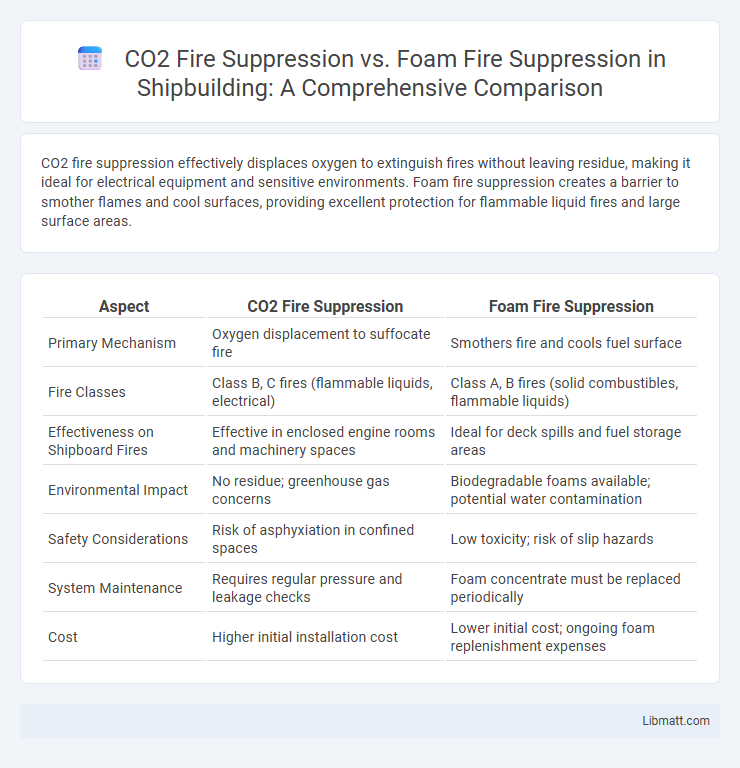

CO2 fire suppression effectively displaces oxygen to extinguish fires without leaving residue, making it ideal for electrical equipment and sensitive environments. Foam fire suppression creates a barrier to smother flames and cool surfaces, providing excellent protection for flammable liquid fires and large surface areas.

Table of Comparison

| Aspect | CO2 Fire Suppression | Foam Fire Suppression |

|---|---|---|

| Primary Mechanism | Oxygen displacement to suffocate fire | Smothers fire and cools fuel surface |

| Fire Classes | Class B, C fires (flammable liquids, electrical) | Class A, B fires (solid combustibles, flammable liquids) |

| Effectiveness on Shipboard Fires | Effective in enclosed engine rooms and machinery spaces | Ideal for deck spills and fuel storage areas |

| Environmental Impact | No residue; greenhouse gas concerns | Biodegradable foams available; potential water contamination |

| Safety Considerations | Risk of asphyxiation in confined spaces | Low toxicity; risk of slip hazards |

| System Maintenance | Requires regular pressure and leakage checks | Foam concentrate must be replaced periodically |

| Cost | Higher initial installation cost | Lower initial cost; ongoing foam replenishment expenses |

Understanding CO2 Fire Suppression Systems

CO2 fire suppression systems use carbon dioxide gas to quickly displace oxygen in the protected area, effectively extinguishing fires without leaving residue or damaging sensitive equipment. This method is ideal for environments such as server rooms, electrical cabinets, and industrial settings where water or foam might cause harm. Understanding how CO2 systems operate helps you ensure rapid fire control while preserving critical assets.

Overview of Foam Fire Suppression Systems

Foam fire suppression systems use a mixture of water, foam concentrate, and air to create a blanket that cools fire and isolates oxygen, effectively controlling flammable liquid and Class A fires. These systems are particularly effective in areas with high fuel loads, such as industrial sites and fuel storage tanks, due to their rapid fire knockdown and surface cooling capabilities. Your choice between CO2 and foam suppression should consider the fire class, environment safety, and the nature of the combustible materials involved.

How CO2 Extinguishes Fires

CO2 fire suppression extinguishes fires by displacing oxygen, which is essential for combustion, and lowering the temperature around the fire. The gas creates an inert atmosphere that suffocates the flames without leaving any residue, making it ideal for protecting sensitive electronic equipment and enclosed spaces. Unlike foam suppression, which forms a physical barrier on the fuel surface to prevent vapor release, CO2 suppresses fires through chemical asphyxiation and rapid cooling.

How Foam Suppression Works

Foam fire suppression works by creating a blanket of foam that smothers the fire, cutting off the oxygen supply and cooling the fuel. The foam also creates a barrier that prevents the release of flammable vapors, reducing the risk of reignition. This method is particularly effective on Class B fires involving flammable liquids and hydrocarbons.

Key Applications for CO2 Suppression

CO2 fire suppression is primarily used in environments with sensitive electronic equipment such as data centers, server rooms, and telecommunication facilities where residue-free extinguishing is crucial. It is highly effective for flammable liquid fires in industrial settings and machinery spaces, minimizing damage to valuable assets. Unlike foam systems, CO2 does not leave any cleanup residue, making it ideal for areas requiring rapid restoration post-incident.

Typical Uses of Foam Suppression

Foam fire suppression systems are typically used in environments where flammable liquids or hydrocarbons are present, such as in fuel storage tanks, aircraft hangars, and chemical plants. Foam extinguishes fires by creating a barrier between the fuel and oxygen, suppressing vapors, and cooling the fire surface, making it especially effective against Class B fires involving flammable liquids. This method provides rapid knockdown and longer-lasting protection compared to CO2 suppression, which is better suited for electrical fires and confined spaces.

Safety Considerations: CO2 vs Foam

CO2 fire suppression poses a higher risk to human safety due to its asphyxiation hazard in confined spaces, requiring strict evacuation protocols before discharge. Foam fire suppression systems offer improved safety by cooling flames and creating a barrier to prevent re-ignition, reducing toxic gas exposure. Your choice should factor in the environment and occupant presence to ensure optimal safety during fire emergencies.

Environmental Impact Comparison

CO2 fire suppression systems release carbon dioxide gas, which naturally dissipates without leaving residue but contributes to greenhouse gas emissions, impacting global warming. Foam fire suppression uses chemical agents that can introduce harmful compounds like PFAS into the environment, posing long-term contamination risks to water sources and soil. Your choice between CO2 and foam suppression should weigh the trade-offs between immediate environmental impact and potential long-term ecological damage.

Cost and Maintenance Differences

CO2 fire suppression systems typically incur lower initial installation costs compared to foam systems but require specialized ventilation and safety measures, increasing operational expenses. Foam fire suppression involves higher upfront costs due to chemical agents and application equipment, with ongoing expenses related to foam concentrate refills and environmental compliance. Maintenance for CO2 systems centers on cylinder inspections and leak detection, while foam systems demand regular testing of proportioning equipment and foam concentrate quality monitoring for effective performance.

Choosing the Right Fire Suppression System

Choosing the right fire suppression system depends on the specific hazards and environment of your space, with CO2 systems excelling in electrical and sensitive equipment areas by quickly displacing oxygen without leaving residue. Foam fire suppression is more effective for Class B fires involving flammable liquids, as it creates a barrier to prevent re-ignition and cools the fuel surface. Assessing the type of fire risk and equipment sensitivity helps ensure your system choice maximizes safety and minimizes damage.

CO2 fire suppression vs foam fire suppression Infographic

libmatt.com

libmatt.com