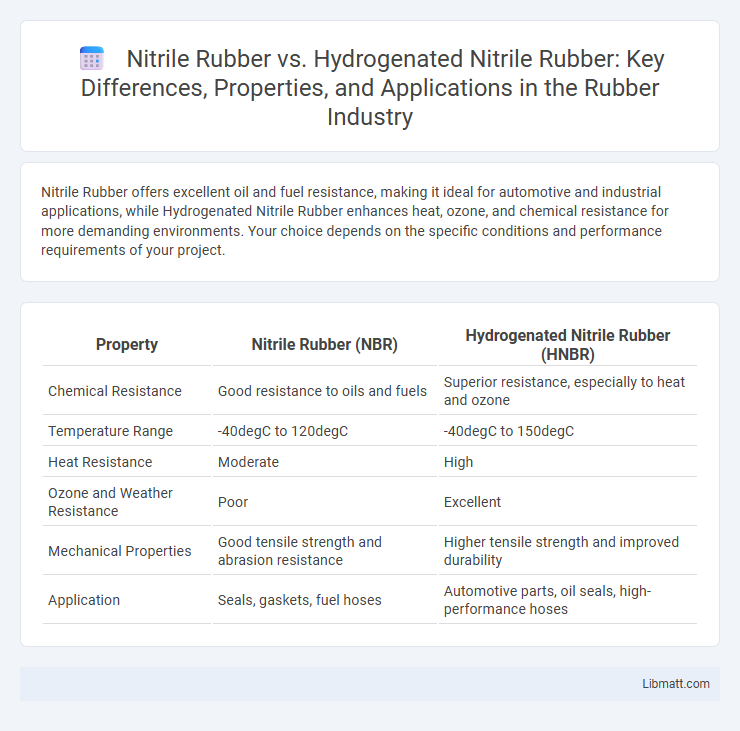

Nitrile Rubber offers excellent oil and fuel resistance, making it ideal for automotive and industrial applications, while Hydrogenated Nitrile Rubber enhances heat, ozone, and chemical resistance for more demanding environments. Your choice depends on the specific conditions and performance requirements of your project.

Table of Comparison

| Property | Nitrile Rubber (NBR) | Hydrogenated Nitrile Rubber (HNBR) |

|---|---|---|

| Chemical Resistance | Good resistance to oils and fuels | Superior resistance, especially to heat and ozone |

| Temperature Range | -40degC to 120degC | -40degC to 150degC |

| Heat Resistance | Moderate | High |

| Ozone and Weather Resistance | Poor | Excellent |

| Mechanical Properties | Good tensile strength and abrasion resistance | Higher tensile strength and improved durability |

| Application | Seals, gaskets, fuel hoses | Automotive parts, oil seals, high-performance hoses |

Introduction to Nitrile Rubber and Hydrogenated Nitrile Rubber

Nitrile Rubber (NBR) is a synthetic polymer known for its excellent resistance to oils, fuels, and chemicals, commonly used in automotive and industrial applications. Hydrogenated Nitrile Rubber (HNBR) is a modified version of NBR with enhanced heat, ozone, and chemical resistance due to hydrogenation, improving durability in extreme environments. Your choice between NBR and HNBR depends on the specific requirements for temperature resistance and chemical exposure in your application.

Chemical Structure Differences

Nitrile Rubber (NBR) consists of acrylonitrile and butadiene copolymers with unsaturated carbon-carbon bonds, which contribute to its resistance against oils and fuels but limit its stability against heat and ozone. Hydrogenated Nitrile Rubber (HNBR) undergoes selective hydrogenation that saturates the polymer backbone, enhancing its chemical stability, heat resistance, and mechanical strength. This hydrogenation process removes the double bonds in HNBR, distinguishing its chemical structure from NBR and improving its performance in demanding industrial applications.

