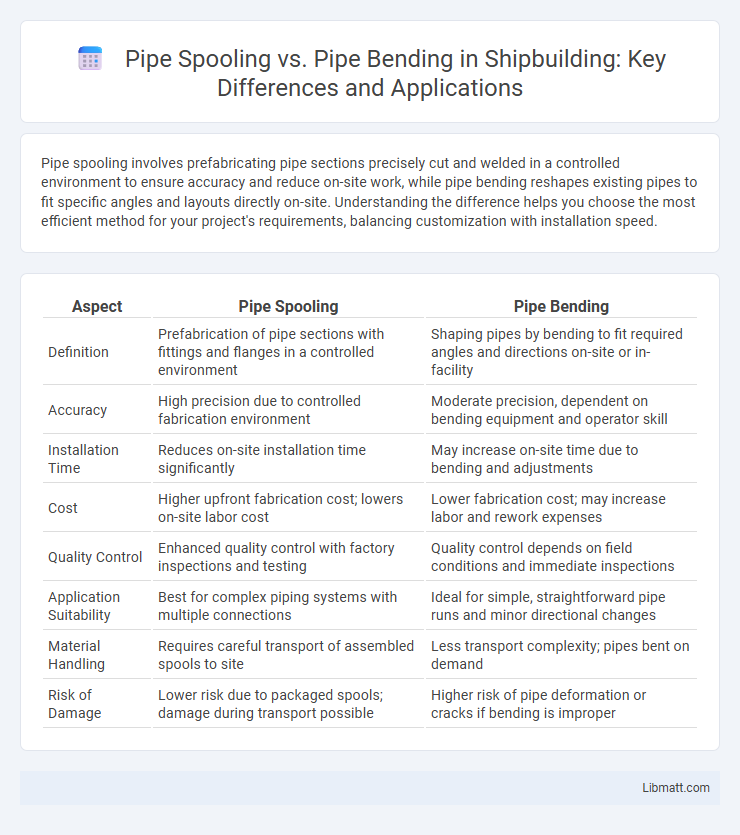

Pipe spooling involves prefabricating pipe sections precisely cut and welded in a controlled environment to ensure accuracy and reduce on-site work, while pipe bending reshapes existing pipes to fit specific angles and layouts directly on-site. Understanding the difference helps you choose the most efficient method for your project's requirements, balancing customization with installation speed.

Table of Comparison

| Aspect | Pipe Spooling | Pipe Bending |

|---|---|---|

| Definition | Prefabrication of pipe sections with fittings and flanges in a controlled environment | Shaping pipes by bending to fit required angles and directions on-site or in-facility |

| Accuracy | High precision due to controlled fabrication environment | Moderate precision, dependent on bending equipment and operator skill |

| Installation Time | Reduces on-site installation time significantly | May increase on-site time due to bending and adjustments |

| Cost | Higher upfront fabrication cost; lowers on-site labor cost | Lower fabrication cost; may increase labor and rework expenses |

| Quality Control | Enhanced quality control with factory inspections and testing | Quality control depends on field conditions and immediate inspections |

| Application Suitability | Best for complex piping systems with multiple connections | Ideal for simple, straightforward pipe runs and minor directional changes |

| Material Handling | Requires careful transport of assembled spools to site | Less transport complexity; pipes bent on demand |

| Risk of Damage | Lower risk due to packaged spools; damage during transport possible | Higher risk of pipe deformation or cracks if bending is improper |

Introduction to Pipe Spooling and Pipe Bending

Pipe spooling involves pre-fabricating pipe sections in a controlled environment to streamline on-site assembly, enhancing accuracy and reducing installation time. Pipe bending shapes pipes into desired angles without cutting, maintaining pipe integrity for fluid flow and structural strength. Understanding these processes helps you select the right technique for efficient piping system construction based on project requirements.

