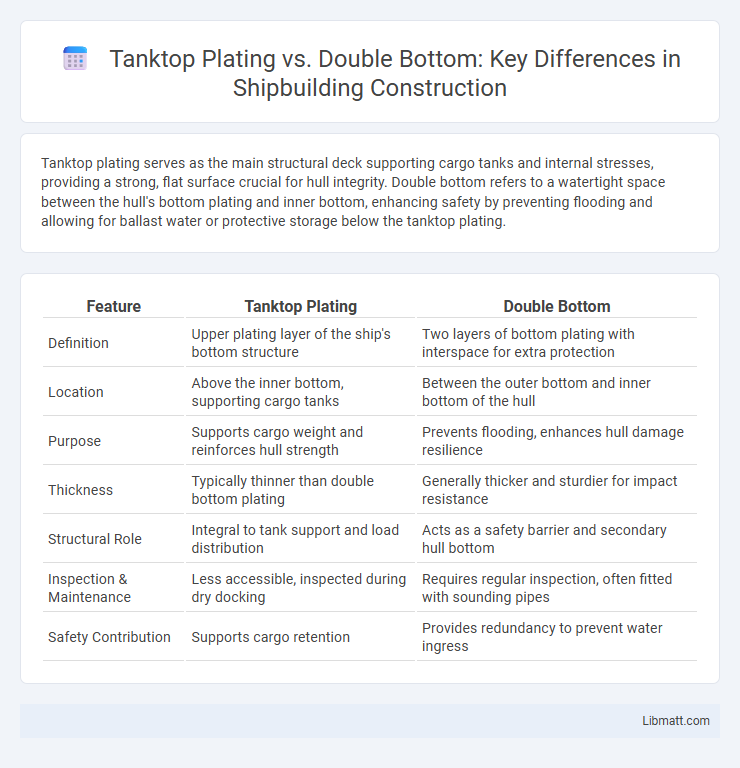

Tanktop plating serves as the main structural deck supporting cargo tanks and internal stresses, providing a strong, flat surface crucial for hull integrity. Double bottom refers to a watertight space between the hull's bottom plating and inner bottom, enhancing safety by preventing flooding and allowing for ballast water or protective storage below the tanktop plating.

Table of Comparison

| Feature | Tanktop Plating | Double Bottom |

|---|---|---|

| Definition | Upper plating layer of the ship's bottom structure | Two layers of bottom plating with interspace for extra protection |

| Location | Above the inner bottom, supporting cargo tanks | Between the outer bottom and inner bottom of the hull |

| Purpose | Supports cargo weight and reinforces hull strength | Prevents flooding, enhances hull damage resilience |

| Thickness | Typically thinner than double bottom plating | Generally thicker and sturdier for impact resistance |

| Structural Role | Integral to tank support and load distribution | Acts as a safety barrier and secondary hull bottom |

| Inspection & Maintenance | Less accessible, inspected during dry docking | Requires regular inspection, often fitted with sounding pipes |

| Safety Contribution | Supports cargo retention | Provides redundancy to prevent water ingress |

Introduction to Tanktop Plating and Double Bottom

Tanktop plating refers to the reinforced steel plating covering the cargo hold's bottom, designed to support heavy cargo and distribute loads evenly across the tanktop structure. The double bottom consists of two layers of watertight hull plating extending along the ship's bottom, providing enhanced safety by preventing flooding in case of outer hull damage. Understanding the distinction between tanktop plating and double bottom construction is crucial for assessing structural integrity and cargo handling in ship design.

Definition and Function of Tanktop Plating

Tanktop plating refers to the thick steel plate covering the top of a ship's double bottom structure, designed to provide extra strength and support to withstand heavy loads and impacts. It primarily functions as a critical structural component that distributes weights evenly and enhances the vessel's overall hull integrity, preventing damage from cargo or machinery above. Unlike the double bottom, which forms an enclosed space between two hull layers for buoyancy and safety, tanktop plating serves as the hard, load-bearing surface within this space.

