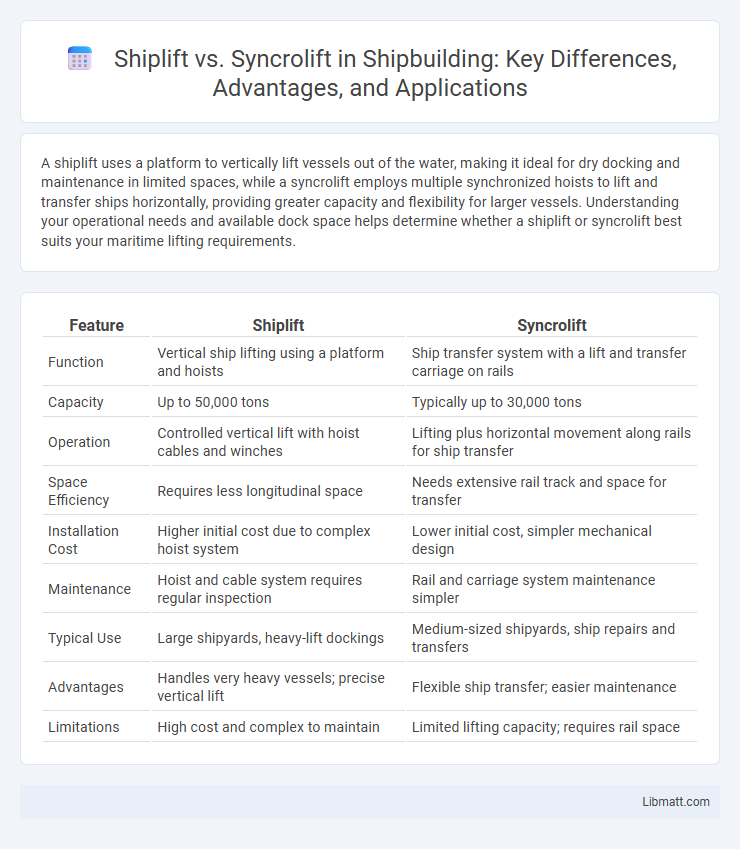

A shiplift uses a platform to vertically lift vessels out of the water, making it ideal for dry docking and maintenance in limited spaces, while a syncrolift employs multiple synchronized hoists to lift and transfer ships horizontally, providing greater capacity and flexibility for larger vessels. Understanding your operational needs and available dock space helps determine whether a shiplift or syncrolift best suits your maritime lifting requirements.

Table of Comparison

| Feature | Shiplift | Syncrolift |

|---|---|---|

| Function | Vertical ship lifting using a platform and hoists | Ship transfer system with a lift and transfer carriage on rails |

| Capacity | Up to 50,000 tons | Typically up to 30,000 tons |

| Operation | Controlled vertical lift with hoist cables and winches | Lifting plus horizontal movement along rails for ship transfer |

| Space Efficiency | Requires less longitudinal space | Needs extensive rail track and space for transfer |

| Installation Cost | Higher initial cost due to complex hoist system | Lower initial cost, simpler mechanical design |

| Maintenance | Hoist and cable system requires regular inspection | Rail and carriage system maintenance simpler |

| Typical Use | Large shipyards, heavy-lift dockings | Medium-sized shipyards, ship repairs and transfers |

| Advantages | Handles very heavy vessels; precise vertical lift | Flexible ship transfer; easier maintenance |

| Limitations | High cost and complex to maintain | Limited lifting capacity; requires rail space |

Introduction to Ship Handling Systems

Ship handling systems such as shiplifts and syncrolifts are essential for efficient vessel maintenance and repair by providing reliable means to lift ships out of water. Shiplifts use a platform with hoists that raise the vessel vertically, offering precise control and suitability for a range of ship sizes. Syncrolifts employ synchronized winches and a cradle system, enabling smooth vertical lifting and efficient dockyard throughput for rapid ship servicing.

What is a Shiplift?

