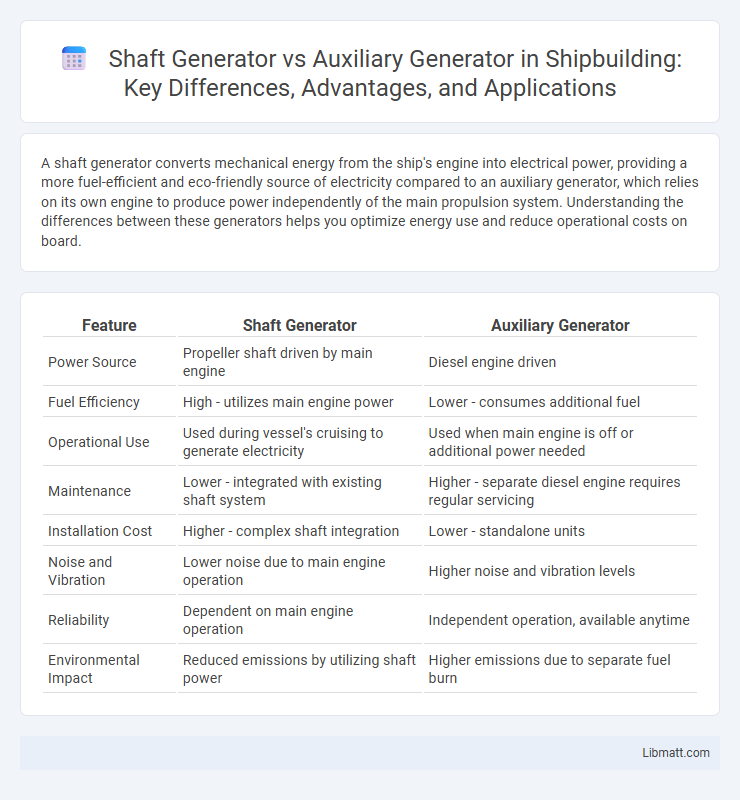

A shaft generator converts mechanical energy from the ship's engine into electrical power, providing a more fuel-efficient and eco-friendly source of electricity compared to an auxiliary generator, which relies on its own engine to produce power independently of the main propulsion system. Understanding the differences between these generators helps you optimize energy use and reduce operational costs on board.

Table of Comparison

| Feature | Shaft Generator | Auxiliary Generator |

|---|---|---|

| Power Source | Propeller shaft driven by main engine | Diesel engine driven |

| Fuel Efficiency | High - utilizes main engine power | Lower - consumes additional fuel |

| Operational Use | Used during vessel's cruising to generate electricity | Used when main engine is off or additional power needed |

| Maintenance | Lower - integrated with existing shaft system | Higher - separate diesel engine requires regular servicing |

| Installation Cost | Higher - complex shaft integration | Lower - standalone units |

| Noise and Vibration | Lower noise due to main engine operation | Higher noise and vibration levels |

| Reliability | Dependent on main engine operation | Independent operation, available anytime |

| Environmental Impact | Reduced emissions by utilizing shaft power | Higher emissions due to separate fuel burn |

Introduction to Shaft Generators and Auxiliary Generators

Shaft generators convert mechanical energy from a ship's main engine into electrical power, providing an efficient energy source during vessel operation and reducing fuel consumption. Auxiliary generators, powered by separate engines, supply electrical power when the main engine is off or during peak load conditions, ensuring continuous electricity availability. Understanding the roles of both shaft and auxiliary generators is essential for optimizing your ship's power management and overall fuel efficiency.

Core Functionality and Operation

Shaft generators convert mechanical energy from the ship's engine shaft into electrical energy, providing continuous power during propulsion without consuming additional fuel. Auxiliary generators operate independently from the main engine, supplying electrical power when the shaft generator is offline or during low-speed maneuvers. Both systems are essential for maintaining stable onboard electrical supply, with shaft generators optimized for efficiency during cruising and auxiliary generators ensuring backup and load management.

