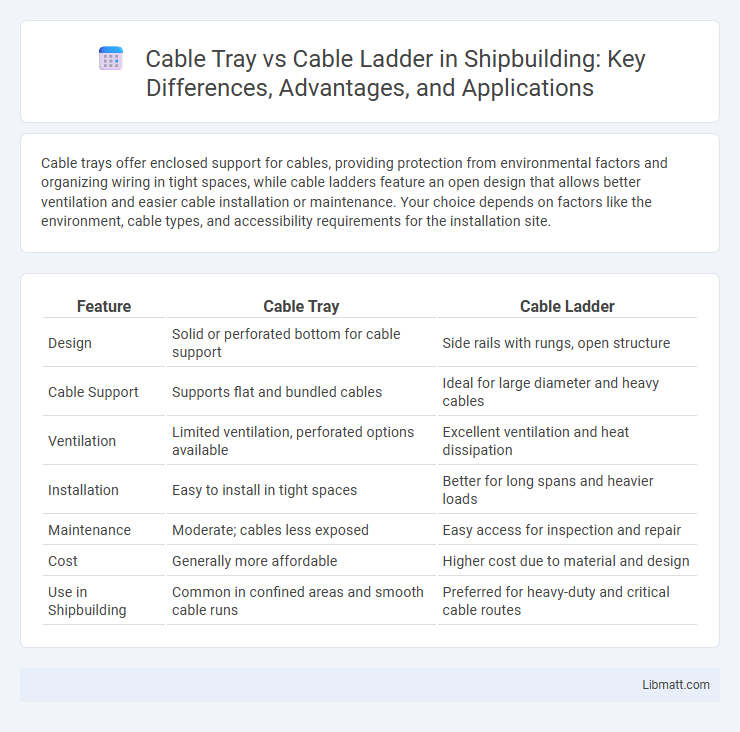

Cable trays offer enclosed support for cables, providing protection from environmental factors and organizing wiring in tight spaces, while cable ladders feature an open design that allows better ventilation and easier cable installation or maintenance. Your choice depends on factors like the environment, cable types, and accessibility requirements for the installation site.

Table of Comparison

| Feature | Cable Tray | Cable Ladder |

|---|---|---|

| Design | Solid or perforated bottom for cable support | Side rails with rungs, open structure |

| Cable Support | Supports flat and bundled cables | Ideal for large diameter and heavy cables |

| Ventilation | Limited ventilation, perforated options available | Excellent ventilation and heat dissipation |

| Installation | Easy to install in tight spaces | Better for long spans and heavier loads |

| Maintenance | Moderate; cables less exposed | Easy access for inspection and repair |

| Cost | Generally more affordable | Higher cost due to material and design |

| Use in Shipbuilding | Common in confined areas and smooth cable runs | Preferred for heavy-duty and critical cable routes |

Introduction to Cable Trays and Cable Ladders

Cable trays and cable ladders serve as essential support systems for electrical wiring, providing organized pathways that protect cables and simplify maintenance. Cable trays typically feature solid or perforated bottoms, making them ideal for supporting and shielding a variety of cable types, while cable ladders consist of parallel side rails connected by rungs, allowing for better ventilation and easier cable inspection. Choosing the right system depends on your installation environment, load requirements, and cable management needs.

Key Differences Between Cable Trays and Cable Ladders

Cable trays are solid or perforated structures designed to support insulated electrical cables, offering protection and organization in enclosed spaces, whereas cable ladders consist of two side rails connected by rungs, providing better ventilation and easier cable access for heavy loads. Cable trays are ideal for light to medium cable loads and environments requiring dust or debris protection, while cable ladders support large bundles of cables and accommodate cable bending with minimal stress. Your choice between the two depends on load capacity, installation environment, and cable management needs.

Material and Construction Comparisons

Cable trays are typically made from materials like aluminum, steel, and fiberglass, offering lightweight options with corrosion resistance suitable for various environments. Cable ladders, commonly constructed from steel or aluminum, feature open rung designs that provide superior ventilation and strength, ideal for supporting heavy cable loads. Your choice depends on the needed durability and environmental conditions, with cable trays favoring enclosed protection and cable ladders emphasizing robust structural support.

Load Capacity: Cable Tray vs Cable Ladder

Cable ladders typically offer higher load capacity compared to cable trays due to their robust, open-rung design, which provides better support and ventilation for heavy cable bundles. Cable trays are often preferred for lighter, more evenly distributed loads and environments requiring partial enclosure. Engineers select the appropriate system by evaluating the weight of cables, installation environment, and airflow requirements to optimize load-bearing efficiency.

Installation Process and Flexibility

Cable trays offer a straightforward installation process with pre-fabricated sections that easily connect, ideal for managing large bundles of cables in linear pathways. Cable ladders provide greater flexibility, supporting cable routing around obstacles and allowing for easier cable access and maintenance due to their open design. Choosing between the two depends on your project's need for rapid installation or adaptable cable management.

Maintenance and Accessibility Considerations

Cable trays offer easier maintenance with solid bottoms that protect cables from dust and debris, reducing the need for frequent cleaning compared to cable ladders. Cable ladders provide superior accessibility for inspection and cable installation because their open-rung design allows for quick visual checks and easier cable handling. Your choice depends on whether ease of cable management or straightforward maintenance access is more critical for the installation environment.

Cost Analysis: Cable Trays vs Cable Ladders

Cable trays typically offer a lower initial cost compared to cable ladders due to simpler manufacturing processes and lighter materials. Maintenance expenses for cable trays are generally reduced since their enclosed design protects cables from environmental damage, minimizing repair and replacement costs. Your choice should consider long-term operational costs alongside upfront investment to optimize total project expenditure.

Applications and Ideal Use Cases

Cable trays excel in environments requiring enclosed, protected cable routing such as data centers and industrial plants, offering robust support for complex wiring systems and ease of cable maintenance. Cable ladders are ideal for heavy-duty applications with large bundle cables, providing superior ventilation and heat dissipation in construction sites and outdoor installations. Your choice between cable tray and cable ladder should align with the specific project needs, considering factors like cable type, load capacity, and environmental exposure.

Safety and Compliance Standards

Cable trays and cable ladders must both adhere to strict safety and compliance standards such as IEC 61537 and NFPA 70 to ensure reliable electrical installations. Cable trays offer enclosed protection, minimizing exposure to dust and accidental contact, which enhances safety in sensitive environments. Your choice should consider these standards to maintain compliance while ensuring safe cable management.

Choosing the Right System for Your Project

Selecting the right cable management system depends on factors such as load capacity, ventilation needs, and ease of installation. Cable trays offer solid, continuous support ideal for lighter cable bundles and protection from debris, while cable ladders provide superior airflow and are better suited for heavy, large-diameter cables. Evaluating your project's cable volume and environmental conditions ensures you choose a cable tray or cable ladder that optimizes safety and performance for your installation.

Cable tray vs cable ladder Infographic

libmatt.com

libmatt.com