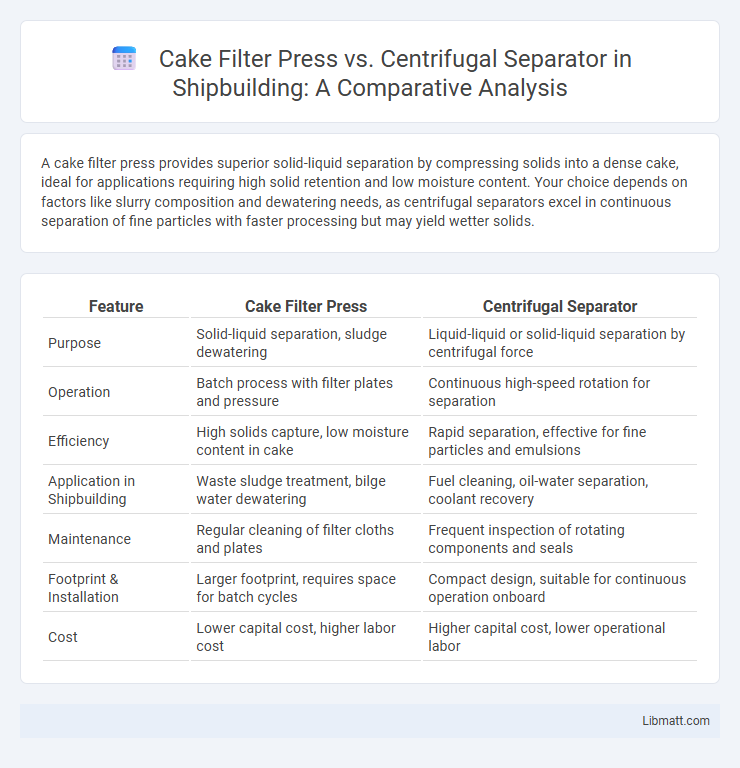

A cake filter press provides superior solid-liquid separation by compressing solids into a dense cake, ideal for applications requiring high solid retention and low moisture content. Your choice depends on factors like slurry composition and dewatering needs, as centrifugal separators excel in continuous separation of fine particles with faster processing but may yield wetter solids.

Table of Comparison

| Feature | Cake Filter Press | Centrifugal Separator |

|---|---|---|

| Purpose | Solid-liquid separation, sludge dewatering | Liquid-liquid or solid-liquid separation by centrifugal force |

| Operation | Batch process with filter plates and pressure | Continuous high-speed rotation for separation |

| Efficiency | High solids capture, low moisture content in cake | Rapid separation, effective for fine particles and emulsions |

| Application in Shipbuilding | Waste sludge treatment, bilge water dewatering | Fuel cleaning, oil-water separation, coolant recovery |

| Maintenance | Regular cleaning of filter cloths and plates | Frequent inspection of rotating components and seals |

| Footprint & Installation | Larger footprint, requires space for batch cycles | Compact design, suitable for continuous operation onboard |

| Cost | Lower capital cost, higher labor cost | Higher capital cost, lower operational labor |

Introduction to Cake Filter Press and Centrifugal Separator

A cake filter press uses pressure filtration to separate solids from liquids, forming a solid cake on filter plates for efficient dewatering, commonly used in wastewater treatment and chemical industries. A centrifugal separator operates on centrifugal force, rapidly spinning mixtures to separate components by density, ideal for applications such as oil purification and dairy processing. Your choice depends on the specific separation needs, including solid content, particle size, and desired clarity of the liquid phase.

How Cake Filter Press Works

A cake filter press operates by pumping slurry into a series of filter plates covered with filter cloth, where pressure forces the liquid through the cloth, leaving solid particles behind to form a filter cake. The press uses hydraulic pressure to compress the plates tightly together, enhancing liquid extraction and producing a dry, compact cake. Your choice of a cake filter press offers precise solid-liquid separation ideal for industries requiring high moisture reduction and clean filtrate.

How Centrifugal Separator Functions

A centrifugal separator operates by spinning a mixture at high speed, using centrifugal force to separate substances of different densities. The heavier solids move outward to the wall of the separator, where they form a cake, while the lighter liquids remain closer to the center and are discharged separately. This process efficiently separates liquids from solids in various industrial applications, such as wastewater treatment and chemical processing.

Key Differences Between Cake Filter Press and Centrifugal Separator

The cake filter press excels in solid-liquid separation by compressing slurry between plates to form a compact cake, offering high dryness and clarity suitable for sludge dewatering. The centrifugal separator uses rotational force to separate components based on density differences, ideal for continuous separation of fine particles and immiscible liquids. Your choice depends on processing needs: cake filter presses provide batch processing with low moisture content, while centrifugal separators enable rapid, continuous operation with finer separation.

Filtration Efficiency Comparison

Cake filter presses achieve higher filtration efficiency by producing drier filter cakes with moisture content as low as 10%, making them ideal for solid-liquid separation in industries requiring precise solid removal. Centrifugal separators are faster and handle larger volumes but typically deliver lower solid dryness, with moisture content around 30-50%, suitable for applications prioritizing throughput over cake dryness. Your choice depends on whether filtration efficiency or processing speed is the primary goal in your separation process.

Applications in Industry

Cake filter presses are widely used in industries such as chemical manufacturing, pharmaceuticals, and food processing for efficient solid-liquid separation, especially where a high degree of dryness in the filter cake is required. Centrifugal separators find applications in waste water treatment, dairy processing, and oil refining, excelling at rapid separation of fine particles or immiscible liquids based on density differences. Both technologies are crucial in mining and mineral processing for dewatering slurries, with the filter press providing superior solids discharge and the centrifugal separator offering continuous operation and high throughput.

Advantages of Cake Filter Press

A cake filter press offers superior solids capture with higher dryness levels, making it ideal for wastewater treatment and slurry dewatering. It provides precise control over filtration cycles and produces a consistent cake structure, reducing disposal costs. Its lower energy consumption and minimal maintenance requirements improve overall operational efficiency compared to centrifugal separators.

Advantages of Centrifugal Separator

Centrifugal separators offer high efficiency in separating fine solid particles from liquids, enabling faster processing times compared to cake filter presses. They operate continuously and handle large volumes with lower labor requirements, making them ideal for industrial applications requiring rapid and automated separation. Their compact design and ability to achieve higher separation speeds result in reduced downtime and improved overall productivity.

Factors to Consider When Choosing a Separation Method

When choosing between a cake filter press and a centrifugal separator, you must evaluate factors such as solids concentration, particle size, and moisture content to determine the most efficient separation method. Cake filter presses provide higher dryness of the solid cake, ideal for applications requiring minimal moisture, while centrifugal separators excel in processing high volumes with lower solids content. Consider your operational needs, including cycle time and maintenance requirements, to select the optimal device tailored to your separation goals.

Conclusion: Choosing the Right Equipment for Your Needs

Cake filter presses provide superior solids dewatering with high dryness levels, making them ideal for applications requiring minimal moisture in the cake. Centrifugal separators excel in continuous operation and efficient separation of fine particles in liquid suspensions, suited for processes with high throughput and rapid clarification needs. Your optimal choice depends on whether you prioritize dryness and batch processing (cake filter press) or speed and continuous separation (centrifugal separator).

Cake filter press vs centrifugal separator Infographic

libmatt.com

libmatt.com