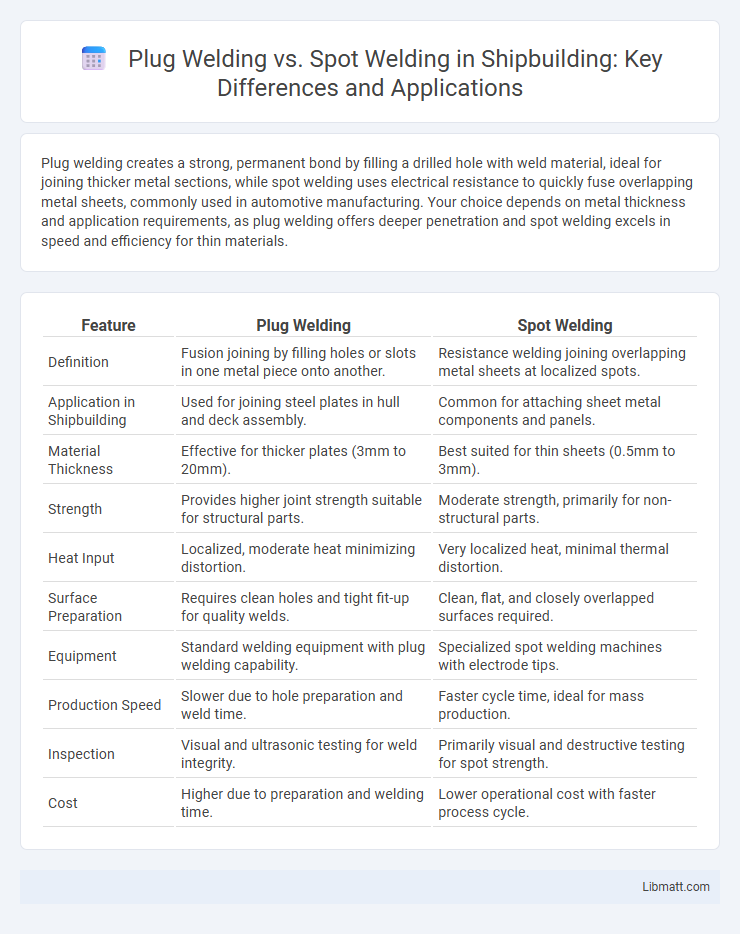

Plug welding creates a strong, permanent bond by filling a drilled hole with weld material, ideal for joining thicker metal sections, while spot welding uses electrical resistance to quickly fuse overlapping metal sheets, commonly used in automotive manufacturing. Your choice depends on metal thickness and application requirements, as plug welding offers deeper penetration and spot welding excels in speed and efficiency for thin materials.

Table of Comparison

| Feature | Plug Welding | Spot Welding |

|---|---|---|

| Definition | Fusion joining by filling holes or slots in one metal piece onto another. | Resistance welding joining overlapping metal sheets at localized spots. |

| Application in Shipbuilding | Used for joining steel plates in hull and deck assembly. | Common for attaching sheet metal components and panels. |

| Material Thickness | Effective for thicker plates (3mm to 20mm). | Best suited for thin sheets (0.5mm to 3mm). |

| Strength | Provides higher joint strength suitable for structural parts. | Moderate strength, primarily for non-structural parts. |

| Heat Input | Localized, moderate heat minimizing distortion. | Very localized heat, minimal thermal distortion. |

| Surface Preparation | Requires clean holes and tight fit-up for quality welds. | Clean, flat, and closely overlapped surfaces required. |

| Equipment | Standard welding equipment with plug welding capability. | Specialized spot welding machines with electrode tips. |

| Production Speed | Slower due to hole preparation and weld time. | Faster cycle time, ideal for mass production. |

| Inspection | Visual and ultrasonic testing for weld integrity. | Primarily visual and destructive testing for spot strength. |

| Cost | Higher due to preparation and welding time. | Lower operational cost with faster process cycle. |

Introduction to Plug Welding and Spot Welding

Plug welding involves filling a hole in one metal piece with weld material to join it to another underlying piece, creating a strong, continuous bond. Spot welding uses electrical resistance to fuse overlapping metal surfaces at discrete points, commonly applied in sheet metal fabrication. Both techniques are essential in automotive and manufacturing industries for efficient, reliable metal joining.

