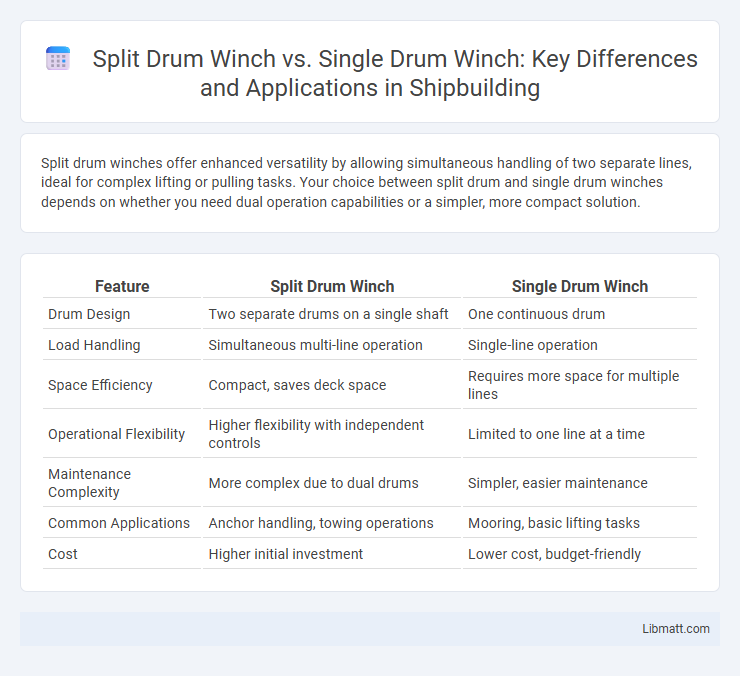

Split drum winches offer enhanced versatility by allowing simultaneous handling of two separate lines, ideal for complex lifting or pulling tasks. Your choice between split drum and single drum winches depends on whether you need dual operation capabilities or a simpler, more compact solution.

Table of Comparison

| Feature | Split Drum Winch | Single Drum Winch |

|---|---|---|

| Drum Design | Two separate drums on a single shaft | One continuous drum |

| Load Handling | Simultaneous multi-line operation | Single-line operation |

| Space Efficiency | Compact, saves deck space | Requires more space for multiple lines |

| Operational Flexibility | Higher flexibility with independent controls | Limited to one line at a time |

| Maintenance Complexity | More complex due to dual drums | Simpler, easier maintenance |

| Common Applications | Anchor handling, towing operations | Mooring, basic lifting tasks |

| Cost | Higher initial investment | Lower cost, budget-friendly |

Introduction to Split Drum and Single Drum Winches

Split drum winches feature two separate drums that allow simultaneous operation of different lines, enhancing efficiency for complex lifting or towing tasks. Single drum winches consist of one drum designed for straightforward pulling or lifting, ideal for simpler, singular load applications. Your choice depends on operational needs, with split drum winches offering versatility and single drum winches providing straightforward, robust performance.

How Split Drum Winches Work

Split drum winches operate by dividing the winch drum into two distinct sections, allowing simultaneous deployment or retrieval of two separate lines. This design enhances operational flexibility, enabling independent control and efficient load handling in complex lifting or towing applications. Split drum winches are commonly used in maritime, construction, and offshore industries where multipurpose line management is critical.

How Single Drum Winches Operate

Single drum winches operate by winding a cable or rope onto a single rotating drum to exert pulling force, enabling controlled lifting or towing. The drum's rotation is powered by electric, hydraulic, or pneumatic motors, and the cable is layered in a helical pattern to optimize space and strength. This design provides straightforward operation with consistent tension but may limit cable management flexibility compared to split drum winches.

Key Components of Both Winch Types

Split drum winches feature two separate drums allowing simultaneous operation with independent tension control, incorporating components like dual braking systems, separate gear trains, and multiple load sensors. Single drum winches consist of a single drum, a unified braking mechanism, one gearbox, and integrated load monitoring, suitable for straightforward hauling tasks. Both types utilize robust motor assemblies, cable guides, and control systems tailored to their specific operational requirements.

Advantages of Split Drum Winches

Split drum winches offer enhanced operational flexibility by allowing two separate line pulls or different line speeds from a single winch system. Their design enables simultaneous handling of multiple tasks, improving efficiency in complex lifting or towing operations. You benefit from reduced equipment weight and space requirements compared to using separate single drum winches.

Advantages of Single Drum Winches

Single drum winches offer a compact design that optimizes space on your vessel, making them ideal for tighter deck layouts. Their simplified mechanism requires less maintenance, resulting in lower operational costs and increased reliability. The focused pulling power of a single drum winch ensures efficient line handling and enhanced control during heavy-duty marine operations.

Common Applications for Split Drum Winches

Split drum winches excel in applications requiring multiple line pulls with different cable lengths, such as offshore drilling and marine operations where simultaneous load handling is critical. They are frequently used in industries like oil and gas, construction, and heavy lifting for tasks like anchor handling, towing, and lifting heavy equipment. Their design enables efficient line management, reducing downtime by allowing the operator to switch between drums quickly without rewinding cables.

Typical Uses for Single Drum Winches

Single drum winches are commonly used in towing, lifting, and anchoring applications due to their straightforward design and ease of operation. They excel in scenarios that require pulling or lifting heavy loads in a linear path, such as vehicle recovery, construction hoisting, and marine anchor handling. Their reliability and simplicity make them ideal for industries like construction, maritime, and transportation where consistent, powerful pulling force is essential.

Cost Comparison: Split Drum vs Single Drum Winch

Split drum winches generally have higher initial costs due to their complex design and dual-drum mechanism, making them more expensive than single drum winches. Single drum winches offer a more cost-effective solution with lower maintenance expenses, suitable for simpler lifting or pulling applications. The choice depends on budget constraints and operational requirements, where split drum winches justify their price with versatility and increased productivity.

Choosing the Right Winch for Your Needs

Split drum winches provide the advantage of using two different cable sizes or types simultaneously, making them ideal for versatile operations requiring quick cable changes without spooling. Single drum winches offer simplicity and durability, suited for straightforward lifting or pulling tasks with a single type of cable. Selecting the right winch depends on your operational needs, cable management preferences, and load capacity requirements, with split drum winches excelling in flexibility and single drum winches favored for reliability.

Split drum winch vs single drum winch Infographic

libmatt.com

libmatt.com