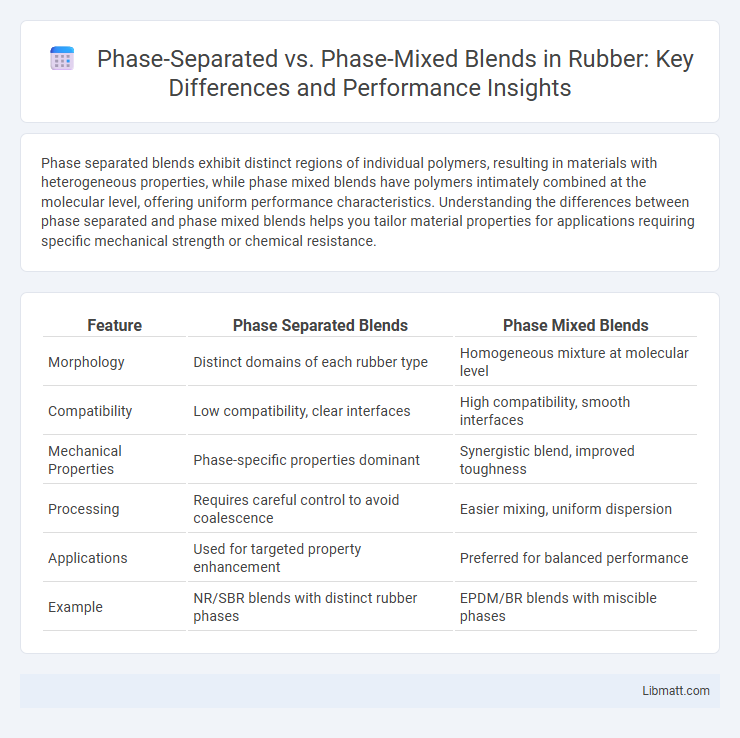

Phase separated blends exhibit distinct regions of individual polymers, resulting in materials with heterogeneous properties, while phase mixed blends have polymers intimately combined at the molecular level, offering uniform performance characteristics. Understanding the differences between phase separated and phase mixed blends helps you tailor material properties for applications requiring specific mechanical strength or chemical resistance.

Table of Comparison

| Feature | Phase Separated Blends | Phase Mixed Blends |

|---|---|---|

| Morphology | Distinct domains of each rubber type | Homogeneous mixture at molecular level |

| Compatibility | Low compatibility, clear interfaces | High compatibility, smooth interfaces |

| Mechanical Properties | Phase-specific properties dominant | Synergistic blend, improved toughness |

| Processing | Requires careful control to avoid coalescence | Easier mixing, uniform dispersion |

| Applications | Used for targeted property enhancement | Preferred for balanced performance |

| Example | NR/SBR blends with distinct rubber phases | EPDM/BR blends with miscible phases |

Introduction to Polymer Blends: Phase Separated vs Phase Mixed

Polymer blends exhibit distinct microstructures characterized as phase separated or phase mixed, influencing their physical properties and applications. Phase separated blends display discrete domains of individual polymers due to immiscibility, resulting in heterogeneous morphology and often enhanced mechanical strength or barrier performance. Phase mixed blends demonstrate molecular-level compatibility, forming homogeneous materials with improved optical clarity and ductility, critical for applications requiring uniformity and flexibility.

Defining Phase Separation in Polymer Systems

Phase separation in polymer systems occurs when incompatible polymers within a blend spontaneously segregate into distinct domains, resulting in a heterogeneous morphology. This phenomenon directly influences the blend's mechanical, thermal, and barrier properties by creating well-defined interfaces between phases. Understanding phase separation enables you to tailor material properties by controlling domain size, distribution, and interfacial adhesion in phase-separated versus phase-mixed blends.

Characteristics of Phase Mixed Blends

Phase mixed blends exhibit a homogeneous morphology where polymer components are intimately mixed at the molecular level, resulting in uniform physical and mechanical properties. These blends often demonstrate enhanced transparency, consistent tensile strength, and improved impact resistance due to the absence of distinct phase boundaries. Your application benefits from the improved compatibility and reduced phase separation, which enhances overall blend performance and durability.

Key Factors Influencing Phase Behavior in Blends

Key factors influencing phase behavior in polymer blends include molecular compatibility, interaction parameters (such as Flory-Huggins interaction parameter kh), and processing conditions like temperature and shear rate. The degree of miscibility is governed by the thermodynamic driving forces and molecular size disparity, which determine whether the blend is phase separated or phase mixed. Morphology control is achieved by tuning blend composition, molecular weight distribution, and thermal history to optimize performance properties.

Morphological Differences Between Phase Separated and Mixed Blends

Phase separated blends exhibit distinct, discrete domains where components segregate due to incompatibility, leading to sharp interfaces and heterogenous morphology. In contrast, phase mixed blends display a more homogeneous structure with molecular-level mixing and absence of distinct phase boundaries. Understanding these morphological differences is crucial for tailoring the mechanical and thermal properties in your polymer blend applications.

Effects on Mechanical and Thermal Properties

Phase separated blends exhibit distinct domains that enhance mechanical strength and thermal stability by limiting chain mobility and improving load transfer. Phase mixed blends often show increased flexibility and impact resistance due to improved polymer compatibility and homogenous morphology. Your choice between these blends affects the balance of toughness, heat resistance, and processing performance tailored to specific application demands.

Techniques to Analyze Blend Morphology

Techniques to analyze blend morphology include scanning electron microscopy (SEM) and transmission electron microscopy (TEM), which provide high-resolution images to distinguish phase-separated from phase-mixed structures. Differential scanning calorimetry (DSC) reveals thermal transitions that indicate the degree of miscibility between polymer phases. X-ray diffraction (XRD) and atomic force microscopy (AFM) offer additional insights into crystalline structures and surface topography, helping you optimize blend performance.

Applications of Phase Separated Polymer Blends

Phase separated polymer blends exhibit distinct phases that enhance properties such as impact resistance, thermal stability, and chemical resistance, making them ideal for automotive parts, packaging materials, and electronic components. Their phase morphology allows for tailored mechanical and barrier properties critical in applications requiring durability and performance under stress. You can leverage these specialized blends to achieve a combination of properties unattainable with single polymers or fully miscible blends.

Applications of Phase Mixed Polymer Blends

Phase mixed polymer blends exhibit enhanced mechanical and thermal properties, making them ideal for automotive parts, packaging materials, and flexible electronics. Their uniform morphology improves transparency and impact resistance, which is essential for consumer goods like optical lenses and protective coatings. Your choice of phase mixed blends can lead to better performance in high-demand applications requiring durability and clarity.

Future Trends in Polymer Blend Engineering

Phase separated blends exhibit distinct polymer domains improving mechanical strength and thermal stability, while phase mixed blends offer enhanced homogeneity and optical clarity. Future trends in polymer blend engineering focus on tunable interfacial compatibilizers and advanced processing techniques like reactive extrusion to achieve precise control over blend morphology. Your ability to optimize phase behavior will drive innovations in sustainable materials and multifunctional polymer composites.

Phase separated vs Phase mixed blends Infographic

libmatt.com

libmatt.com