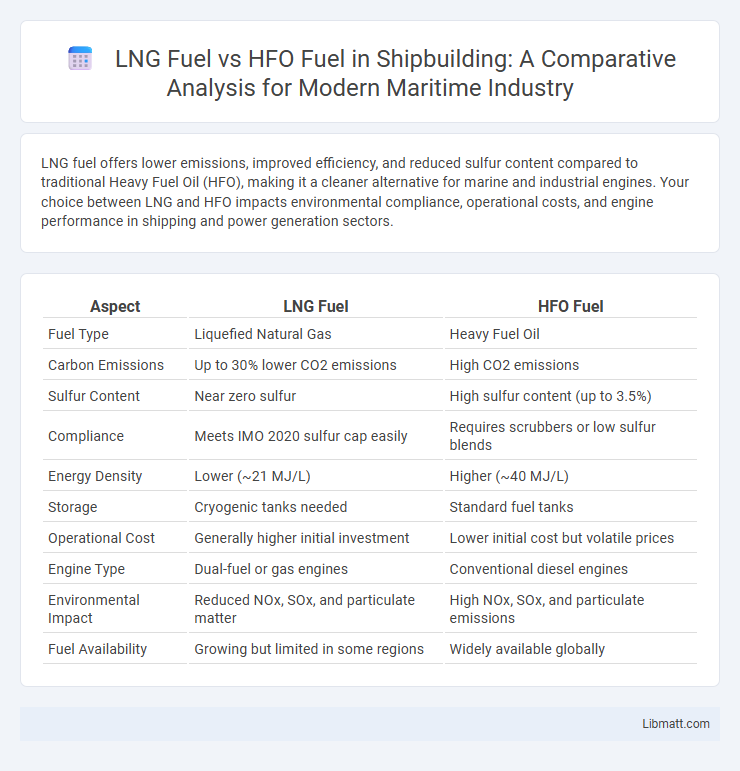

LNG fuel offers lower emissions, improved efficiency, and reduced sulfur content compared to traditional Heavy Fuel Oil (HFO), making it a cleaner alternative for marine and industrial engines. Your choice between LNG and HFO impacts environmental compliance, operational costs, and engine performance in shipping and power generation sectors.

Table of Comparison

| Aspect | LNG Fuel | HFO Fuel |

|---|---|---|

| Fuel Type | Liquefied Natural Gas | Heavy Fuel Oil |

| Carbon Emissions | Up to 30% lower CO2 emissions | High CO2 emissions |

| Sulfur Content | Near zero sulfur | High sulfur content (up to 3.5%) |

| Compliance | Meets IMO 2020 sulfur cap easily | Requires scrubbers or low sulfur blends |

| Energy Density | Lower (~21 MJ/L) | Higher (~40 MJ/L) |

| Storage | Cryogenic tanks needed | Standard fuel tanks |

| Operational Cost | Generally higher initial investment | Lower initial cost but volatile prices |

| Engine Type | Dual-fuel or gas engines | Conventional diesel engines |

| Environmental Impact | Reduced NOx, SOx, and particulate matter | High NOx, SOx, and particulate emissions |

| Fuel Availability | Growing but limited in some regions | Widely available globally |

Introduction to LNG and HFO Fuels

LNG fuel, or liquefied natural gas, is a cleaner alternative to heavy fuel oil (HFO) used primarily in maritime shipping and power generation, offering significantly lower emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter. HFO, a residual fuel derived from crude oil refining, is widely used due to its low cost but generates high levels of pollutants and greenhouse gases, making it less environmentally friendly. Your choice between LNG and HFO fuels impacts operational costs, regulatory compliance, and environmental footprint, with LNG emerging as a preferred option under stricter global emission standards.

Composition and Production Processes

LNG fuel primarily consists of methane (CH4) and is produced by cooling natural gas to approximately -162degC to liquefy it for efficient storage and transport, resulting in a cleaner-burning fuel with lower sulfur and carbon emissions. HFO (Heavy Fuel Oil) is a residual petroleum product derived from the distillation of crude oil, characterized by a high viscosity and sulfur content, requiring extensive refining and treatment processes to meet marine fuel standards. Your choice between LNG and HFO impacts not only engine performance but also compliance with increasingly strict environmental regulations targeting sulfur oxides (SOx) and nitrogen oxides (NOx) emissions.

