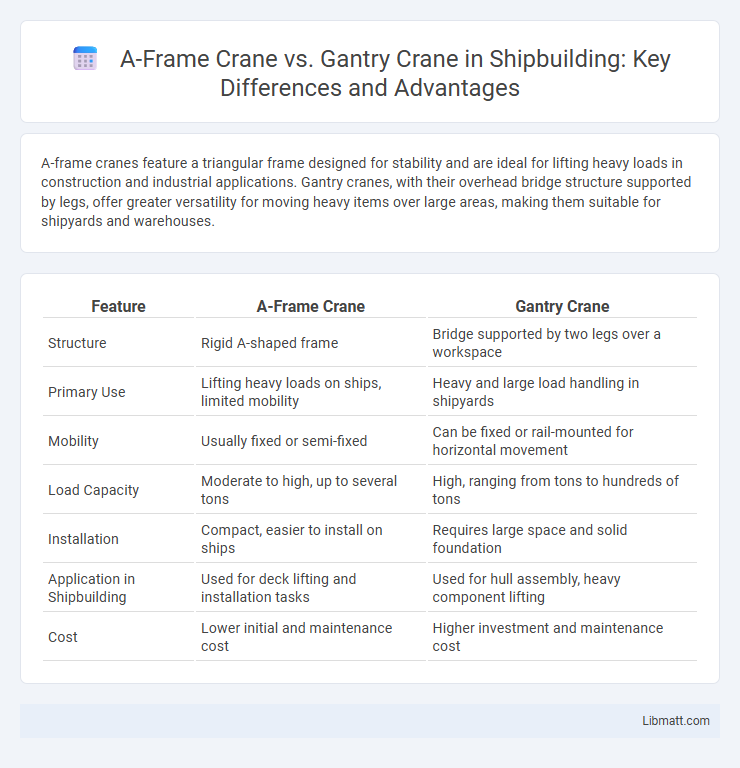

A-frame cranes feature a triangular frame designed for stability and are ideal for lifting heavy loads in construction and industrial applications. Gantry cranes, with their overhead bridge structure supported by legs, offer greater versatility for moving heavy items over large areas, making them suitable for shipyards and warehouses.

Table of Comparison

| Feature | A-Frame Crane | Gantry Crane |

|---|---|---|

| Structure | Rigid A-shaped frame | Bridge supported by two legs over a workspace |

| Primary Use | Lifting heavy loads on ships, limited mobility | Heavy and large load handling in shipyards |

| Mobility | Usually fixed or semi-fixed | Can be fixed or rail-mounted for horizontal movement |

| Load Capacity | Moderate to high, up to several tons | High, ranging from tons to hundreds of tons |

| Installation | Compact, easier to install on ships | Requires large space and solid foundation |

| Application in Shipbuilding | Used for deck lifting and installation tasks | Used for hull assembly, heavy component lifting |

| Cost | Lower initial and maintenance cost | Higher investment and maintenance cost |

Introduction to A-Frame Cranes and Gantry Cranes

A-frame cranes feature a triangular frame structure that provides stability and is commonly used for lifting heavy loads in marine and construction environments. Gantry cranes operate on a bridge supported by freestanding legs that move on a fixed runway, enabling efficient horizontal movement of heavy materials in industrial settings. Your choice between these cranes depends on the specific application requirements, including mobility, load capacity, and workspace constraints.

Structural Design Differences

A-frame cranes feature a triangular frame structure providing stability through two legs meeting at a peak, ideal for lighter loads and limited space. Gantry cranes utilize a horizontal beam supported by vertical legs on wheels or tracks, offering enhanced mobility and capacity for heavy-duty lifting. Your choice depends on the required load capacity and site layout, as gantry cranes accommodate larger materials with versatile movement, unlike the more static A-frame design.

Key Applications and Use Cases

A-frame cranes excel in lifting heavy loads in confined spaces such as shipyards, construction sites, and industrial maintenance due to their portability and ease of setup. Gantry cranes are ideal for extensive material handling in manufacturing plants, warehouses, and outdoor yards, offering higher lifting capacities and the ability to cover larger work areas. Your choice between these cranes hinges on specific operational needs, including load size, spatial constraints, and mobility requirements.

Load Capacity Comparison

A-frame cranes typically offer moderate load capacity suited for lightweight to medium lifting tasks, often ranging from a few tons up to around 50 tons, making them ideal for smaller construction or industrial projects. Gantry cranes usually support significantly higher load capacities, with some models lifting several hundred tons, enabling them to handle large-scale operations such as shipyards, heavy manufacturing, and infrastructure development. When selecting between an A-frame crane and a gantry crane, Your decision should prioritize the specific load requirements of the project to ensure efficiency and safety.

Mobility and Flexibility

A-frame cranes offer superior mobility with their lightweight design and ability to operate in confined spaces, making them ideal for temporary or varied job sites. Gantry cranes provide enhanced flexibility through adjustable spans and heavy load capacities, suitable for stationary tasks in shipyards or warehouses. Your choice depends on whether you prioritize ease of movement or the ability to handle larger, fixed operations.

Installation and Space Requirements

A-frame cranes require minimal installation effort and are ideal for limited space environments due to their compact, triangular frame design, which provides stability without extensive groundwork. Gantry cranes, however, demand more space and a solid foundation for installation, given their large, overhead beam structure supported by legs that can be either fixed or mobile, often needing tracks. Choosing between the two depends on site constraints, with A-frame cranes favored for temporary or confined setups, while gantry cranes suit expansive industrial yards requiring heavy load handling.

Cost Considerations

A-frame cranes generally offer a lower initial investment and reduced maintenance costs due to their simpler design and lighter structural components. Gantry cranes involve higher upfront expenses, including steel framework fabrication and installation, but can handle heavier loads and provide greater versatility, potentially lowering long-term operational costs. Your choice should weigh immediate budget constraints against the specific load requirements and frequency of use to optimize overall cost efficiency.

Safety Features and Risks

A-frame cranes offer enhanced safety through their sturdy triangular frames, providing excellent stability and load distribution, which reduces the risk of tipping during lifts. Gantry cranes feature adjustable legs and secure rail systems, allowing precise control and reducing collision hazards in industrial environments. Understanding these safety features helps you choose the right crane while minimizing operational risks effectively.

Maintenance and Longevity

A-frame cranes require regular lubrication and inspection of pivot points to ensure smooth operation and prevent corrosion, typically resulting in moderate maintenance costs and a lifespan of 15-25 years. Gantry cranes, with robust construction and fewer moving parts exposed to wear, often experience lower maintenance demands and can last 25-40 years when properly serviced. Selecting high-quality materials and adhering to manufacturer-recommended maintenance schedules significantly enhances the longevity and reliability of both crane types in industrial applications.

Choosing the Right Crane for Your Needs

Selecting between an A-frame crane and a gantry crane depends on factors such as workspace size, load capacity, and mobility requirements. A-frame cranes offer a compact design ideal for moderate loads and limited space, while gantry cranes provide higher lifting capacities and versatility for larger industrial applications. Evaluating project-specific needs, including operational environment and budget, ensures the optimal crane choice for efficient material handling.

A-frame crane vs gantry crane Infographic

libmatt.com

libmatt.com