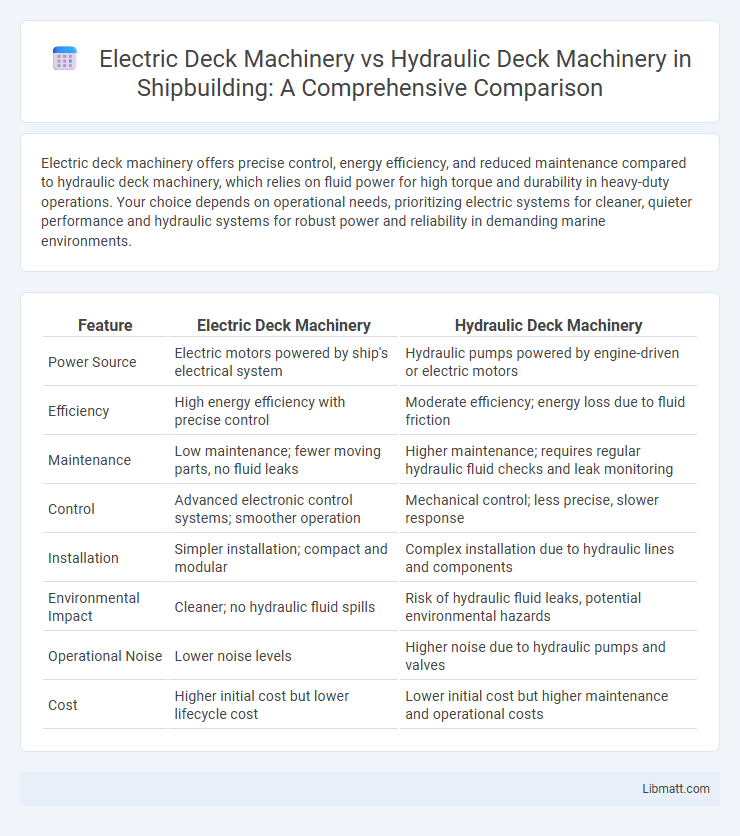

Electric deck machinery offers precise control, energy efficiency, and reduced maintenance compared to hydraulic deck machinery, which relies on fluid power for high torque and durability in heavy-duty operations. Your choice depends on operational needs, prioritizing electric systems for cleaner, quieter performance and hydraulic systems for robust power and reliability in demanding marine environments.

Table of Comparison

| Feature | Electric Deck Machinery | Hydraulic Deck Machinery |

|---|---|---|

| Power Source | Electric motors powered by ship's electrical system | Hydraulic pumps powered by engine-driven or electric motors |

| Efficiency | High energy efficiency with precise control | Moderate efficiency; energy loss due to fluid friction |

| Maintenance | Low maintenance; fewer moving parts, no fluid leaks | Higher maintenance; requires regular hydraulic fluid checks and leak monitoring |

| Control | Advanced electronic control systems; smoother operation | Mechanical control; less precise, slower response |

| Installation | Simpler installation; compact and modular | Complex installation due to hydraulic lines and components |

| Environmental Impact | Cleaner; no hydraulic fluid spills | Risk of hydraulic fluid leaks, potential environmental hazards |

| Operational Noise | Lower noise levels | Higher noise due to hydraulic pumps and valves |

| Cost | Higher initial cost but lower lifecycle cost | Lower initial cost but higher maintenance and operational costs |

Introduction to Deck Machinery: Electric vs Hydraulic

Electric deck machinery offers precise control, energy efficiency, and lower maintenance costs compared to traditional hydraulic systems, which are known for their robust power and reliability in heavy-duty marine operations. Your choice between electric and hydraulic deck machinery should consider factors such as the vessel's operational demands, energy consumption, and ease of integration with existing onboard systems. Modern electric deck machinery increasingly outperforms hydraulic alternatives by providing cleaner operation and enhanced automation capabilities for efficient ship deck management.

