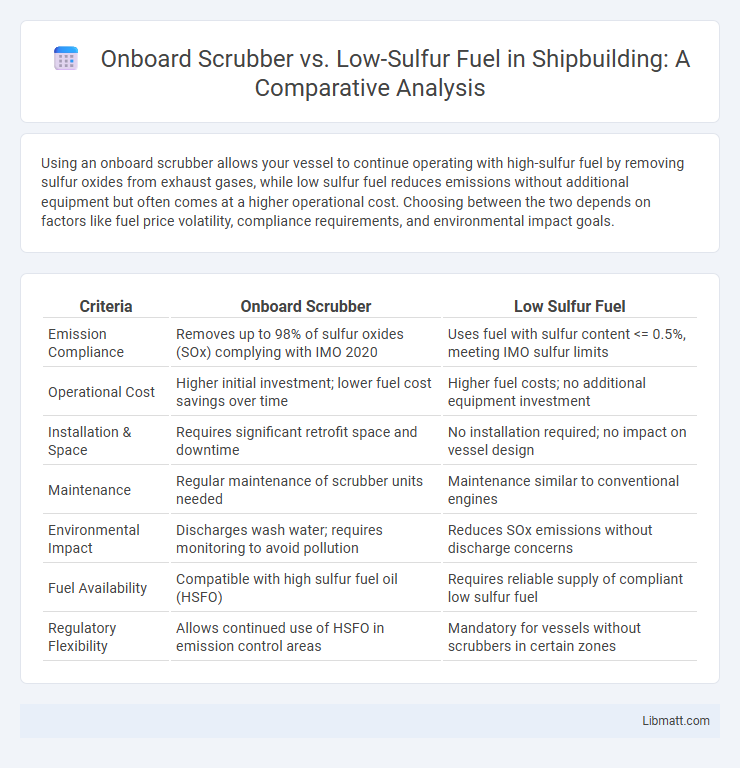

Using an onboard scrubber allows your vessel to continue operating with high-sulfur fuel by removing sulfur oxides from exhaust gases, while low sulfur fuel reduces emissions without additional equipment but often comes at a higher operational cost. Choosing between the two depends on factors like fuel price volatility, compliance requirements, and environmental impact goals.

Table of Comparison

| Criteria | Onboard Scrubber | Low Sulfur Fuel |

|---|---|---|

| Emission Compliance | Removes up to 98% of sulfur oxides (SOx) complying with IMO 2020 | Uses fuel with sulfur content <= 0.5%, meeting IMO sulfur limits |

| Operational Cost | Higher initial investment; lower fuel cost savings over time | Higher fuel costs; no additional equipment investment |

| Installation & Space | Requires significant retrofit space and downtime | No installation required; no impact on vessel design |

| Maintenance | Regular maintenance of scrubber units needed | Maintenance similar to conventional engines |

| Environmental Impact | Discharges wash water; requires monitoring to avoid pollution | Reduces SOx emissions without discharge concerns |

| Fuel Availability | Compatible with high sulfur fuel oil (HSFO) | Requires reliable supply of compliant low sulfur fuel |

| Regulatory Flexibility | Allows continued use of HSFO in emission control areas | Mandatory for vessels without scrubbers in certain zones |

Introduction: Shipping Industry Sulfur Regulations

The International Maritime Organization (IMO) 2020 regulation limits sulfur content in marine fuels to 0.5%, prompting shipping companies to choose between onboard scrubbers and low sulfur fuel to comply. Onboard scrubbers allow vessels to continue using high sulfur fuel oil by removing sulfur oxides from exhaust gases, while low sulfur fuels, such as very low sulfur fuel oil (VLSFO) or marine gas oil (MGO), reduce emissions by using cleaner fuel blends. Both methods aim to meet sulfur oxide (SOx) emission limits, with scrubbers offering long-term cost savings and low sulfur fuels providing immediate compliance without additional equipment.

What Are Onboard Scrubbers?

Onboard scrubbers are advanced exhaust gas cleaning systems installed on ships to reduce sulfur oxide (SOx) emissions by removing sulfur compounds from engine exhaust gases. These systems enable vessels to comply with International Maritime Organization (IMO) sulfur emission regulations while continuing to use higher sulfur content fuels. By treating emissions onboard, scrubbers offer an alternative to low sulfur fuels, potentially lowering operating costs and extending fuel options.

