A flanged joint offers easy disassembly and maintenance with bolted connections ideal for systems requiring frequent access, while a butt-welded joint provides a strong, leak-proof seal by fusing pipe ends permanently. You should choose a flanged joint for flexibility and inspection needs, whereas butt-welded joints are preferred for high-pressure and permanent installations.

Table of Comparison

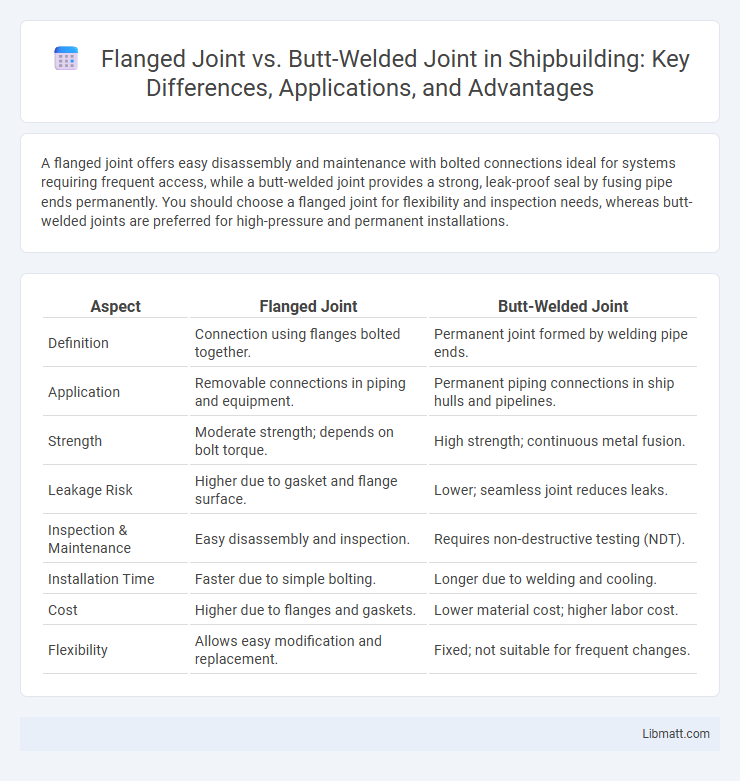

| Aspect | Flanged Joint | Butt-Welded Joint |

|---|---|---|

| Definition | Connection using flanges bolted together. | Permanent joint formed by welding pipe ends. |

| Application | Removable connections in piping and equipment. | Permanent piping connections in ship hulls and pipelines. |

| Strength | Moderate strength; depends on bolt torque. | High strength; continuous metal fusion. |

| Leakage Risk | Higher due to gasket and flange surface. | Lower; seamless joint reduces leaks. |

| Inspection & Maintenance | Easy disassembly and inspection. | Requires non-destructive testing (NDT). |

| Installation Time | Faster due to simple bolting. | Longer due to welding and cooling. |

| Cost | Higher due to flanges and gaskets. | Lower material cost; higher labor cost. |

| Flexibility | Allows easy modification and replacement. | Fixed; not suitable for frequent changes. |

Introduction to Piping Joints

Piping joints such as flanged joints and butt-welded joints are essential components in pipeline construction, providing secure connections between pipe sections. Flanged joints use bolted flanges with gaskets to facilitate assembly and disassembly, making them ideal for maintenance and inspection in pressurized systems. Butt-welded joints create a continuous, strong connection by welding pipe ends together, offering superior strength and leak resistance, often used in high-pressure and high-temperature applications.

Overview of Flanged Joints

Flanged joints consist of two flanges bolted together with a gasket in between to ensure a leak-proof seal, commonly used in piping systems for easy assembly and disassembly. These joints provide strong mechanical connections that can handle high-pressure and high-temperature environments while allowing for inspection and maintenance without cutting the pipe. Your choice of flanged joints benefits from flexibility in installation and reliable sealing compared to butt-welded joints, which require permanent fusion of pipe ends.

Overview of Butt-Welded Joints

Butt-welded joints create a continuous, permanent bond by fusing two metal pieces end-to-end, providing high-strength, leak-proof connections ideal for pipelines and pressure vessels. These joints offer superior structural integrity compared to flanged joints, enabling better resistance to high pressure and temperature conditions. Understanding butt-welded joints helps you choose the right connection for demanding industrial applications requiring durability and minimal maintenance.

Design and Construction Differences

Flanged joints consist of two flanges bolted together with a gasket between them to ensure a tight seal, allowing for easy assembly and disassembly without specialized welding equipment. Butt-welded joints involve directly welding the pipe ends together, creating a continuous, leak-proof connection ideal for high-pressure and high-temperature applications. The design of flanged joints emphasizes modularity and maintenance accessibility, while butt-welded joints prioritize structural integrity and minimal pressure drop.

Installation Processes Compared

Flanged joints require bolting two flanges together with a gasket in between to ensure a tight seal, enabling easier disassembly and maintenance. Butt-welded joints involve welding the ends of two pipes, providing a stronger, permanent connection ideal for high-pressure systems but requiring skilled labor and inspection for installation. Your choice depends on whether ease of installation and maintenance or long-term durability is the priority for your piping system.

Strength and Leak Prevention

Flanged joints provide easier assembly and disassembly but typically offer lower strength and higher leak potential compared to butt-welded joints, which create a continuous, high-strength bond minimizing leak risks. Butt-welded joints ensure superior structural integrity under high pressure and temperature conditions due to their metallurgical fusion, making them ideal for critical pipelines. Proper welding techniques and inspection are essential in butt-welded joints to maintain leak-tight performance and mechanical robustness.

Maintenance and Inspection Needs

Flanged joints require regular maintenance such as gasket replacement and bolt tightening to prevent leaks and ensure joint integrity. Butt-welded joints demand thorough inspection techniques like radiographic testing and ultrasonic testing to detect weld defects and ensure structural continuity. You should consider the ease of access and inspection availability when choosing between these joint types for your specific application.

Cost Analysis: Flanged vs Butt-Welded

Flanged joints typically incur higher initial costs due to the need for precision-machined components and bolting hardware, making them more expensive than butt-welded joints in terms of material and fabrication. Butt-welded joints require skilled labor and specialized equipment for welding, which can increase labor costs but often result in lower material expenses and reduced maintenance costs over time. Overall, butt-welded joints tend to offer better long-term cost efficiency in high-pressure or critical applications, while flanged joints provide cost advantages in systems requiring frequent disassembly or maintenance.

Suitability for Various Applications

Flanged joints are ideal for systems requiring frequent assembly and disassembly, such as piping in chemical plants and water treatment facilities, due to their ease of maintenance and leak-proof sealing with gaskets. Butt-welded joints provide superior strength and corrosion resistance, making them suitable for high-pressure and high-temperature applications like oil and gas pipelines or power plants. Selection depends on operational conditions, where flanged joints offer flexibility and butt welds ensure durability and structural integrity.

Conclusion: Choosing the Right Joint Type

Selecting between a flanged joint and a butt-welded joint depends on factors such as application requirements, ease of maintenance, and pressure ratings. Flanged joints offer the advantage of easy disassembly and reassembly, making them ideal for systems requiring frequent inspection or repairs, while butt-welded joints provide superior strength and leak resistance for high-pressure applications. Your decision should prioritize operational needs, durability, and cost-effectiveness to ensure the optimal joint performance.

Flanged joint vs butt-welded joint Infographic

libmatt.com

libmatt.com