Core Differences Between Electric and Hydraulic Systems

Electric deck machinery operates using electric motors and advanced control systems, offering precise speed control, energy efficiency, and lower maintenance compared to hydraulic systems. Hydraulic deck machinery relies on fluid power to generate force, providing high torque and robust performance suitable for heavy-duty lifting tasks but requires regular maintenance for pumps and fluid systems. Core differences include energy consumption, maintenance complexity, operational precision, and suitability for varying load demands on ship decks.

Energy Efficiency: Electric and Hydraulic Deck Machinery

Electric deck machinery offers superior energy efficiency by converting electrical power directly into mechanical energy with minimal loss, resulting in lower operational costs and reduced environmental impact. Hydraulic deck machinery relies on fluid power, which typically experiences energy loss through heat and leakage, making it less efficient than electric systems. Your choice of electric machinery can lead to significant energy savings and a smaller carbon footprint on deck operations.

Installation and Maintenance Considerations

Electric deck machinery offers simpler installation due to fewer components and reduced hydraulic plumbing requirements, lowering initial setup time and costs. Maintenance demands for electric systems are generally less intensive, with fewer leak risks and easier diagnostics compared to hydraulic machinery, which requires regular fluid checks and potential seal replacements. Your choice should consider the operational environment and available technical expertise to optimize lifecycle efficiency.

Performance and Reliability Comparison

Electric deck machinery offers precise control and consistent performance with minimal maintenance due to fewer moving parts and advanced electronic systems. Hydraulic deck machinery provides robust power and durability in heavy-duty applications, excelling in high-torque tasks but often requires more frequent maintenance to ensure reliability. Your choice between electric and hydraulic systems should consider operational demands and maintenance capabilities to optimize performance and reliability.

Safety Aspects of Electric and Hydraulic Deck Machinery

Electric deck machinery offers enhanced safety features such as reduced risk of oil leaks and lower fire hazards compared to hydraulic systems, which rely on pressurized fluids that can cause slips or environmental contamination. Hydraulic deck machinery requires strict maintenance to prevent hose bursts and fluid leaks, posing injury risks and operational downtime. Prioritizing electric deck machinery improves your vessel's safety by minimizing hazardous exposure and simplifying emergency response procedures.

Environmental Impact and Sustainability

Electric deck machinery produces significantly lower greenhouse gas emissions compared to hydraulic deck machinery, promoting a cleaner environment. Your choice of electric machinery reduces dependence on fossil fuels, supports renewable energy integration, and minimizes oil leakage risks. Sustainable operations benefit from lower noise pollution and reduced waste, making electric systems a more eco-friendly solution for maritime applications.

Cost Analysis: Initial Investment and Lifecycle Costs

Electric deck machinery typically demands a higher initial investment compared to hydraulic systems, driven by advanced technology and energy efficiency components. Over the lifecycle, electric machinery often reduces operational costs due to lower energy consumption and decreased maintenance needs from fewer moving parts and absence of hydraulic fluids. Your total cost of ownership may favor electric systems if you prioritize long-term savings and environmentally friendly operation despite the upfront expense.

Industry Applications and Suitability

Electric deck machinery offers precise control and energy efficiency, making it ideal for industries requiring frequent positioning tasks, such as shipping and offshore wind farms. Hydraulic deck machinery delivers high power and durability, suited for heavy-duty marine operations like towing, anchor handling, and dredging, where robust force is essential. Your choice depends on the operational demands, with electric systems excelling in environmental sustainability and maintenance ease, while hydraulic systems provide superior strength in demanding conditions.

Future Trends in Deck Machinery Technology

Electric deck machinery is increasingly favored for its energy efficiency, precise control, and reduced emissions, driving innovation in automation and remote operation systems within maritime industries. Hydraulic deck machinery remains popular for its robustness and high power output but is gradually being integrated with electric components to enhance performance and sustainability. Future trends emphasize hybrid systems, smart sensors, and IoT integration to optimize maintenance, reduce downtime, and improve safety on vessels.

Electric deck machinery vs hydraulic deck machinery Infographic

libmatt.com

libmatt.com