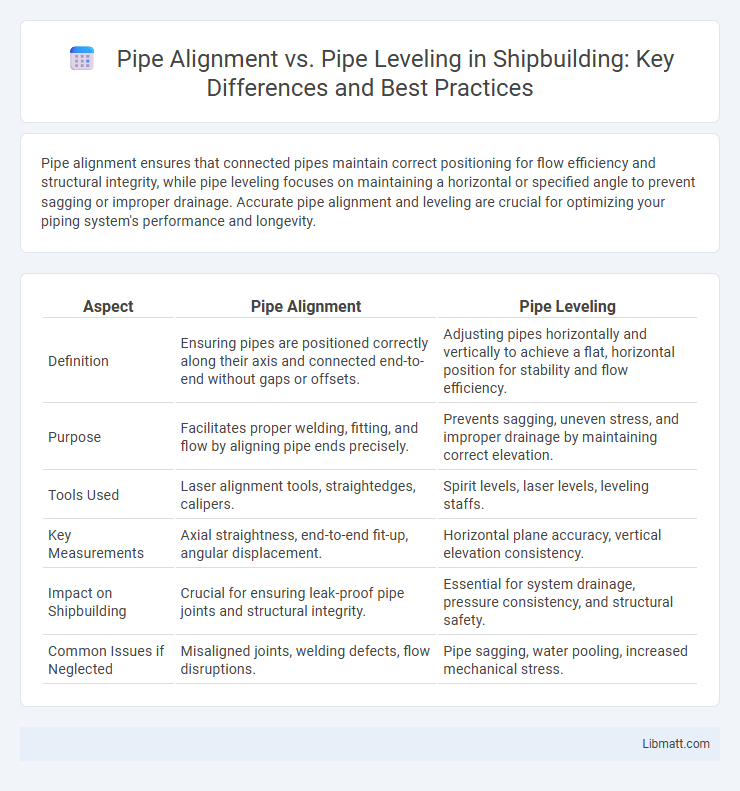

Pipe alignment ensures that connected pipes maintain correct positioning for flow efficiency and structural integrity, while pipe leveling focuses on maintaining a horizontal or specified angle to prevent sagging or improper drainage. Accurate pipe alignment and leveling are crucial for optimizing your piping system's performance and longevity.

Table of Comparison

| Aspect | Pipe Alignment | Pipe Leveling |

|---|---|---|

| Definition | Ensuring pipes are positioned correctly along their axis and connected end-to-end without gaps or offsets. | Adjusting pipes horizontally and vertically to achieve a flat, horizontal position for stability and flow efficiency. |

| Purpose | Facilitates proper welding, fitting, and flow by aligning pipe ends precisely. | Prevents sagging, uneven stress, and improper drainage by maintaining correct elevation. |

| Tools Used | Laser alignment tools, straightedges, calipers. | Spirit levels, laser levels, leveling staffs. |

| Key Measurements | Axial straightness, end-to-end fit-up, angular displacement. | Horizontal plane accuracy, vertical elevation consistency. |

| Impact on Shipbuilding | Crucial for ensuring leak-proof pipe joints and structural integrity. | Essential for system drainage, pressure consistency, and structural safety. |

| Common Issues if Neglected | Misaligned joints, welding defects, flow disruptions. | Pipe sagging, water pooling, increased mechanical stress. |

Introduction to Pipe Alignment and Pipe Leveling

Pipe alignment ensures that connected pipes fit together accurately, minimizing stress and preventing leaks or damage in piping systems. Pipe leveling focuses on establishing the correct horizontal position and slope, crucial for proper fluid flow and drainage. Understanding the difference between pipe alignment and pipe leveling helps you achieve efficient installation and long-term system reliability.

Importance of Proper Pipe Installation

Proper pipe installation is critical for ensuring system integrity, efficiency, and safety. Pipe alignment minimizes stress and potential leaks by ensuring sections connect accurately, while pipe leveling guarantees the correct slope for optimal fluid flow and drainage. Neglecting either aspect can lead to mechanical failures, increased maintenance costs, and compromised operational performance.

