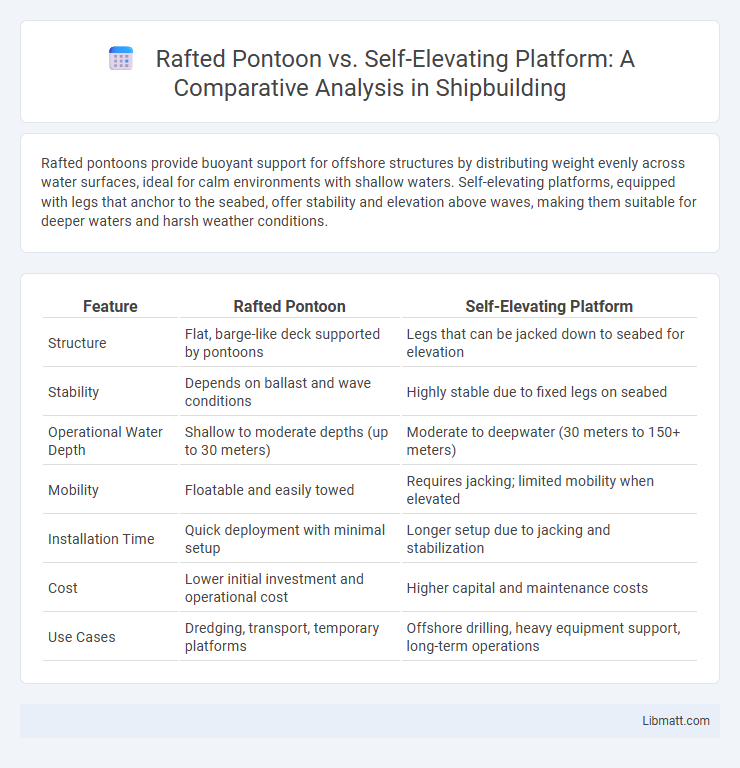

Rafted pontoons provide buoyant support for offshore structures by distributing weight evenly across water surfaces, ideal for calm environments with shallow waters. Self-elevating platforms, equipped with legs that anchor to the seabed, offer stability and elevation above waves, making them suitable for deeper waters and harsh weather conditions.

Table of Comparison

| Feature | Rafted Pontoon | Self-Elevating Platform |

|---|---|---|

| Structure | Flat, barge-like deck supported by pontoons | Legs that can be jacked down to seabed for elevation |

| Stability | Depends on ballast and wave conditions | Highly stable due to fixed legs on seabed |

| Operational Water Depth | Shallow to moderate depths (up to 30 meters) | Moderate to deepwater (30 meters to 150+ meters) |

| Mobility | Floatable and easily towed | Requires jacking; limited mobility when elevated |

| Installation Time | Quick deployment with minimal setup | Longer setup due to jacking and stabilization |

| Cost | Lower initial investment and operational cost | Higher capital and maintenance costs |

| Use Cases | Dredging, transport, temporary platforms | Offshore drilling, heavy equipment support, long-term operations |

Introduction to Rafted Pontoons and Self-Elevating Platforms

Rafted pontoons are large buoyant structures used to support heavy loads on water, providing stability through their wide, flat design. Self-elevating platforms, also known as jack-up rigs, lift themselves above the water surface using extendable legs anchored to the seabed, offering enhanced stability for offshore drilling or construction. Your choice between these depends on factors such as water depth, load requirements, and operational conditions.

Key Structural Differences

Rafted pontoons feature a flat, buoyant base constructed from interconnected pontoons designed to float and distribute weight evenly on water surfaces, providing stability through buoyancy. Self-elevating platforms (jack-up rigs) utilize extendable legs that anchor to the seabed, lifting the platform above the waterline for stability in harsh marine conditions and reduced wave impact. The primary structural difference lies in rafted pontoons relying on flotation and buoyancy, while self-elevating platforms depend on rigid leg support and elevation above the water for operational stability.

Applications and Use Cases

Rafted pontoons are primarily utilized in shallow water dredging, offshore construction, and temporary bridge supports due to their flexible deployment and ease of transportation. Self-elevating platforms, or jack-up rigs, are designed for offshore oil and gas exploration, wind farm installation, and maintenance in deeper waters, providing stable working surfaces by elevating above the sea level. Each platform's application depends on water depth, load capacity, and operational duration, with rafted pontoons favored for mobility and self-elevating platforms preferred for stability in harsh marine environments.

Deployment and Mobility

Rafted pontoons offer rapid deployment and high mobility due to their lightweight structure and ability to be towed easily across water. Self-elevating platforms provide stable, fixed positioning by lowering legs to the seabed, limiting mobility but ensuring a secure work environment in rough sea conditions. Rafted pontoons excel in shallow water and temporary operations, while self-elevating platforms suit longer-term, deepwater deployments with minimal movement.

Operational Stability and Safety

Rafted pontoons offer operational stability through buoyant support and flexible mooring, making them suitable for calm to moderate sea conditions but less effective during severe weather. Self-elevating platforms provide superior stability by lifting the structure above the water on fixed legs, significantly enhancing safety in rough seas and during heavy operations. Your choice depends on prioritizing mobility and cost versus maximum stability and safety in challenging marine environments.

Load Capacity and Performance

Rafted pontoons offer moderate load capacity suitable for lighter offshore operations, typically supporting up to several hundred tons, while self-elevating platforms excel with significantly higher load capacity, often exceeding several thousand tons due to their robust leg structures. Performance-wise, self-elevating platforms provide superior stability and operational efficiency in harsh marine environments by elevating above waves, enabling safer heavy-lift and drilling activities. Rafted pontoons, being dependent on buoyancy alone, are more affected by sea conditions, limiting their effectiveness in rough waters compared to the elevated stance of self-elevating platforms.

Cost Implications and Budget Considerations

Rafted pontoons generally offer lower initial capital expenditure due to simpler design and ease of transport, making them suitable for projects with tighter budgets. Self-elevating platforms, with their complex engineering and enhanced stability, require higher upfront investment but provide long-term cost efficiency through reduced operational delays and maintenance. Your choice should balance immediate budget constraints against potential lifecycle savings and project duration.

Maintenance and Lifespan

Rafted pontoons require regular inspections and corrosion control to prevent structural degradation, with a typical lifespan of 20 to 30 years depending on environmental conditions. Self-elevating platforms benefit from robust design and automated maintenance systems, extending their operational life to 30 to 40 years with scheduled dry-dock servicing. Both structures demand preventive maintenance, but self-elevating platforms generally offer enhanced durability due to their elevated legs reducing exposure to corrosive seawater.

Environmental Impact

Rafted pontoons generally have a lower environmental impact due to their minimal seabed disturbance and easier redeployment, reducing habitat disruption during installation. Self-elevating platforms, with their large steel legs that anchor into the seabed, can cause significant sediment displacement and long-term alteration of marine ecosystems. Your choice between these offshore structures should consider the specific environmental sensitivity of the site to mitigate ecological consequences effectively.

Conclusion: Choosing the Right Platform

Choosing the right offshore platform depends on project requirements, water depth, and environmental conditions. Rafted pontoons provide excellent stability and cost-efficiency for shallow to moderate depths, while self-elevating platforms offer superior adaptability and safety in deeper waters and harsh weather. Your decision should balance operational needs, budget constraints, and site-specific challenges to maximize performance and safety.

Rafted pontoon vs self-elevating platform Infographic

libmatt.com

libmatt.com