Shaft bearings support the rotating shaft within a vessel, ensuring smooth operation and minimizing friction, while stern tube bearings specifically provide alignment and support for the propeller shaft as it passes through the stern tube to prevent water ingress and withstand external pressures. Understanding the differences between these bearings helps you maintain optimal performance and extend the lifespan of your ship's propulsion system.

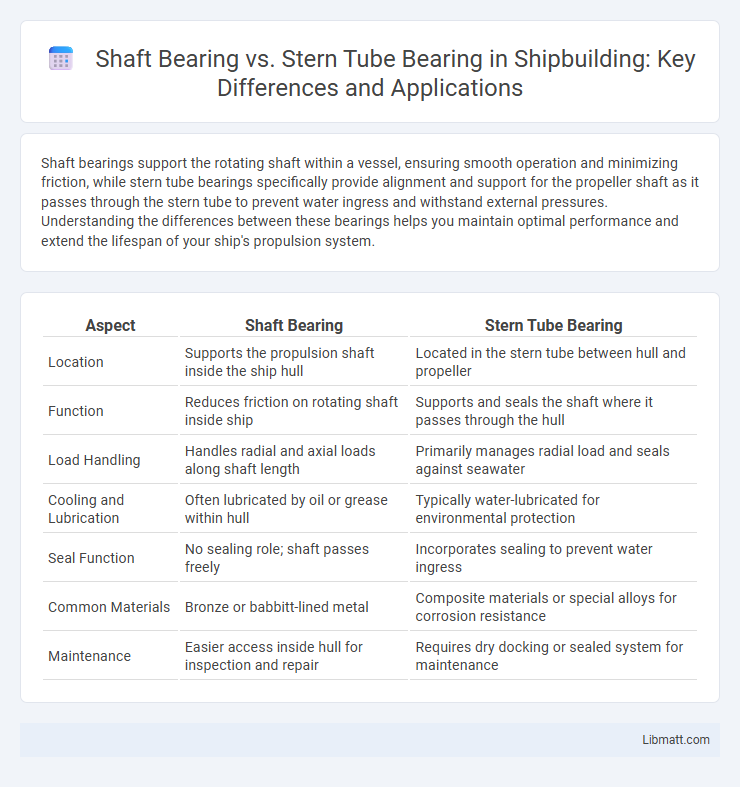

Table of Comparison

| Aspect | Shaft Bearing | Stern Tube Bearing |

|---|---|---|

| Location | Supports the propulsion shaft inside the ship hull | Located in the stern tube between hull and propeller |

| Function | Reduces friction on rotating shaft inside ship | Supports and seals the shaft where it passes through the hull |

| Load Handling | Handles radial and axial loads along shaft length | Primarily manages radial load and seals against seawater |

| Cooling and Lubrication | Often lubricated by oil or grease within hull | Typically water-lubricated for environmental protection |

| Seal Function | No sealing role; shaft passes freely | Incorporates sealing to prevent water ingress |

| Common Materials | Bronze or babbitt-lined metal | Composite materials or special alloys for corrosion resistance |

| Maintenance | Easier access inside hull for inspection and repair | Requires dry docking or sealed system for maintenance |

Introduction to Marine Shaft Bearings

Marine shaft bearings are critical components supporting the propulsion shaft in vessels, ensuring smooth rotation and minimizing wear. Shaft bearings typically include journal bearings, such as stern tube bearings, which are designed to house the propeller shaft within the stern tube and maintain alignment while preventing water ingress. Understanding the differences between shaft bearing types helps optimize your vessel's propulsion system efficiency and reliability.

Overview of Shaft Bearing Systems

Shaft bearing systems are critical for supporting rotating shafts in marine and industrial applications, with shaft bearings designed to handle radial and axial loads through precision-machined surfaces and advanced lubricants. Stern tube bearings specifically support the propeller shaft within the stern tube, providing alignment, reducing friction, and preventing water ingress using either water-lubricated or oil-lubricated designs. Choosing the right bearing system enhances Your vessel's durability and operational efficiency by ensuring optimal load distribution and minimizing wear.

