Sheer strake is the uppermost plank of a ship's hull, providing structural strength and affecting the vessel's appearance, while the garboard strake is the first plank laid next to the keel, crucial for waterproofing and hull integrity. Your choice between these planks depends on whether you prioritize top-edge strength or foundational hull sealing.

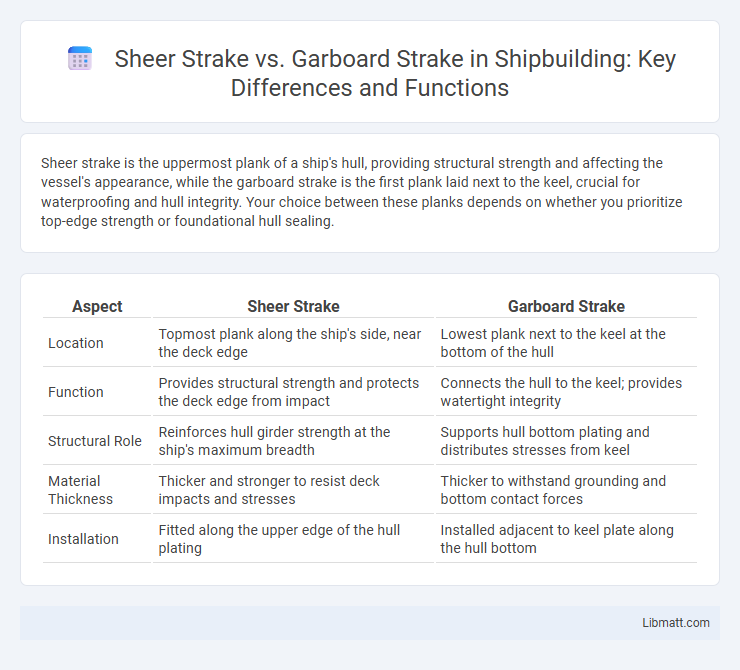

Table of Comparison

| Aspect | Sheer Strake | Garboard Strake |

|---|---|---|

| Location | Topmost plank along the ship's side, near the deck edge | Lowest plank next to the keel at the bottom of the hull |

| Function | Provides structural strength and protects the deck edge from impact | Connects the hull to the keel; provides watertight integrity |

| Structural Role | Reinforces hull girder strength at the ship's maximum breadth | Supports hull bottom plating and distributes stresses from keel |

| Material Thickness | Thicker and stronger to resist deck impacts and stresses | Thicker to withstand grounding and bottom contact forces |

| Installation | Fitted along the upper edge of the hull plating | Installed adjacent to keel plate along the hull bottom |

Introduction to Sheer Strake and Garboard Strake

The sheer strake is the uppermost plank or plate along the side of a ship's hull, running just below the deck edge and providing structural strength and aesthetic finish. The garboard strake is the first plank or plate fastened to the keel, forming the transition between the keel and the hull and bearing significant stress during construction and operation. Both strakes are essential for hull integrity, with the sheer strake contributing to longitudinal strength and the garboard strake ensuring a watertight connection at the vessel's bottom.

Definitions: Sheer Strake Explained

The sheer strake is the uppermost plank of a ship's hull, running along the deck edge to provide structural integrity and contribute to the vessel's appearance. The garboard strake is the first plank adjacent to the keel, crucial for strength and watertightness along the hull bottom. Understanding the role of the sheer strake helps you appreciate its importance in maintaining hull shape and resisting torsional stresses during navigation.

Understanding the Garboard Strake

The garboard strake is the first plank fastened to the keel, forming a critical watertight seal and providing structural integrity to the hull. Unlike the sheer strake, which runs along the top edge of the hull to reinforce the deck line and improve aesthetics, the garboard strake directly manages water resistance and hull strength at the bottom. Your vessel's durability and performance often depend on the proper maintenance and installation of the garboard strake.

Key Differences Between Sheer Strake and Garboard Strake

The shear strake is the topmost plank on a vessel's hull, providing structural support and contributing to the vessel's overall strength and aesthetic finish, while the garboard strake is the bottom plank adjacent to the keel, crucial for water-tight integrity and resistance to impact damage. Material thickness of the garboard strake is typically greater than the sheer strake to withstand stresses near the keel, and the sheer strake often has additional reinforcement to maintain hull shape at the shear line. Understanding these differences helps you assess hull maintenance and repair priorities effectively.

Functional Roles in Shipbuilding

Sheer strakes serve as the uppermost continuous plank or plating line along the ship's hull, providing structural strength and defining the vessel's sheer line for improved seaworthiness and aesthetic appeal. Garboard strakes are the first strakes adjacent to the keel, crucial for ensuring watertight integrity and supporting the keel's load-bearing role during construction and sailing. Both strakes contribute to hull durability but differ functionally: shear strakes enhance overall hull form and resistance to wave impacts, while garboard strakes focus on foundational stability and hydrodynamic efficiency near the waterline.

Importance of Placement on the Hull

The placement of the sheer strake versus the garboard strake plays a critical role in the structural integrity and hydrodynamic performance of the hull. The sheer strake, located at the upper edge of the hull, enhances the overall strength of the hull deck joint and helps resist torsional stresses, while the garboard strake, positioned closest to the keel, provides a crucial watertight seal and ensures proper load transfer from the hull to the keel. Precise positioning of these strakes is essential to optimize hull durability, stability, and resistance to hull deformation under varying sea conditions.

Material Selection: Sheer vs Garboard Strake

Sheer strakes and garboard strakes require distinct material selections due to their different locations and stress exposures on a vessel. Sheer strakes, positioned at the sheer line, benefit from materials with high resistance to bending and impact, such as marine-grade aluminum or stainless steel, to withstand wave impacts and deck loads. Garboard strakes, located near the keel, demand materials with superior corrosion resistance and toughness like high-strength steel or treated composites to endure constant water pressure and hull flexing, ensuring your vessel's structural integrity.

Structural Integrity and Design Implications

Sheer strakes provide enhanced structural integrity along the upper edges of a vessel, offering increased resistance to bending stresses and improving overall hull rigidity. Garboard strakes, positioned adjacent to the keel, are critical for the hull's longitudinal strength and form the primary barrier against bottom impacts and grounding forces. Your choice between sheer and garboard strakes influences hull design by balancing protective reinforcement with weight distribution, affecting both durability and performance in marine environments.

Common Construction Techniques

Sheer strakes are typically constructed as the uppermost planking or plating on a vessel's hull, often using thicker, more durable materials to withstand rough sea conditions and provide structural integrity near the deck edge. Garboard strakes are the first planks or plates laid immediately adjacent to the keel, requiring precise shaping and tight fastening to ensure watertightness and hull strength at this critical junction. Common construction techniques involve careful beveling and caulking for wooden boats, or welding and plating thickness optimization for steel hulls, ensuring a seamless connection between the sheer strake and garboard strake and maintaining overall vessel integrity.

Conclusion: Sheer Strake vs Garboard Strake in Modern Ship Design

The sheer strake enhances hull strength and improves aesthetic flow along the upper side of a ship, whereas the garboard strake provides critical structural support at the keel, ensuring watertight integrity and resistance to grounding stresses. Modern ship design prioritizes the garboard strake for foundational durability while leveraging the sheer strake for optimized hull curvature and stability. Both strakes play complementary roles, with the garboard strake serving as the structural backbone and the sheer strake contributing to overall hull form and seaworthiness.

Sheer strake vs garboard strake Infographic

libmatt.com

libmatt.com