consumption and greenhouse gas emissions, whereas natural rubber supports carbon sequestration through rubber plantations. Choosing natural rubber bands aligns with your commitment to reducing environmental impact and promoting sustainable materials.

Cost Analysis and Market Availability

Natural rubber bands generally incur higher production costs due to the labor-intensive harvesting of latex from rubber trees, resulting in a higher market price compared to synthetic rubber bands. Synthetic rubber bands are often more affordable and widely available because they are mass-produced using petroleum-based materials, ensuring consistent quality and scalability. Your choice between natural and synthetic rubber bands should consider budget constraints and availability in your specific market or application needs.

Performance and Durability

Natural rubber bands offer superior elasticity and tensile strength, making them highly flexible and ideal for tasks requiring repeated stretching. Synthetic rubber bands, often made from materials like neoprene or silicone, provide enhanced resistance to heat, chemicals, and UV exposure, resulting in longer-lasting durability in harsh environments. While natural rubber excels in natural grip and stretch, synthetic variants surpass in maintaining performance stability under extreme conditions.

Safety and Allergen Concerns

Natural rubber bands contain latex proteins that can trigger allergic reactions in sensitive individuals, making them a safety concern for those with latex allergies. Synthetic rubber bands, made from materials like neoprene or silicone, offer hypoallergenic alternatives that reduce the risk of skin irritation and allergic responses. Choosing synthetic rubber bands can protect your health by minimizing exposure to potential allergens commonly found in natural latex products.

Common Uses and Applications

Natural rubber bands are often preferred in applications requiring high elasticity and biodegradability, such as in agricultural uses, food packaging, and medical supplies. Synthetic rubber bands, made from materials like neoprene or silicone, offer enhanced resistance to heat, chemicals, and UV exposure, making them ideal for industrial, automotive, and outdoor applications. You can select the best rubber band based on the specific durability and environmental conditions of your use case.

Consumer Preferences and Industry Trends

Consumer preferences for natural rubber bands often highlight eco-friendliness and biodegradability, making them a top choice for environmentally conscious buyers. Industry trends show a rising demand for synthetic rubber bands due to their enhanced durability, resistance to heat, and versatility in industrial applications. Your selection depends on whether sustainability or performance under specific conditions is the priority.

Conclusion: Choosing the Right Rubber Band

Natural rubber bands offer superior elasticity and biodegradability, making them ideal for eco-conscious applications and short-term use. Synthetic rubber bands provide enhanced durability and resistance to chemicals, heat, and aging, suited for industrial or heavy-duty purposes. Selecting the right rubber band depends on balancing environmental impact, required strength, and specific usage conditions.

Natural Rubber Band vs Synthetic Rubber Band Infographic

libmatt.com

libmatt.com