Definition and Role of Double Bottom

Double bottom is a structural feature in ships consisting of two watertight layers at the bottom, providing extra strength and preventing leakage or flooding from hull breaches. Unlike tanktop plating, which serves as a flat plate covering the cargo tank base, the double bottom integrates with the ship's overall hull structure to improve safety and stability. Your vessel's double bottom plays a critical role in protecting cargo spaces and enhancing the ship's damage resistance during maritime operations.

Structural Differences Between Tanktop Plating and Double Bottom

Tanktop plating serves as a reinforced deck plating located above the double bottom, providing additional hull strength and supporting cargo tanks in oil tankers or bulk carriers. The double bottom consists of two longitudinal watertight decks, forming a space between the outer hull and inner bottom structure that enhances hull integrity and protects against grounding or hull breaches. Structurally, tanktop plating is a continuous, flat steel slab integrated with longitudinal and transverse framing, whereas the double bottom comprises multiple longitudinal and transverse stiffeners creating a cellular structure for strength and damage resistance.

Material Specifications and Thickness Comparison

Tanktop plating typically uses high-tensile steel with a thickness ranging from 16mm to 25mm, designed to withstand concentrated loads and reduce local stresses in the bottom structure of ships. Double bottoms incorporate two layers of steel plating, with the outer bottom plate generally between 15mm and 25mm and the inner tanktop plating matching similar thicknesses to ensure structural integrity and watertightness. Material specifications for both involve stringent requirements for tensile strength, toughness, and corrosion resistance, complying with classification society rules such as those from ABS, DNV, or Lloyd's Register.

Installation and Construction Techniques

Tanktop plating involves welding thick steel plates over the tanktop area of a ship's double bottom, providing a strong, flat surface that supports heavy loads and distributes stress evenly. Double bottom construction consists of two parallel hull bottoms separated by a void space, where the inner bottom is typically formed by tanktop plating, and requires precise alignment and welding to ensure watertight integrity and structural strength. Your choice depends on specific vessel requirements, as tanktop plating demands extensive surface preparation and skilled welding, while double bottom construction integrates multiple plating layers and frames for enhanced safety and durability.

Load Distribution and Stress Management

Tanktop plating provides a continuous, solid surface that evenly distributes loads across the ship's bottom, reducing localized stress and enhancing hull integrity. Double bottoms incorporate an inner hull layer, allowing for more complex load transfer and improved resistance to hull deformation and damage in case of grounding or impact. This design allows double bottoms to effectively manage stress by isolating the cargo tank from potential structural damage, increasing overall safety and durability.

Corrosion Resistance and Maintenance

Tanktop plating offers enhanced corrosion resistance by providing a robust, continuous protective layer that shields the hull from seawater exposure and mechanical damage. Double bottoms, with their compartmentalized design, allow for easier inspection and localized maintenance, reducing the risk of widespread corrosion but requiring diligent upkeep to prevent trapped moisture buildup. Choosing your vessel's plating involves balancing the superior corrosion protection of tanktop plating against the maintenance accessibility benefits of double bottoms.

Cost Implications: Tanktop Plating vs Double Bottom

Tanktop plating generally involves lower initial construction costs compared to double bottom designs, as it requires less steel and fabrication complexity. Double bottom structures offer enhanced safety and liquid containment but increase material and labor expenses, impacting overall project budgets. Your choice between tanktop plating and double bottom should consider long-term maintenance costs alongside upfront expenditures for optimal cost-effectiveness.

Application Scenarios and Best Practices

Tanktop plating is primarily used in the midship sections of bulk carriers and container ships where high compressive strength is needed to support cargo weights, providing enhanced structural integrity against concentrated loads. Double bottom construction, common in oil tankers and chemical carriers, offers superior protection against grounding damage and environmental hazards by incorporating a secondary hull layer that improves safety and prevents pollution. Best practices involve selecting tanktop plating for vessels requiring robust cargo deck support, while double bottoms are ideal for ships prioritizing environmental safety and damage resilience, with routine inspections and corrosion protection critical in both applications.

Tanktop plating vs double bottom Infographic

libmatt.com

libmatt.com