Energy Density and Efficiency Comparison

LNG fuel offers a lower energy density of approximately 21 MJ/L compared to HFO's 40 MJ/L, impacting storage volume requirements on vessels. Despite lower volumetric energy, LNG enables higher combustion efficiency and cleaner burning, reducing engine maintenance and emissions. Your choice between LNG and HFO fuels should balance storage logistics with operational efficiency and environmental compliance.

Environmental Impacts and Emissions

LNG fuel significantly reduces sulfur oxides (SOx) and nitrogen oxides (NOx) emissions compared to heavy fuel oil (HFO), leading to lower acid rain and smog formation. Methane slip from LNG combustion poses a challenge, but overall greenhouse gas emissions, including CO2, are lowered by up to 25% relative to HFO. LNG's minimal particulate matter output also contributes to improved air quality and compliance with stringent maritime environmental regulations such as IMO Tier III standards.

Regulatory Compliance and Future Trends

LNG fuel offers significant advantages over HFO in meeting stringent IMO regulations, including lower sulfur emissions and reduced greenhouse gases, making it a preferred choice for compliance with IMO 2020 sulfur caps and upcoming carbon reduction targets. Future trends indicate a shift towards LNG as a transitional marine fuel due to its cleaner combustion and compatibility with emerging carbon-neutral fuels, aligning with global decarbonization efforts. Choosing LNG fuel supports your vessel's regulatory compliance and positions it for adaptability in an evolving regulatory environment focused on sustainability.

Operational Considerations and Safety

LNG fuel offers significant operational advantages over HFO fuel, including reduced engine maintenance due to cleaner combustion and lower sulfur emissions, which comply with stringent environmental regulations. Handling LNG requires specialized cryogenic storage systems and trained personnel to manage boil-off gas and prevent leaks, emphasizing the importance of robust safety protocols. Your choice between LNG and HFO fuels should carefully weigh these operational complexities and safety measures to optimize vessel performance and regulatory compliance.

Economic Analysis: Costs and Availability

LNG fuel generally offers lower operating costs compared to Heavy Fuel Oil (HFO) due to higher energy efficiency and reduced maintenance requirements, though initial investment in infrastructure can be significant. Availability of LNG is expanding rapidly with the growth of global liquefaction and regasification terminals, improving supply security and price stability relative to the more established but volatile HFO market. Economic analysis must consider fluctuating market prices, regulatory pressures on emissions, and total cost of ownership when comparing LNG and HFO fuels for maritime and industrial applications.

Infrastructure and Storage Requirements

LNG fuel requires specialized cryogenic storage tanks maintained at extremely low temperatures to keep the liquefied gas stable, while HFO fuel utilizes standard heated tanks to prevent thickening and ensure fluidity. LNG infrastructure demands advanced fueling stations and insulated pipelines compatible with low temperatures, whereas HFO relies on more established, widely available bunkering facilities and handling equipment. Your choice between LNG and HFO fuel significantly impacts vessel design and port infrastructure due to these differing storage and supply challenges.

Adoption in Maritime and Industrial Sectors

LNG fuel is rapidly gaining traction in maritime and industrial sectors due to its lower emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and carbon dioxide (CO2) compared to heavy fuel oil (HFO). Maritime vessels equipped with LNG engines benefit from compliance with stringent International Maritime Organization (IMO) regulations, making LNG a preferred choice for environmentally conscious shipping companies. Your decision to adopt LNG can enhance sustainability while reducing operational costs and environmental impact in industrial applications.

Future Outlook of Marine Fuel Alternatives

Liquefied Natural Gas (LNG) is increasingly favored over Heavy Fuel Oil (HFO) due to its lower sulfur content and reduced greenhouse gas emissions, aligning with International Maritime Organization (IMO) regulations targeting carbon intensity. The future outlook for marine fuel alternatives highlights LNG as a transitional fuel while advancements in hydrogen, ammonia, and biofuels signal a shift towards zero-emission solutions. Your vessel's compliance and sustainability goals can benefit from integrating LNG now while preparing for next-generation fuels in the evolving maritime landscape.

LNG fuel vs HFO fuel Infographic

libmatt.com

libmatt.com