What is Pipe Alignment?

Pipe alignment ensures that connected piping components maintain proper positioning and orientation to avoid stresses and leaks during operation. It involves adjusting the pipes so their centerlines are in exact alignment, crucial for system integrity and efficient fluid flow. Your equipment's longevity and safety depend on precise pipe alignment rather than just pipe leveling, which only establishes a horizontal reference.

What is Pipe Leveling?

Pipe leveling is the precise process of measuring and adjusting the vertical position of a pipe to ensure it is perfectly horizontal or at a required slope, using tools such as spirit levels or laser levels. It is crucial in maintaining proper fluid flow and preventing issues like backflow, pooling, or improper drainage in piping systems. Unlike pipe alignment, which focuses on the correct positioning and direction of connected pipes, pipe leveling specifically addresses the elevation aspect for optimal system performance.

Key Differences Between Pipe Alignment and Pipe Leveling

Pipe alignment ensures that pipes are positioned correctly along the intended axis to maintain proper flow and avoid stress, while pipe leveling focuses on adjusting the pipe's horizontal or vertical angle to achieve a precise slope or elevation. Alignment addresses angular deviations and is critical in connecting multiple pipe sections seamlessly, whereas leveling primarily manages elevation differences to facilitate drainage or fluid flow. Both processes employ specialized tools, but alignment often requires laser alignment systems, and leveling uses spirit levels or digital inclinometers for accuracy.

Common Tools Used for Alignment and Leveling

Common tools used for pipe alignment include laser alignment devices, dial indicators, and spirit levels that ensure precise angular positioning and alignment of pipe sections. For pipe leveling, tools such as bubble levels, electronic digital levels, and inclinometer devices help verify and maintain correct pipe inclination and elevation. Your choice of equipment depends on the specific requirements for accuracy in both horizontal and vertical plane adjustments.

Challenges in Pipe Alignment and Leveling

Pipe alignment and leveling present significant challenges such as maintaining precise angular and elevation tolerances to ensure system integrity and prevent leaks or mechanical stress. Variations in thermal expansion, structural shifts, and uneven support conditions complicate achieving accurate alignment and leveling, often requiring specialized tools like laser alignment systems and precision leveling instruments. Inaccurate pipe alignment and leveling can lead to costly rework, premature equipment failure, and safety hazards in industrial piping systems.

Best Practices for Accurate Pipe Alignment

Accurate pipe alignment requires precise measurement tools such as laser alignment devices and dial indicators to ensure that pipe sections fit together without stress or misalignment. Best practices include maintaining consistent reference points, verifying levels regularly, and accounting for thermal expansion to prevent future operational issues. You can optimize your pipeline's longevity and performance by adhering to these detailed alignment protocols over simple pipe leveling methods.

Best Practices for Precise Pipe Leveling

Precise pipe leveling requires accurate measurement tools such as laser levels and spirit levels to ensure horizontal alignment, which prevents stress and potential failure in piping systems. Best practices include checking multiple points along the pipe run, adjusting supports incrementally, and verifying levelness after each adjustment to maintain consistent slope and prevent fluid drainage issues. Your attention to detail during pipe leveling improves system efficiency and longevity by avoiding misalignment-related leaks and mechanical wear.

Conclusion: Achieving Optimal Pipeline Performance

Proper pipe alignment ensures the correct angular positioning between pipeline sections, minimizing stress and preventing leaks, while accurate pipe leveling guarantees horizontal and vertical stability to maintain fluid flow efficiency. Combining precise alignment and leveling techniques reduces mechanical failures and enhances operational lifespan. Achieving optimal pipeline performance depends on integrating both processes to maintain structural integrity and maximize system reliability.

Pipe alignment vs pipe leveling Infographic

libmatt.com

libmatt.com