Key Physical Properties Comparison

Nitrile Rubber (NBR) exhibits excellent resistance to oils and fuels, with tensile strength ranging from 10 to 25 MPa and elongation at break between 300% and 600%. Hydrogenated Nitrile Rubber (HNBR), enhanced through saturation of the polymer backbone, offers superior heat resistance up to 150degC and improved resistance to ozone, chemicals, and mechanical wear, with tensile strength typically from 20 to 30 MPa and elongation around 250%-450%. Both materials provide robust sealing performance but HNBR is preferred in high-temperature and chemically aggressive environments due to its enhanced physical durability.

Temperature Resistance Capabilities

Nitrile rubber offers effective temperature resistance up to approximately 120degC, making it suitable for general-purpose applications involving moderate heat exposure. Hydrogenated nitrile rubber (HNBR) significantly enhances temperature resistance, maintaining its properties in environments reaching 150degC to 160degC, which is ideal for demanding automotive and industrial seals. Your choice between nitrile and HNBR should consider the maximum operating temperatures to ensure reliable performance and longevity under thermal stress.

Oil and Chemical Resistance Analysis

Nitrile rubber (NBR) offers excellent resistance to oils, fuels, and petroleum-based chemicals, making it ideal for applications involving mineral oils and aliphatic hydrocarbons. Hydrogenated nitrile rubber (HNBR) enhances this resistance further, providing superior chemical stability against aromatic hydrocarbons, heat aging, and ozone exposure, which significantly extends its service life in aggressive industrial environments. Your choice between these materials should focus on the specific chemical exposure conditions, as HNBR delivers better performance in higher temperatures and more corrosive chemical settings.

Applications in Various Industries

Nitrile Rubber (NBR) is widely used in automotive fuel systems, sealing, and oil-resistant gloves due to its excellent resistance to petroleum-based fluids. Hydrogenated Nitrile Rubber (HNBR) offers superior thermal and ozone resistance, making it ideal for aerospace, industrial hoses, and high-performance seals in harsh environments. Both materials serve crucial roles in manufacturing, with HNBR preferred for applications requiring enhanced durability and NBR favored for cost-effective, oil-resistant solutions.

Advantages and Limitations

Nitrile rubber offers excellent resistance to petroleum-based fuels and oils, making it ideal for automotive and industrial applications, but it has limited resistance to ozone and weathering. Hydrogenated nitrile rubber enhances these properties with improved heat, ozone, and chemical resistance, providing superior performance in harsh environments. However, hydrogenated nitrile rubber is generally more expensive and may have slightly lower flexibility compared to standard nitrile rubber.

Cost and Availability

Nitrile Rubber (NBR) is generally more cost-effective and widely available due to its extensive use in various industries such as automotive and oil. Hydrogenated Nitrile Rubber (HNBR) has a higher price point reflecting its enhanced heat, chemical, and ozone resistance, making it less common but preferred for specialized applications. Supply chains for NBR are well-established globally, whereas HNBR availability may be limited depending on regional manufacturers and demand for high-performance elastomers.

Environmental and Regulatory Considerations

Nitrile rubber (NBR) is widely used but faces increasing regulatory scrutiny due to its lower resistance to ozone and UV degradation compared to hydrogenated nitrile rubber (HNBR), which offers enhanced environmental durability. HNBR's improved stability reduces the need for frequent replacements, aligning better with sustainability goals and stricter environmental regulations on material lifespan and waste. Your choice between NBR and HNBR should factor in compliance with environmental standards and the long-term impacts of rubber degradation.

Choosing the Right Material for Your Needs

Nitrile Rubber (NBR) offers excellent resistance to oils, fuels, and chemicals, making it ideal for automotive and industrial applications requiring durability and flexibility. Hydrogenated Nitrile Rubber (HNBR) provides enhanced thermal stability, ozone resistance, and mechanical strength, suitable for high-temperature environments and demanding conditions. Choosing the right material depends on your specific requirements for temperature range, chemical exposure, and mechanical performance.

Nitrile Rubber vs Hydrogenated Nitrile Rubber Infographic

libmatt.com

libmatt.com