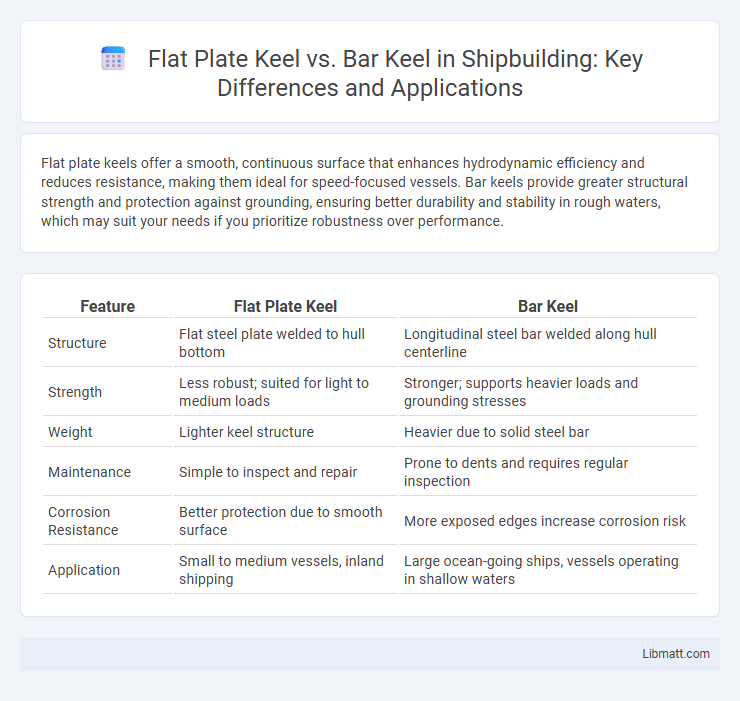

Flat plate keels offer a smooth, continuous surface that enhances hydrodynamic efficiency and reduces resistance, making them ideal for speed-focused vessels. Bar keels provide greater structural strength and protection against grounding, ensuring better durability and stability in rough waters, which may suit your needs if you prioritize robustness over performance.

Table of Comparison

| Feature | Flat Plate Keel | Bar Keel |

|---|---|---|

| Structure | Flat steel plate welded to hull bottom | Longitudinal steel bar welded along hull centerline |

| Strength | Less robust; suited for light to medium loads | Stronger; supports heavier loads and grounding stresses |

| Weight | Lighter keel structure | Heavier due to solid steel bar |

| Maintenance | Simple to inspect and repair | Prone to dents and requires regular inspection |

| Corrosion Resistance | Better protection due to smooth surface | More exposed edges increase corrosion risk |

| Application | Small to medium vessels, inland shipping | Large ocean-going ships, vessels operating in shallow waters |

Introduction to Flat Plate and Bar Keels

Flat plate keels feature a wide, flat steel plate providing buoyancy and stability, commonly used on smaller vessels for easier fabrication and reduced draft. Bar keels consist of a narrow, robust steel bar welded longitudinally along the ship's bottom, offering enhanced protection against grounding and underwater obstacles on larger ships. Understanding the differences between flat plate and bar keels helps you select the optimal design based on vessel size, operating environment, and structural requirements.

Structural Design Differences

Flat plate keels feature a broad, flat structural base that provides extensive surface area and stability, while bar keels consist of a narrow, heavier longitudinal bar offering greater resistance to grounding damage. The flat plate keel uses flat steel plates welded together to form a strong but lighter structure, suitable for vessels requiring minimal draft and improved hydrodynamics. Your choice between these keel types impacts the ship's structural integrity, grounding protection, and overall performance in differing maritime environments.

Material Use and Construction Techniques

Flat plate keels typically utilize thick steel plates welded directly to the hull structure, offering a simpler construction process and reduced material usage compared to bar keels. Bar keels are composed of heavy, solid steel bars or sections bolted or welded to the hull, providing increased durability and impact resistance but requiring more material and complex fabrication techniques. The choice between these keel types depends on factors like vessel size, operational conditions, and cost constraints, with flat plate keels favored in lighter, smaller ships and bar keels preferred for vessels needing enhanced protection.

Hydrodynamic Performance

Flat plate keels offer improved hydrodynamic performance by reducing drag and enhancing flow around the hull, making them suitable for vessels requiring higher speed and fuel efficiency. Bar keels, being more robust and deeper, excel in stability and grounding resistance but tend to create more hydrodynamic drag, affecting overall speed and fuel consumption. Your choice between flat plate and bar keel should balance hydrodynamic efficiency with structural needs based on vessel operation.

Strength and Durability Comparison

Flat plate keels offer moderate strength suitable for smaller vessels, with a simpler construction that can be prone to bending under heavy impacts, while bar keels provide superior strength due to their thicker, more rigid steel bars designed to withstand grounding and heavy loads. The durability of bar keels surpasses flat plate keels as their robust structure resists abrasion and corrosion more effectively, resulting in longer service life and reduced maintenance costs. Shipbuilders often prefer bar keels for large, ocean-going vessels requiring enhanced structural integrity and damage resistance.

Draft and Shape Considerations

Flat plate keels offer a shallow draft design suitable for coastal navigation and shallower waters, enhancing vessel stability with a broad base. Bar keels, characterized by their narrow, deep shape, provide increased protection to the hull in rocky or shallow seabed conditions but result in a deeper draft. Choosing between flat plate and bar keels depends on balancing draft limitations and hull protection based on operational environments.

Maintenance and Repair Aspects

Flat plate keels typically offer easier access for maintenance and repairs due to their smooth, continuous surfaces, which reduce the risk of corrosion and damage accumulation. Bar keels, with their segmented, protruding structure, may require more frequent inspections and specialized welding techniques to address structural wear and corrosion. Your choice depends on balancing repair simplicity with the operational demands of the vessel's hull design.

Suitability for Different Vessel Types

Flat plate keels offer excellent stability and are commonly used on vessels such as barges and small fishing boats, where shallow drafts and easy maintenance are key. Bar keels, with their robust structure, are better suited for large cargo ships and tankers that require heavy-duty impact resistance and improved grounding protection. The choice between flat plate and bar keel depends on vessel size, operational environment, and structural strength requirements.

Cost Implications

Flat plate keels generally incur lower initial fabrication costs due to their simpler design and reduced material requirements, making them economically advantageous for smaller vessels. Bar keels, however, tend to be more expensive upfront because of heavier steel usage and complex welding processes, but they offer enhanced durability and structural strength in rough sea conditions. Maintenance expenses for flat plate keels can be higher over time due to increased susceptibility to damage, whereas bar keels often result in lower long-term repair costs despite their higher initial investment.

Choosing the Right Keel for Your Vessel

Flat plate keels offer a streamlined design suitable for vessels requiring shallow draft and better maneuverability, making them ideal for riverboats and inland watercraft. Bar keels provide superior strength and protection, preferred for ocean-going ships or vessels operating in harsh marine environments due to their robust structure and enhanced resistance to grounding damage. Your choice should balance operational conditions, draft requirements, and structural durability to ensure optimal vessel performance and safety.

Flat plate keel vs bar keel Infographic

libmatt.com

libmatt.com