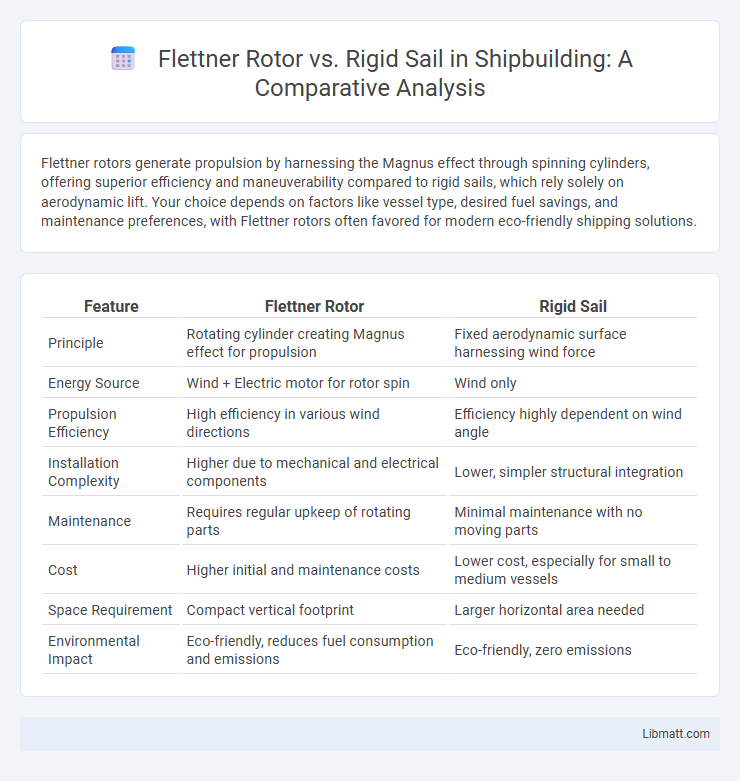

Flettner rotors generate propulsion by harnessing the Magnus effect through spinning cylinders, offering superior efficiency and maneuverability compared to rigid sails, which rely solely on aerodynamic lift. Your choice depends on factors like vessel type, desired fuel savings, and maintenance preferences, with Flettner rotors often favored for modern eco-friendly shipping solutions.

Table of Comparison

| Feature | Flettner Rotor | Rigid Sail |

|---|---|---|

| Principle | Rotating cylinder creating Magnus effect for propulsion | Fixed aerodynamic surface harnessing wind force |

| Energy Source | Wind + Electric motor for rotor spin | Wind only |

| Propulsion Efficiency | High efficiency in various wind directions | Efficiency highly dependent on wind angle |

| Installation Complexity | Higher due to mechanical and electrical components | Lower, simpler structural integration |

| Maintenance | Requires regular upkeep of rotating parts | Minimal maintenance with no moving parts |

| Cost | Higher initial and maintenance costs | Lower cost, especially for small to medium vessels |

| Space Requirement | Compact vertical footprint | Larger horizontal area needed |

| Environmental Impact | Eco-friendly, reduces fuel consumption and emissions | Eco-friendly, zero emissions |

Introduction to Wind-Assisted Marine Propulsion

Flettner rotors and rigid sails represent innovative approaches to wind-assisted marine propulsion, enhancing fuel efficiency and reducing emissions in maritime transport. Flettner rotors utilize spinning cylinders to generate lift through the Magnus effect, offering dynamic control and energy savings in diverse wind conditions. Your choice between these technologies depends on vessel type, operating profile, and environmental goals, with each system contributing significantly to greener shipping practices.

Understanding Flettner Rotors: Principles and Design

Flettner rotors utilize the Magnus effect by spinning cylindrical rotors vertically to generate lift from wind, providing propulsion with higher efficiency compared to traditional rigid sails. Their innovative design involves rotating cylinders powered mechanically, which interact with wind flow to create thrust perpendicular to wind direction, enhancing fuel savings and reducing carbon emissions. Understanding these principles helps you evaluate the performance advantages of Flettner rotors over rigid sails in modern maritime applications.