A Shiplift is an advanced marine lifting system designed to vertically hoist vessels out of the water onto a stable platform for maintenance, repair, or storage. Unlike Syncrolift systems which use synchronized winches and a cradle moving along rails, Shiplifts utilize a robust platform supported by multiple hoisting units to evenly distribute weight, enabling efficient handling of various ship sizes. This technology enhances safety and turnaround time in shipyards by providing precise control and quick vessel transfer between water and dry dock areas.

What is a Syncrolift?

A Syncrolift is a specialized ship handling system designed to lift vessels from water onto a platform for repair, maintenance, or storage, utilizing synchronized hoists and a cradle system. It operates vertically, offering precise elevation while minimizing hull stress, making it ideal for large ships or dry docking in constrained spaces. You can rely on a Syncrolift for efficient, safe, and quick vessel transfer compared to traditional shiplift methods.

Key Differences Between Shiplift and Syncrolift

Shiplifts employ a platform hoist system to lift vessels vertically out of the water, primarily used for maintenance and repairs, whereas Syncrolifts utilize a synchronized winch mechanism to haul ships onto a transfer system for shore movement. The key difference lies in their operational method: Shiplifts lower and raise vessels directly in the water, while Syncrolifts combine vertical lift with horizontal transport capabilities. Syncrolifts often handle larger ship sizes and provide more flexibility in shipyard layouts compared to traditional shiplift systems.

Advantages of Using a Shiplift

Shiplifts offer precise vertical lifting capabilities, enabling safe and efficient handling of large vessels with minimal hull stress. Their modular design allows for customizable configurations that accommodate various ship sizes and weight capacities, enhancing operational flexibility. Rapid launch and retrieval processes reduce downtime, increasing overall shipyard productivity and turnaround times.

Benefits of the Syncrolift System

The Syncrolift system offers superior efficiency in ship launching and retrieval by utilizing a platform lift with synchronized hoists, enabling precise and simultaneous lifting of vessels. It reduces dockyard space requirements and minimizes turnaround time, which enhances operational productivity and cost-effectiveness. The system supports vessels of various sizes and weights, providing versatility unmatched by traditional shiplifts.

Applications and Use Cases

Shiplifts are ideal for small to medium-sized vessels, used primarily in shipyards and marinas for routine maintenance, repairs, and dry docking. Syncrolifts accommodate a wider range of vessel sizes and are often employed in large shipyards for lifting multiple ships simultaneously or handling very large ships efficiently. Both systems support shipbuilding, repair, and conversion projects, with syncrolifts offering enhanced flexibility in handling vessel weight and size variations.

Cost Comparison: Shiplift vs Syncrolift

Shiplifts generally offer a lower initial investment cost compared to Syncrolifts, making them more suitable for smaller shipyards or limited budgets. Syncrolifts involve higher upfront expenses due to their complex synchronized hoisting system but provide greater operational efficiency and faster lifting cycles. Maintenance costs tend to be higher for Syncrolifts because of the intricate machinery and electrical components, while Shiplifts require more manual labor but incur lower servicing charges.

Choosing the Right System for Your Shipyard

When selecting between Shiplift and Syncrolift systems for your shipyard, prioritize factors such as vessel size, lifting capacity, and operational efficiency. Shiplifts typically offer continuous transfer capabilities across multiple slipways, ideal for high-throughput shipyards. Syncrolifts provide vertical lifting with precise positioning, making them suitable for facilities requiring flexibility in dock layout and maintenance operations.

Future Trends in Ship Lifting Technology

Shiplifts are evolving with advancements in automation and predictive maintenance, enhancing operational efficiency and safety through IoT integration and AI-driven monitoring systems. Syncrolifts emphasize modular scalability and energy-efficient designs, promoting sustainability and reducing environmental impact in shipyard operations. Both technologies are increasingly adopting digital twins and smart sensors to optimize load distribution and maintenance scheduling, shaping the future of ship lifting with greater precision and reduced downtime.

Shiplift vs syncrolift Infographic

libmatt.com

libmatt.com