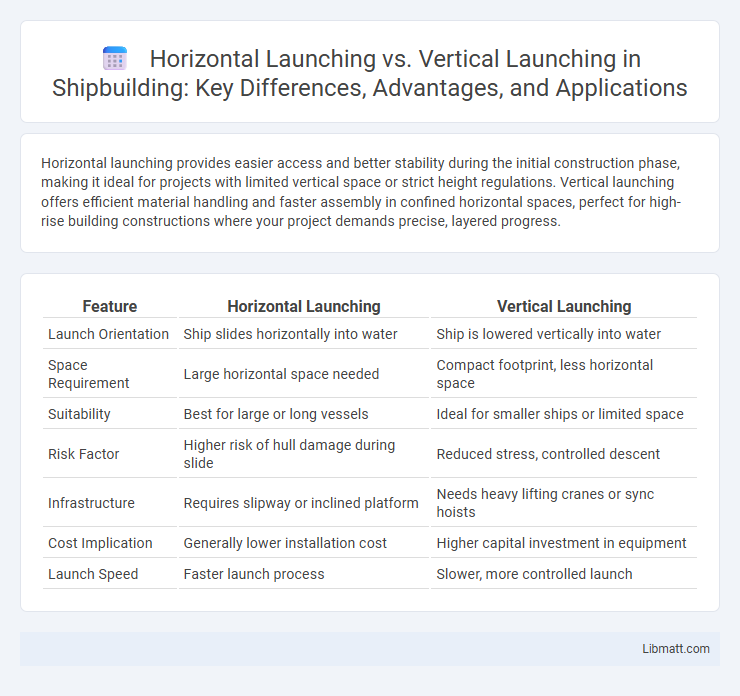

Horizontal launching provides easier access and better stability during the initial construction phase, making it ideal for projects with limited vertical space or strict height regulations. Vertical launching offers efficient material handling and faster assembly in confined horizontal spaces, perfect for high-rise building constructions where your project demands precise, layered progress.

Table of Comparison

| Feature | Horizontal Launching | Vertical Launching |

|---|---|---|

| Launch Orientation | Ship slides horizontally into water | Ship is lowered vertically into water |

| Space Requirement | Large horizontal space needed | Compact footprint, less horizontal space |

| Suitability | Best for large or long vessels | Ideal for smaller ships or limited space |

| Risk Factor | Higher risk of hull damage during slide | Reduced stress, controlled descent |

| Infrastructure | Requires slipway or inclined platform | Needs heavy lifting cranes or sync hoists |

| Cost Implication | Generally lower installation cost | Higher capital investment in equipment |

| Launch Speed | Faster launch process | Slower, more controlled launch |

Introduction to Horizontal and Vertical Launching

Horizontal launching involves deploying vessels or heavy structures by sliding them into the water from a horizontal position, commonly used for ships and offshore platforms. Vertical launching, by contrast, entails lowering structures straight down into the water or onto a foundation, often applied in the installation of offshore wind turbines and subsea equipment. Your choice between horizontal and vertical launching depends on factors like site conditions, structure type, and available space, optimizing safety and efficiency.

Key Differences Between Horizontal and Vertical Launch

Horizontal launching involves moving a spacecraft horizontally on a runway before liftoff, commonly used by spaceplanes like the Space Shuttle, whereas vertical launching propels rockets straight upward from a launchpad, typical for most orbital vehicles. Horizontal launches require extensive runway infrastructure and allow for aircraft-like maneuverability, while vertical launches demand strong thrust engines and precise trajectory control to escape Earth's gravity. The choice between horizontal and vertical launching depends on mission requirements, vehicle design, and payload capacity, impacting cost, complexity, and reusability.

Physics Behind Horizontal Launching

Horizontal launching relies on the principles of projectile motion where an object is propelled along a horizontal plane, balancing aerodynamic lift and drag forces while gravity influences its vertical descent. The velocity imparted at launch determines the range and trajectory, with initial horizontal speed playing a crucial role in overcoming resistance and maintaining stability. Understanding the physics behind horizontal launching helps optimize your design for maximum distance and efficient energy use.

Mechanics of Vertical Launching

Vertical launching involves propelling a vessel from a shipbuilding berth directly into the water using gravity and controlled descent mechanisms. The mechanics require precise alignment with support structures to ensure stability and prevent damage during the drop, often incorporating slipways or caissons. Your project benefits from the efficient use of space and reduced water depth constraints compared to horizontal launching methods.

Advantages of Horizontal Launching

Horizontal launching offers advantages such as easier handling and transport of large or heavy modules due to the alignment with the ground. This method reduces the need for complex lifting equipment and enhances safety by minimizing risks associated with vertical hoisting. You benefit from streamlined assembly processes and lower operational costs when opting for horizontal launching in construction or marine projects.

Benefits of Vertical Launching

Vertical launching offers significant benefits such as improved safety by allowing rockets to lift off directly upward, minimizing risks from wind shear and ground obstacles. It enhances payload capacity due to more efficient thrust alignment and reduces structural stress during ascent. This method also provides greater flexibility for multi-directional orbit insertions, improving mission versatility.

Limitations and Challenges of Each Launch Method

Horizontal launching faces limitations such as requiring extensive runway length and complex ground support infrastructures, which may restrict launch site locations and increase costs. Vertical launching encounters challenges including the need for advanced stabilization systems to maintain rocket balance during liftoff and the difficulty of managing intense aerodynamic forces and vibrations. Your choice between these methods should consider these constraints alongside mission objectives and launch vehicle design.

Applications in Aerospace and Engineering

Horizontal launching is predominantly used for large rockets and spacecraft due to easier ground handling, assembly, and integration with aircraft hangars, making it ideal for heavy-lift aerospace applications. Vertical launching is favored in missile technology and satellite deployment thanks to its compact launch footprint and rapid launch readiness, crucial for military and commercial space missions. Both methods are integral to engineering designs that optimize structural load distribution and enhance launch vehicle performance in diverse aerospace environments.

Safety Considerations in Launch Operations

Horizontal launching offers enhanced stability and reduced risk of structural damage during launch due to gradual elevation transition, making it safer for sensitive payloads. Vertical launching presents higher risks from gravitational stress and requires robust support systems to mitigate dangerous vibrations and potential explosive failures. Your choice of launching method directly impacts safety protocols, contingency planning, and risk mitigation strategies crucial for mission success.

Future Trends in Launch Technology

Future trends in launch technology emphasize the integration of reusable systems and rapid deployment capabilities, with horizontal launching offering advantages in operational flexibility and cost-effectiveness. Vertical launching continues to dominate for heavy payloads due to its efficiency in achieving optimal thrust-to-weight ratios and higher payload capacity. Your strategic choice between these methods will be influenced by advancements in autonomous recovery, modular design, and environmental sustainability goals shaping the aerospace industry's trajectory.

Horizontal launching vs vertical launching Infographic

libmatt.com

libmatt.com