What is a Stern Tube Bearing?

A stern tube bearing is a specialized maritime bearing designed to support the propeller shaft where it exits the hull of a ship, ensuring smooth rotation and minimizing wear. Unlike typical shaft bearings, stern tube bearings are often water-lubricated to withstand marine environments and provide corrosion resistance. Your vessel's proper propulsion and reduced maintenance costs depend significantly on the efficient performance of these critical stern tube bearings.

Key Differences: Shaft Bearing vs Stern Tube Bearing

Shaft bearings support the propulsion shaft within the engine room, primarily handling radial and axial loads, while stern tube bearings are located in the stern tube, sealing the shaft entry point and protecting against water ingress. Shaft bearings typically use roller or journal types designed for high-speed rotation, whereas stern tube bearings often incorporate water-lubricated systems to withstand harsh marine environments. The key difference lies in their location and function: shaft bearings maintain shaft alignment inside the vessel, and stern tube bearings ensure safe, watertight shaft passage through the hull.

Types of Materials Used in Both Bearings

Shaft bearings commonly utilize bronze, stainless steel, and polymer composites for their excellent corrosion resistance and wear properties. Stern tube bearings often feature lignum vitae wood or advanced rubber-lined materials combined with metal alloys to provide superior water lubrication and impact dampening. Both bearing types prioritize materials that enhance durability and reduce friction in marine environments.

Lubrication Methods Compared

Shaft bearings typically use grease or oil lubrication systems, ensuring minimal friction and wear through continuous lubrication either by manual application or automatic oil circulation. Stern tube bearings rely on a flooded lubrication method, where the bearing housing is filled with oil, creating a hydrodynamic film that reduces metal-to-metal contact and extends service life. Your choice between these bearing types depends on the vessel's design and maintenance preferences, as lubrication methods directly impact performance and durability.

Installation and Maintenance Requirements

Shaft bearings generally require more frequent inspection and lubrication to ensure smooth operation, with installation demanding precise alignment to prevent wear and vibrations. Stern tube bearings, often integrated with sealing systems, involve more complex installation procedures to maintain watertight integrity and may require specialized tools for maintenance. Your choice should consider the ease of access for routine servicing and the operating environment's impact on bearing lifespan.

Performance and Efficiency Considerations

Shaft bearings offer high performance with reduced friction, enhancing overall efficiency in propulsion systems by supporting the rotating shaft directly and minimizing energy loss. Stern tube bearings provide robust support and better sealing against water ingress, critical for maintaining long-term reliability and reducing maintenance costs in marine applications. Your choice between shaft bearing and stern tube bearing should consider the balance between operational efficiency and durability requirements for optimal vessel performance.

Common Applications in Marine Engineering

Shaft bearings are commonly used in marine propulsion systems to support and align the rotating propeller shaft, ensuring smooth and efficient operation. Stern tube bearings specifically support the shaft within the stern tube, providing a sealed environment that prevents water ingress while maintaining lubrication in marine vessels. Your choice between shaft bearing and stern tube bearing depends on the specific operational requirements and design constraints of the marine engineering application.

Choosing the Right Bearing for Your Vessel

Selecting the right bearing for your vessel depends on operational conditions and maintenance capabilities; shaft bearings offer lower friction and easier maintenance, ideal for high-speed vessels with frequent service access, while stern tube bearings provide robust sealing and load distribution suitable for heavy-duty applications and long-distance voyages. Material composition and lubrication type also influence performance, with shaft bearings commonly using water-lubricated composite materials and stern tube bearings often incorporating oil-lubricated white metal or rubber bearings for durability. Vessel size, speed, and environmental factors must be carefully evaluated to ensure optimal bearing performance and longevity.

Shaft bearing vs stern tube bearing Infographic

libmatt.com

libmatt.com