Key Differences Between Shaft and Auxiliary Generators

Shaft generators are directly coupled to the ship's main engine and produce electrical power when the vessel is underway, making them highly efficient for continuous energy supply during cruising. Auxiliary generators operate independently of the main engine and are primarily used when the ship is docked or during low-speed operations to provide essential power for onboard systems. Your choice between these generators depends on operational needs, fuel efficiency priorities, and the specific power demands of the vessel.

Efficiency and Fuel Consumption Comparison

Shaft generators directly convert mechanical energy from a ship's main engine into electrical power, offering higher efficiency and lower fuel consumption compared to auxiliary generators that rely on separate diesel engines. Auxiliary generators, while flexible for variable load demands, typically consume more fuel per kilowatt-hour due to less efficient engine operation and additional maintenance requirements. Choosing shaft generators reduces overall fuel costs and emissions by utilizing existing propulsion power, making them ideal for continuous electrical loads during cruising.

Installation and Space Requirements

Shaft generators are integrated directly with the ship's main engine shaft, requiring less dedicated space since they utilize existing mechanical power, making installation more compact and efficient. In contrast, auxiliary generators are standalone units that demand additional space for separate mounting, fuel supply, and ventilation systems. Your choice between the two depends on available engine room space and the need to optimize vessel design for power generation.

Maintenance and Operational Costs

Shaft generators typically incur lower operational costs as they utilize the main engine's power, reducing fuel consumption compared to auxiliary generators that rely on separate engines. Maintenance expenses for shaft generators are generally more predictable and limited to electrical and mechanical components, while auxiliary generators require regular engine servicing, fuel management, and frequent inspections. Your choice between the two can significantly impact long-term maintenance budgets and operational efficiency, especially in vessels with varying power demands.

Environmental Impact and Emissions

Shaft generators produce electricity by harnessing the ship's main engine power, resulting in lower fuel consumption and reduced greenhouse gas emissions compared to auxiliary generators, which rely on separate engines running on fuel. Auxiliary generators typically emit higher levels of nitrogen oxides (NOx) and particulate matter due to less efficient combustion processes. Optimizing your energy use by favoring shaft generators can significantly reduce your vessel's environmental footprint and compliance costs related to emissions regulations.

Application Scenarios in Maritime Vessels

Shaft generators operate by converting the mechanical energy from a ship's main engine into electrical power, making them ideal for large vessels with continuous engine operation such as container ships and cruise liners. Auxiliary generators provide electrical power independently of the main engine, commonly used during port stays, engine maintenance, or when the main engine is off, ensuring reliable power for essential systems on fishing boats, small cargo ships, and offshore supply vessels. The choice between shaft and auxiliary generators depends largely on the vessel's operational profile, fuel efficiency goals, and power demand variability.

Pros and Cons of Shaft vs Auxiliary Generators

Shaft generators offer high efficiency by utilizing the main engine's power to produce electricity, reducing fuel consumption and emissions, but they depend on engine operation and are costly to install and maintain. Auxiliary generators provide flexible power supply independent of the main engine, ensuring electricity during engine off periods or maintenance, though they consume additional fuel and generate noise and emissions. Selecting between shaft and auxiliary generators requires balancing operational efficiency against flexibility and cost considerations for marine or industrial applications.

Future Trends in Marine Power Generation Systems

Future trends in marine power generation systems emphasize the integration of shaft generators to enhance fuel efficiency by converting mechanical energy from the main engine into electrical power, reducing reliance on auxiliary generators. Innovations in hybrid systems increasingly combine shaft and auxiliary generators with energy storage solutions to optimize load management and lower emissions in compliance with IMO regulations. Advancements in smart control technologies and predictive maintenance drive improved performance and sustainability, positioning shaft generators as key components in next-generation marine propulsion architectures.

Shaft generator vs auxiliary generator Infographic

libmatt.com

libmatt.com