Key Differences Between Plug Welding and Spot Welding

Plug welding involves filling a hole in one metal piece with weld metal to join it to another piece underneath, creating a strong, continuous bond ideal for overlapping surfaces. Spot welding uses electrical resistance to fuse small, localized areas between two metal sheets, forming discrete weld spots commonly used in automotive manufacturing for rapid, high-strength joins. The primary differences lie in plug welding's use of filler material for a solid weld and spot welding's reliance on heat generated by resistance without filler, affecting the joint strength and application versatility.

Advantages of Plug Welding

Plug welding offers superior joint strength by filling holes in one metal piece with molten weld to fuse it to the underlying metal, creating a continuous bond that enhances load distribution. This method is advantageous for joining overlapping sheets or repairing holes without access to both sides of the workpiece, making it suitable for complex assemblies. Your projects benefit from improved corrosion resistance and cleaner weld appearance compared to spot welding, reducing the need for extensive surface finishing.

Advantages of Spot Welding

Spot welding offers advantages such as faster production speeds and lower heat input, reducing distortion in metal sheets. It provides strong, localized welds ideal for thin materials, improving overall structural integrity without the need for access to both sides of the workpieces. This method is highly efficient for automated assembly lines in automotive and manufacturing industries.

Common Applications for Plug Welding

Plug welding is commonly used in automotive manufacturing and structural steel fabrication, where joining overlapping metal sheets is essential for strength and durability. This method provides a solid, sealed connection ideal for repairing vehicle bodies and assembling heavy machinery. Your projects benefit from plug welding when securing components that require resistance to vibration and shear forces.

Typical Uses for Spot Welding

Spot welding is commonly used in automotive manufacturing for joining sheet metal parts due to its speed and efficiency. It is ideal for assembling thin metal components in appliances, electronics, and metal furniture where strong, localized bonds are required. This technique excels in mass production settings, promoting high throughput while maintaining consistent weld quality.

Strength and Durability Comparison

Plug welding provides superior strength and durability by creating a solid bond through the entire thickness of metal pieces, making it ideal for structural applications requiring high load resistance. Spot welding, while quicker and efficient for joining thin sheets, offers less strength due to its limited weld area concentrated at discrete points. For projects demanding maximum durability and long-term performance, your choice should prioritize plug welding over spot welding.

Equipment and Setup Requirements

Plug welding requires a drill or punch tool to create holes in one metal piece, and a MIG or TIG welder to fill the plugs, with moderate preparation time for alignment and hole placement. Spot welding necessitates specialized resistance welding machines with copper electrodes positioned on both sides of the workpieces, offering rapid setup but requiring precise electrode maintenance and pressure calibration. The equipment for spot welding generally demands a higher initial investment compared to plug welding tools, making spot welding more suited for high-volume manufacturing environments.

Cost Considerations: Plug vs Spot Welding

Plug welding generally incurs higher labor costs due to the additional preparation and precision required to create holes in the base material, whereas spot welding offers faster processing with lower labor expenses, making it more cost-effective for high-volume production. Material costs for plug welding can be higher as the process may require thicker base metals and additional filler material, while spot welding uses minimal consumables, primarily electrode tips and power. Equipment investment also differs: spot welding machines tend to be more affordable and easier to automate compared to the specialized tools required for plug welding, impacting overall project budgeting.

Choosing the Right Welding Method

Choosing the right welding method depends on the specific application, with plug welding offering advantages in joining overlapping materials where surface access is limited, especially in automotive and sheet metal fabrication. Spot welding excels in high-speed production environments, providing strong, consistent welds by fusing metals at discrete points and is ideal for thin metal sheets. Factors such as material thickness, joint configuration, and desired weld strength play critical roles in determining whether plug welding or spot welding is the optimal choice.

Plug welding vs spot welding Infographic

libmatt.com

libmatt.com