A duct keel is a structural component designed to house and protect systems such as pipes or cables along the centerline of a ship's bottom, while a double bottom consists of two layers of watertight hull plating providing extra strength and safety against grounding or flooding. Your choice between a duct keel and double bottom depends on whether your priority is system protection and maintenance access or enhanced hull integrity and damage resilience.

Table of Comparison

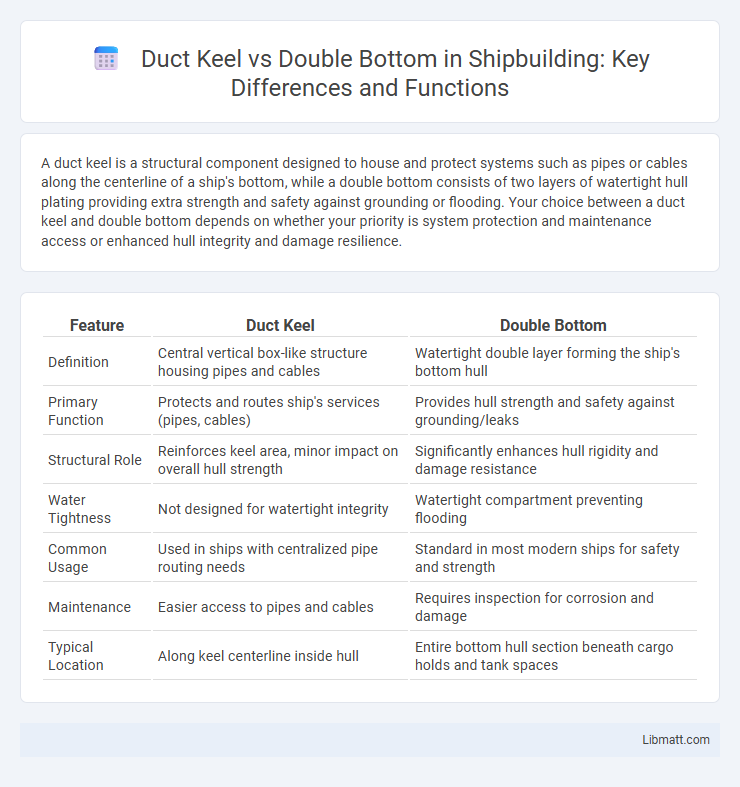

| Feature | Duct Keel | Double Bottom |

|---|---|---|

| Definition | Central vertical box-like structure housing pipes and cables | Watertight double layer forming the ship's bottom hull |

| Primary Function | Protects and routes ship's services (pipes, cables) | Provides hull strength and safety against grounding/leaks |

| Structural Role | Reinforces keel area, minor impact on overall hull strength | Significantly enhances hull rigidity and damage resistance |

| Water Tightness | Not designed for watertight integrity | Watertight compartment preventing flooding |

| Common Usage | Used in ships with centralized pipe routing needs | Standard in most modern ships for safety and strength |

| Maintenance | Easier access to pipes and cables | Requires inspection for corrosion and damage |

| Typical Location | Along keel centerline inside hull | Entire bottom hull section beneath cargo holds and tank spaces |

Introduction to Duct Keel and Double Bottom

Duct keel is a longitudinal structure in ships, running along the bottom centerline, designed to house ballast tanks, piping, and cables, enhancing hull strength and stability. Double bottom refers to a shipbuilding technique involving two layers of watertight hull plating separated by a space, which improves safety by providing additional protection against grounding or hull breaches. Both duct keel and double bottom contribute significantly to the vessel's structural integrity and operational efficiency.

Structural Differences: Duct Keel vs Double Bottom

The duct keel is a narrow, box-like structure running longitudinally along the centerline of a ship's bottom, primarily housing systems like ballast pipes. The double bottom consists of two layers of watertight hull bottom separated by a void space, enhancing hull strength and providing additional buoyancy and protection against grounding or hull breaches. Structurally, the double bottom spans a wider area under the vessel, offering greater reinforcement and damage resistance compared to the localized duct keel.

Functions and Applications of Duct Keel

A duct keel serves primarily as a channel for housing essential systems such as cables, pipelines, and ballast tanks within a ship's hull, providing protection and easy accessibility for maintenance. It functions as a structural element that enhances hull strength and stability by acting as a longitudinal stiffener along the vessel's centerline. Commonly applied in cargo ships and tankers, the duct keel optimizes internal space and contributes to improved weight distribution and damage control compared to a conventional double bottom.

Functions and Applications of Double Bottom

The double bottom serves as a watertight compartment beneath the ship's hull, providing essential buoyancy and protecting the vessel from grounding damage. It is commonly used for storage of ballast water, fuel oil, and freshwater, optimizing space while enhancing stability and safety. This structural design is critical in cargo ships and tankers to prevent pollution and facilitate efficient weight distribution.

Construction Techniques: Duct Keel vs Double Bottom

Duct keel construction involves a central longitudinal structure housing pipes and cables within a single reinforced compartment, providing easy access and protection. Double bottom construction features two layers of watertight steel plates separated by a void space filled with ballast or used for cargo, enhancing the ship's structural strength and safety against grounding or hull breaches. While duct keel emphasizes utility and maintenance accessibility, double bottom prioritizes added buoyancy and damage resistance in shipbuilding.

Advantages of Duct Keel in Ship Design

Duct keels offer significant advantages in ship design by providing enhanced structural strength and improved stability through centralized ballast placement. Their narrow, enclosed structure facilitates easier inspection and maintenance, contributing to safer and more efficient operations. You benefit from reduced hull weight and optimized space utilization, which increases overall vessel performance and fuel efficiency.

Advantages of Double Bottom for Vessel Safety

Double bottoms enhance vessel safety by providing an additional watertight compartment beneath the hull, reducing the risk of flooding during grounding or hull breaches. This structure improves damage stability and minimizes the likelihood of sinking by isolating breaches from the cargo and fuel tanks. The double bottom design also offers extra protection against corrosion and structural stress, extending the vessel's operational lifespan.

Limitations and Challenges: Duct Keel vs Double Bottom

Duct keels have limited structural support compared to double bottoms, making them less effective in resisting heavy loads or grounding damage. Double bottoms offer enhanced safety and strength by providing a continuous watertight space, but they require more complex construction and higher maintenance costs. Both systems face challenges in balancing weight, cost, and space utilization while ensuring sufficient protection for the vessel's hull.

Maintenance and Inspection Considerations

Duct keels require more frequent inspection due to limited access and complex internal structures that can trap moisture and debris, increasing corrosion risk. Double bottoms offer easier maintenance access through larger inspection ports, facilitating regular cleaning and structural evaluation to prevent fatigue and leaks. Your maintenance strategy should consider the design differences to optimize inspection schedules and ensure vessel safety.

Choosing Between Duct Keel and Double Bottom

Choosing between a duct keel and a double bottom depends on the vessel's operational requirements and structural priorities. A duct keel provides a protected passage for piping and cables along the hull centerline, enhancing maintenance access while saving internal space, whereas a double bottom offers increased buoyancy, improved hull strength, and enhanced damage resistance by creating a waterproof compartment below the ship's cargo hold. Ship designers must evaluate factors such as vessel size, stability, safety regulations, and intended cargo type to determine the optimal solution between duct keel and double bottom configurations.

Duct keel vs double bottom Infographic

libmatt.com

libmatt.com