What Are Rigid Sails? Technology and Structure

Rigid sails are advanced aerodynamic structures made from lightweight composite materials, designed to maximize wind propulsion efficiency with minimal maintenance compared to traditional fabric sails. Unlike Flettner rotors that utilize spinning cylindrical surfaces to harness the Magnus effect, rigid sails operate through fixed or adjustable airfoil shapes that optimize lift and reduce drag during sailing. Their technology includes integrated control systems for angle adjustment, enhancing vessel maneuverability and fuel savings in commercial shipping.

Historical Development: Flettner Rotor and Rigid Sail Innovations

The Flettner rotor, developed by Anton Flettner in the 1920s, revolutionized wind propulsion by utilizing the Magnus effect through rotating cylinders to enhance ship propulsion efficiency. In contrast, rigid sails, evolving from traditional fabric sails, incorporate advanced composite materials and aerodynamic designs that enable superior durability and control. Both innovations mark significant milestones in maritime technology, with the Flettner rotor emphasizing mechanical rotation and the rigid sail focusing on structural strength and optimized airflow management.

Performance Comparison: Efficiency and Fuel Savings

Flettner rotors generate thrust by harnessing the Magnus effect, delivering up to 20-30% fuel savings on commercial vessels compared to traditional rigid sails, which rely primarily on aerodynamic lift with less effective force generation. Rigid sails offer simpler maintenance and consistent performance in variable winds but generally achieve lower fuel efficiency gains, typically around 10-15%. Fuel consumption reductions with Flettner rotors are more pronounced during steady, moderate wind conditions, making them highly effective for large cargo ships seeking significant operational cost reductions.

Installation and Operational Considerations

Flettner rotors require complex installation involving electrical systems and rotating mechanisms, demanding precise alignment and maintenance of bearings and motors. Rigid sails offer simpler installation with fixed mounting but need robust structural support to withstand wind loads and adjust for optimal aerodynamics. Operationally, Flettner rotors provide automated thrust control through variable rotation speeds, while rigid sails rely on manual or semi-automated angle adjustments to capture wind effectively.

Maintenance Requirements and Durability

Flettner rotors require regular maintenance due to their mechanical components, such as rotating cylinders and motors, which need lubrication and inspection to ensure optimal performance and prevent breakdowns. Rigid sails have higher durability with fewer moving parts, reducing maintenance frequency and associated costs, but they may require periodic inspections for wear and damage from harsh marine conditions. Your choice between these propulsion methods should consider the trade-off between the mechanical complexity of Flettner rotors and the structural robustness of rigid sails for long-term operational efficiency.

Cost Analysis: Investment and Return

Flettner rotors typically require higher initial investment costs due to advanced engineering and installation complexity compared to rigid sails, which are simpler and less expensive to install. However, Flettner rotors offer greater fuel savings and higher efficiency in wind-assisted propulsion, leading to quicker return on investment and reduced operational costs over time. Cost analysis shows that despite the upfront expense, Flettner rotors can provide superior long-term economic benefits in commercial shipping applications.

Environmental Impact and Emissions Reduction

Flettner rotors reduce emissions by harnessing the Magnus effect to generate additional propulsion with minimal fuel consumption, cutting greenhouse gas outputs significantly compared to conventional engines. Rigid sails also decrease environmental impact by capturing wind energy directly, lowering reliance on fossil fuels and reducing CO2 emissions by up to 30% during optimal sailing conditions. Both technologies contribute to greener shipping by enabling substantial reductions in sulfur oxides, nitrogen oxides, and particulate matter emissions, improving air quality in maritime transport.

Future Prospects: Hybrid Solutions and Industry Adoption

Flettner rotors and rigid sails represent cutting-edge advancements in maritime propulsion, with hybrid solutions combining these technologies gaining traction for enhanced fuel efficiency and reduced emissions. Industry adoption is accelerating as shipping companies seek sustainable alternatives to traditional fuel, integrating Flettner rotors' aerodynamic lift with the structural reliability of rigid sails. Your investment in hybrid propulsion systems can position your fleet at the forefront of green shipping innovation, meeting future regulatory standards and economic demands.

Flettner rotor vs rigid sail Infographic

libmatt.com

libmatt.com