Definition and Core Concepts

Pipe spooling involves prefabricating pipe assemblies with components like flanges, fittings, and valves in a controlled workshop environment before installation. Pipe bending refers to the process of shaping pipes into specific angles or curves on-site to accommodate design requirements without breaking the pipe's integrity. Both techniques aim to optimize pipeline installation but differ in execution, with spooling emphasizing pre-assembly and bending focusing on in-field shaping.

Key Differences Between Pipe Spooling and Pipe Bending

Pipe spooling involves fabricating prefabricated pipe sections in a controlled workshop setting before installation, allowing for precise measurement and reduced on-site labor. Pipe bending, by contrast, reshapes existing pipes to fit specific angles and spatial constraints directly on-site or in manufacturing, which is essential for complex routing in piping systems. Key differences include spooling's emphasis on assembly and modularization versus bending's focus on altering pipe geometry without cutting or welding.

Advantages of Pipe Spooling

Pipe spooling offers precise, factory-controlled fabrication that ensures high accuracy and quality, reducing on-site installation time and labor costs. It minimizes the risk of material damage and welding errors by completing welds in a controlled environment, leading to improved safety and reliability. This method enhances project efficiency by allowing parallel workflow between spool fabrication and site preparation, accelerating overall project timelines.

Advantages of Pipe Bending

Pipe bending offers advantages such as maintaining the pipe's structural integrity by reducing the need for welds, which lowers the risk of leaks and failures. It allows for smoother flow within the pipeline by minimizing turbulence and pressure drops compared to spooled joints. Furthermore, pipe bending enhances installation efficiency by creating precise, custom angles that reduce the number of fittings and overall material costs.

Factors Influencing Method Selection

Factors influencing the selection between pipe spooling and pipe bending include project complexity, precision requirements, and installation environment. Pipe spooling offers enhanced accuracy for complex piping systems with multiple welds, while pipe bending excels in minimizing joints and reducing installation time in straightforward layouts. Your choice depends on balancing fabrication costs, on-site labor constraints, and the need for tight radius bends or intricate piping configurations.

Applications in Industrial Sectors

Pipe spooling is essential for modular construction in oil and gas, petrochemical plants, and power generation, allowing prefabricated pipe sections to be assembled offsite for efficient installation. Pipe bending is widely used in manufacturing, automotive, and HVAC industries to create complex shapes and custom curves that fit in confined spaces and optimize fluid flow. Both techniques enhance operational efficiency and safety by ensuring precise alignment and reducing field welding and leak risks.

Cost and Time Considerations

Pipe spooling significantly reduces on-site installation time by allowing prefabrication in controlled environments, decreasing labor costs and minimizing delays related to weather or site conditions. Pipe bending, while flexible and adaptable for complex layouts, often requires more on-site labor and can increase overall project time and expenses due to precision handling and potential material waste. Choosing between pipe spooling and bending should consider project scale, complexity, and the balance between upfront fabrication costs and on-site labor efficiency.

Quality Control and Safety Aspects

Pipe spooling ensures precise fabrication with controlled welding and assembly in a factory setting, enhancing quality control by reducing on-site errors and ensuring consistent joint integrity. Pipe bending, often performed on-site, allows for flexibility in installation but carries higher risks of material deformation and structural weaknesses if not executed with strict quality checks. Both methods require rigorous inspection protocols and adherence to safety standards to prevent leaks, failures, and ensure operator safety during handling and installation.

Future Trends in Pipe Fabrication Techniques

Future trends in pipe fabrication techniques emphasize automation and digital integration, with pipe spooling gaining momentum due to its precision and efficiency in pre-assembling complex pipeline sections off-site. Advanced robotics and 3D modeling streamline spooling processes, reducing material waste and fabrication time compared to traditional pipe bending methods. Your projects will benefit from these innovations through enhanced accuracy, faster turnaround, and optimized resource management in pipeline construction.

Pipe spooling vs pipe bending Infographic

libmatt.com

libmatt.com