Understanding Low Sulfur Fuels

Low sulfur fuels contain less than 0.5% sulfur content, significantly reducing sulfur oxide (SOx) emissions from ships and complying with IMO 2020 regulations. These fuels are derived through advanced refining processes, ensuring compatibility with existing marine engines while minimizing environmental impact. Using low sulfur fuels eliminates the need for onboard exhaust gas cleaning systems, offering operational simplicity but often at a higher fuel cost compared to high sulfur alternatives with scrubbers.

Compliance with IMO 2020: Scrubber vs Low Sulfur Fuel

Onboard scrubbers enable ships to comply with IMO 2020 sulfur emission limits by allowing the continued use of high sulfur fuel oil (HSFO) while removing sulfur oxides (SOx) from exhaust gases. Low sulfur fuel oil (LSFO) meets IMO 2020 standards by reducing sulfur content to 0.5% m/m or less, eliminating the need for exhaust gas cleaning systems. The choice between scrubbers and low sulfur fuels depends on factors like vessel operation, fuel availability, and cost-effectiveness in achieving Sulfur Oxide Emission Control Area (SECA) compliance.

Environmental Impact Comparison

Onboard scrubbers enable ships to continue using high sulfur fuel while significantly reducing sulfur oxide emissions by cleaning exhaust gases, thus minimizing air pollution and acid rain. Low sulfur fuel inherently produces fewer sulfur oxides and particulate matter, reducing environmental harm at the source without additional equipment. Despite scrubbers lowering sulfur emissions effectively, low sulfur fuel offers a more direct reduction in greenhouse gas pollutants, contributing to improved ocean and air quality overall.

Cost Analysis: Installation and Operational Expenses

Onboard scrubbers require significant initial installation costs, often ranging from $2 million to $5 million per vessel, while low sulfur fuel demands no retrofitting expenses but incurs higher ongoing fuel costs due to price premiums, typically 10-30% above standard marine fuels. Operational expenses for scrubbers include maintenance, energy consumption, and handling of waste byproducts, which can elevate costs but may be offset by the lower price of high sulfur fuel compared to compliant low sulfur alternatives. Your decision should weigh the capital investment against long-term fuel savings and regulatory compliance costs for optimal economic efficiency.

Fuel Availability and Logistics

Onboard scrubbers enable vessels to continue using heavy fuel oil (HFO) by removing sulfur emissions, reducing reliance on low sulfur fuel whose availability can be inconsistent in certain global regions. Low sulfur fuel requires extensive logistical planning due to regional variations in supply, potentially causing delays and increased costs for your shipping operations. Scrubbers offer greater fuel flexibility, mitigating risks associated with fluctuating low sulfur fuel availability and streamlining fleet fuel management.

Maintenance and Operational Considerations

Onboard scrubbers require regular maintenance including cleaning, monitoring of chemical dosing systems, and disposal of wash water residues to ensure optimal performance and compliance with environmental regulations. Low sulfur fuel eliminates the need for complex scrubber systems, reducing maintenance demands but often results in higher fuel costs and potential supply constraints. Operational considerations for scrubbers involve crew training and equipment reliability, whereas low sulfur fuel demands consistent fuel quality verification and compatibility checks with existing engine specifications.

Health and Safety Implications

Onboard scrubbers reduce sulfur oxides emissions but can release harmful particulate matter and chemicals that may affect crew health if not properly managed. Low sulfur fuel minimizes exposure to toxic pollutants, significantly improving air quality and reducing respiratory risks aboard vessels. Your choice impacts the safety protocols needed to protect crew well-being and compliance with environmental health standards.

Future Trends in Marine Sulfur Emissions Compliance

Onboard scrubber systems are increasingly favored for their capability to meet strict International Maritime Organization (IMO) sulfur emission limits while allowing continued use of high-sulfur fuel oil, reducing fuel costs and supply concerns. The marine industry is projected to see a rising adoption of scrubber technology as shipping companies balance regulatory compliance with operational flexibility amid tightening global sulfur caps. Concurrently, low sulfur fuel oils remain essential, especially in emission control areas (ECAs) and regions with limited scrubber retrofitting options, driving innovation in fuel formulations and bunkering infrastructure.

Onboard scrubber vs low sulfur fuel Infographic

libmatt.com

libmatt.com