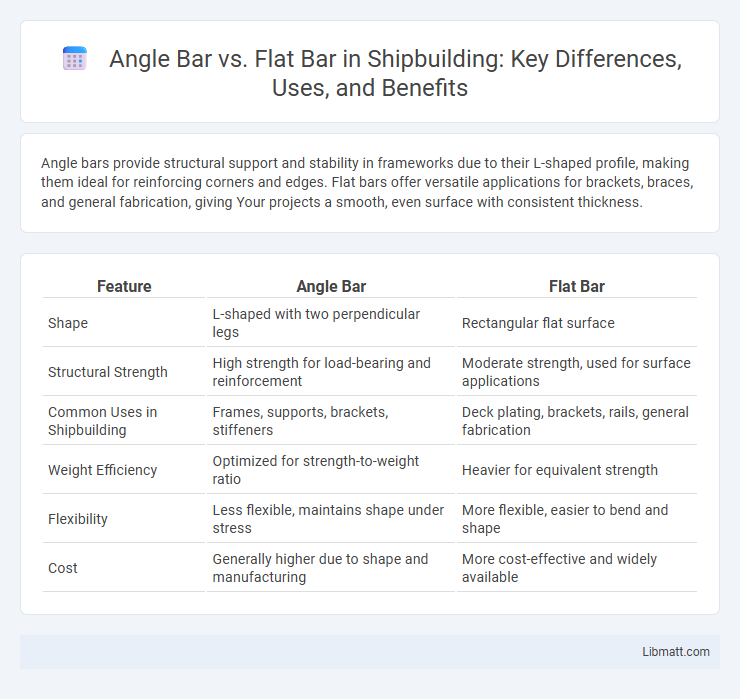

Angle bars provide structural support and stability in frameworks due to their L-shaped profile, making them ideal for reinforcing corners and edges. Flat bars offer versatile applications for brackets, braces, and general fabrication, giving Your projects a smooth, even surface with consistent thickness.

Table of Comparison

| Feature | Angle Bar | Flat Bar |

|---|---|---|

| Shape | L-shaped with two perpendicular legs | Rectangular flat surface |

| Structural Strength | High strength for load-bearing and reinforcement | Moderate strength, used for surface applications |

| Common Uses in Shipbuilding | Frames, supports, brackets, stiffeners | Deck plating, brackets, rails, general fabrication |

| Weight Efficiency | Optimized for strength-to-weight ratio | Heavier for equivalent strength |

| Flexibility | Less flexible, maintains shape under stress | More flexible, easier to bend and shape |

| Cost | Generally higher due to shape and manufacturing | More cost-effective and widely available |

Introduction to Angle Bar and Flat Bar

Angle bars and flat bars are essential steel products used in construction and fabrication industries. Angle bars feature an L-shaped cross-section, providing stability and support in structural applications, while flat bars have a rectangular shape ideal for general-purpose uses like framing and reinforcements. Understanding the differences in shape and strength helps you select the right material for your specific project requirements.

Key Differences Between Angle Bar and Flat Bar

Angle bars feature an L-shaped cross-section with two perpendicular legs, offering excellent structural support in frameworks, while flat bars have a rectangular flat profile ideal for general fabrication and reinforcement tasks. Angle bars provide higher rigidity and load-bearing capacity due to their shape, making them suitable for construction and heavy-duty applications, whereas flat bars are more versatile for everyday metalworking and custom projects. Understanding these distinctions helps you select the right material for strength requirements and design specifics in your construction or manufacturing work.

Structural Properties and Strength Comparison

Angle bars provide superior strength and rigidity due to their L-shaped cross-section, offering excellent resistance to bending and torsion, making them ideal for structural support. Flat bars, while versatile and easier to fabricate, have lower load-bearing capacity and are more prone to bending under heavy loads compared to angle bars. Your choice depends on the structural demands, with angle bars preferred for frameworks needing high strength and flat bars suitable for lighter, less critical applications.

Common Applications of Angle Bars

Angle bars are widely used in construction and manufacturing for structural support in frameworks, reinforcing bridges, and fabricating equipment racks. Their L-shaped cross-section provides excellent load-bearing capacity, making them ideal for corner bracing and edge protection in metalworking projects. Common applications also include shelving units, vehicle chassis, and machinery frames where increased strength and stability are essential.

Typical Uses for Flat Bars

Flat bars are primarily used in construction for framing, supports, and braces due to their uniform thickness and wide surface area. Your fabrication projects often benefit from flat bars when creating brackets, reinforcements, or base plates where flatness and stability are essential. They are also common in manufacturing machinery parts, automotive frames, and shipbuilding.

Material Choices and Finishes for Bars

Angle bars and flat bars are typically made from materials like carbon steel, stainless steel, and aluminum, each offering distinct strength and corrosion resistance qualities suitable for diverse applications. Finish options such as hot-dip galvanizing, powder coating, and anodizing enhance durability and aesthetic appeal according to environmental exposure and design preferences. Your choice between angle and flat bars should account for these material and finish variations to meet structural requirements and longevity expectations.

Installation and Fabrication Considerations

Angle bars offer easier installation due to their L-shaped profile, providing better stability and straightforward alignment in structural frameworks. Flat bars require precise cutting and welding techniques to ensure secure fabrication, often demanding additional support components for load-bearing applications. Choosing between angle bars and flat bars depends on project requirements, with angle bars favored for rigidity and flat bars preferred for versatile shaping in custom fabrications.

Cost Comparison: Angle Bar vs Flat Bar

Angle bars generally cost less per linear foot compared to flat bars due to their lower material volume and simpler manufacturing process. Flat bars require more steel, increasing weight and expense, especially in thicker gauges or wider widths. The choice between angle bars and flat bars significantly impacts project budgets, with angle bars offering cost-effective solutions for structural framing and bracing applications.

Advantages and Disadvantages of Each Bar Type

Angle bars offer excellent strength and stability due to their L-shaped design, making them ideal for structural applications requiring support and reinforcement; however, their shape can limit surface contact in certain projects. Flat bars provide a versatile, smooth surface suitable for fabrication and welding, but they may lack the inherent rigidity of angle bars in load-bearing scenarios. Choosing between the two depends on Your project's load requirements and design flexibility.

Choosing the Right Bar for Your Project

Choosing the right bar for your project depends on the load-bearing requirements and the specific application. Angle bars provide excellent structural support and resistance to bending, making them ideal for frameworks and reinforcements, while flat bars offer versatility for general fabrication, brackets, and machining tasks. Consider the dimensions, material grade, and mechanical properties to ensure your choice aligns with your project's strength and durability needs.

Angle bar vs flat bar Infographic

libmatt.com

libmatt.com