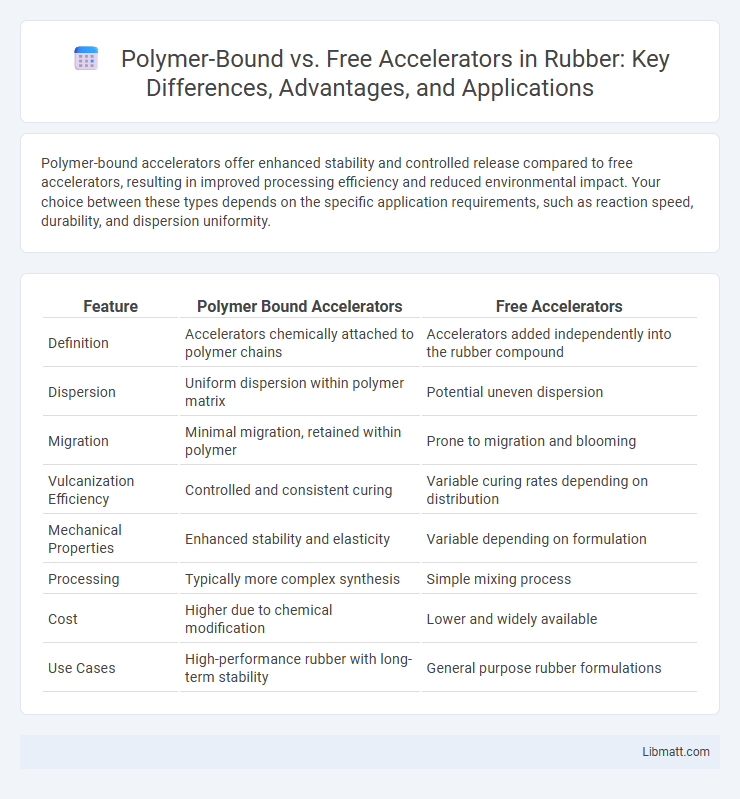

Polymer-bound accelerators offer enhanced stability and controlled release compared to free accelerators, resulting in improved processing efficiency and reduced environmental impact. Your choice between these types depends on the specific application requirements, such as reaction speed, durability, and dispersion uniformity.

Table of Comparison

| Feature | Polymer Bound Accelerators | Free Accelerators |

|---|---|---|

| Definition | Accelerators chemically attached to polymer chains | Accelerators added independently into the rubber compound |

| Dispersion | Uniform dispersion within polymer matrix | Potential uneven dispersion |

| Migration | Minimal migration, retained within polymer | Prone to migration and blooming |

| Vulcanization Efficiency | Controlled and consistent curing | Variable curing rates depending on distribution |

| Mechanical Properties | Enhanced stability and elasticity | Variable depending on formulation |

| Processing | Typically more complex synthesis | Simple mixing process |

| Cost | Higher due to chemical modification | Lower and widely available |

| Use Cases | High-performance rubber with long-term stability | General purpose rubber formulations |

Introduction to Rubber Accelerators

Rubber accelerators enhance the vulcanization process, improving the elasticity, durability, and overall performance of rubber products. Polymer-bound accelerators are chemically attached to the polymer chain, offering controlled crosslinking and reduced migration, while free accelerators exist independently, facilitating faster reaction kinetics but potentially causing uneven distribution. Understanding the differences between polymer-bound and free accelerators can optimize Your rubber formulation for targeted mechanical properties and processing efficiency.

Overview of Polymer Bound Accelerators

Polymer bound accelerators consist of accelerator molecules chemically attached to polymer chains, providing controlled and sustained release during the vulcanization process. These accelerators enhance elastomer curing efficiency, improve process safety by reducing dust and handling hazards, and enable tailored reaction rates ideal for your specific rubber formulation needs. Their unique structure allows for better dispersion and reduced extraction loss compared to free accelerators, resulting in improved mechanical properties and durability of the final rubber product.

What are Free Accelerators?

Free accelerators are chemical additives used in polymer curing processes that exist independently and are not chemically bonded to the polymer matrix. They enhance the reaction rate by facilitating crosslinking between polymer chains, improving processing speed and final material properties. Unlike polymer-bound accelerators, free accelerators may migrate or volatilize, influencing the curing efficiency and mechanical performance of the polymer product.

Key Differences Between Polymer Bound and Free Accelerators

Polymer bound accelerators are chemically attached to a polymer matrix, providing controlled release and enhanced stability during curing processes, whereas free accelerators exist as small molecules that disperse directly into the system for immediate activity. You will find that polymer bound accelerators reduce volatile losses and improve handling safety compared to free accelerators, which can sometimes cause faster but less controlled reactions. The key differences lie in their solubility, reaction kinetics, and impact on final product properties, influencing the choice based on application requirements.

Advantages of Polymer Bound Accelerators

Polymer bound accelerators offer enhanced dispersion within cement matrices, leading to more uniform and controlled curing processes. Their reduced volatility and minimized environmental impact improve safety and sustainability on construction sites. These accelerators also exhibit prolonged activity, increasing efficiency while reducing the risk of premature setting compared to free accelerators.

Drawbacks of Free Accelerators

Free accelerators in polymerization processes often cause uneven distribution, leading to inconsistent curing and reduced mechanical properties in the final product. They may also migrate to the surface or leach out over time, resulting in diminished accelerator effectiveness and potential contamination. This instability can compromise processing efficiency and long-term durability compared to polymer-bound accelerators.

Impact on Rubber Processing and Performance

Polymer bound accelerators enhance rubber processing by providing improved dispersion and reduced migration, resulting in more uniform vulcanization and consistent crosslink density. Free accelerators typically offer faster cure rates but can cause uneven distribution and increased volatility, leading to potential defects and reduced aging resistance in rubber products. The choice between polymer bound and free accelerators directly influences the mechanical properties, durability, and overall performance of elastomers in automotive and industrial applications.

Environmental and Safety Considerations

Polymer bound accelerators reduce environmental impact by minimizing the release of harmful chemicals during processing, offering safer handling compared to free accelerators. Free accelerators often pose higher toxicity risks and potential for skin irritation, demanding stringent safety measures. Choosing polymer bound accelerators enhances your facility's compliance with environmental regulations and promotes worker safety.

Industry Applications and Case Studies

Polymer bound accelerators enhance durability and reusability in rubber processing industries, reducing contamination and improving catalyst efficiency compared to free accelerators. Case studies in automotive tire manufacturing demonstrate increased vulcanization control and extended mold life, translating to cost savings and consistent product quality. Your choice of accelerator can significantly impact processing speed and environmental compliance in large-scale elastomer production.

Future Trends in Accelerator Technology

Polymer bound accelerators offer enhanced dispersion and reduced migration compared to free accelerators, driving research toward more stable and efficient vulcanization processes. Future trends in accelerator technology emphasize eco-friendly formulations with lower toxicity and improved compatibility in green rubber compounds. Innovations are focusing on hybrid systems combining polymer binding with nanotechnology to optimize curing speed and final mechanical properties.

Polymer bound vs Free accelerators Infographic

libmatt.com

libmatt.com