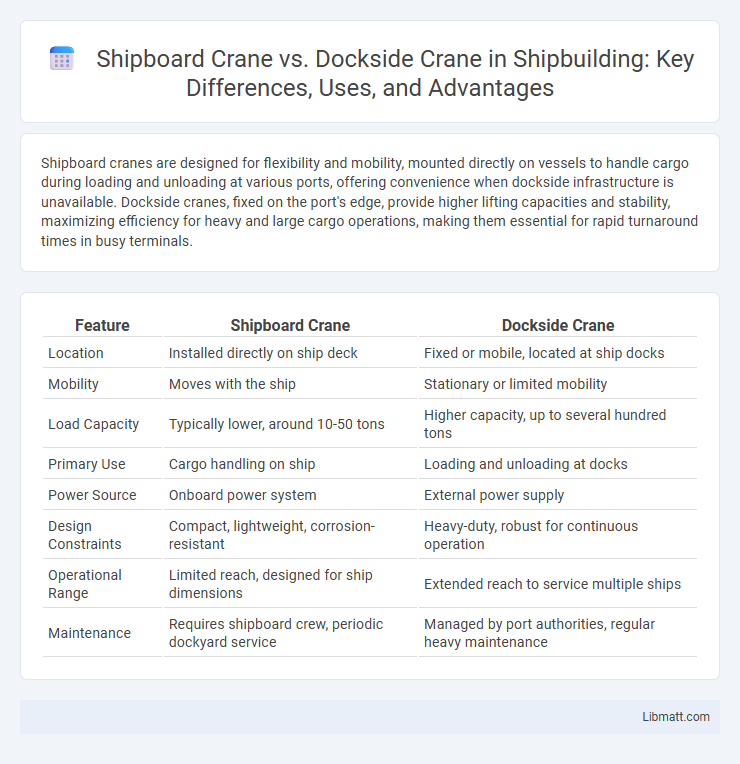

Shipboard cranes are designed for flexibility and mobility, mounted directly on vessels to handle cargo during loading and unloading at various ports, offering convenience when dockside infrastructure is unavailable. Dockside cranes, fixed on the port's edge, provide higher lifting capacities and stability, maximizing efficiency for heavy and large cargo operations, making them essential for rapid turnaround times in busy terminals.

Table of Comparison

| Feature | Shipboard Crane | Dockside Crane |

|---|---|---|

| Location | Installed directly on ship deck | Fixed or mobile, located at ship docks |

| Mobility | Moves with the ship | Stationary or limited mobility |

| Load Capacity | Typically lower, around 10-50 tons | Higher capacity, up to several hundred tons |

| Primary Use | Cargo handling on ship | Loading and unloading at docks |

| Power Source | Onboard power system | External power supply |

| Design Constraints | Compact, lightweight, corrosion-resistant | Heavy-duty, robust for continuous operation |

| Operational Range | Limited reach, designed for ship dimensions | Extended reach to service multiple ships |

| Maintenance | Requires shipboard crew, periodic dockyard service | Managed by port authorities, regular heavy maintenance |

Introduction to Shipboard and Dockside Cranes

Shipboard cranes are compact, specialized lifting devices mounted directly on vessels to facilitate cargo handling at sea or in port, designed to operate within the confined spaces of ships. Dockside cranes, on the other hand, are large, stationary or rail-mounted machines located on ports or docks, capable of handling heavier loads with greater reach and lifting height to transfer cargo efficiently between ships and shore. Your choice between shipboard and dockside cranes depends on factors such as space availability, load capacity requirements, and port infrastructure.

Key Differences Between Shipboard and Dockside Cranes

Shipboard cranes are designed for mobility and compactness, enabling efficient cargo handling directly on vessels, while dockside cranes are stationary structures optimized for heavy lifting and rapid loading or unloading at port terminals. Shipboard cranes have limited lifting capacity and reach compared to dockside cranes, which feature higher load capacities and extended operational ranges to accommodate large container ships. The operational environment also differs, with shipboard cranes engineered to withstand marine conditions and limited deck space, whereas dockside cranes are built to operate in more spacious, stable port settings.

Design and Structural Features

Shipboard cranes feature compact designs with robust, corrosion-resistant materials tailored for marine environments and limited deck space, incorporating slewing and telescoping booms for flexibility. Dockside cranes are larger, fixed or rail-mounted structures with high lifting capacities and extended reach designed for heavy-duty cargo handling directly on the dock. The structural foundation of dockside cranes emphasizes stability and load distribution, while shipboard cranes prioritize mobility and integration with ship operations.

Operational Environments

Shipboard cranes operate in dynamic maritime environments, mounted directly on vessels to facilitate cargo handling without reliance on port infrastructure, making them essential for at-sea transfer and remote unloading. Dockside cranes, positioned on fixed port terminals, function in stable, land-based conditions with access to comprehensive power and control systems, enabling rapid loading and unloading of containers from a wide variety of ships. The operational environment difference directly affects their design, mobility, load capacity, and maintenance requirements.

Load Capacity and Lifting Capabilities

Shipboard cranes typically have lower load capacities, ranging from 10 to 50 tons, designed for medium-lift tasks directly on vessels, while dockside cranes can handle significantly heavier loads, often exceeding 100 tons, suitable for large containers and bulk cargo. The lifting capabilities of shipboard cranes emphasize mobility and flexibility to operate in tight, moving environments, whereas dockside cranes prioritize high reach and stability to efficiently load and unload ships at ports. Your choice between the two should consider the specific requirements of cargo weight and operational environment to maximize efficiency and safety.

Installation and Mobility Considerations

Shipboard cranes are integrated directly onto the vessel, providing mobility that matches the ship's movements and requiring specialized installation to withstand marine conditions and dynamic loads. Dockside cranes are fixed installations on port quays, designed for high stability and heavy lifting capacity but lack the mobility of shipboard cranes, limiting them to specific locations. Your choice between these crane types depends on operational flexibility needs and the complexity of installation within the marine environment.

Safety Standards and Risk Management

Shipboard cranes are designed with stringent safety standards to operate safely in dynamic maritime environments, incorporating features like anti-collision systems and load monitoring to manage risks effectively. Dockside cranes follow rigorous regulatory requirements focused on stability and structural integrity due to their fixed positions, ensuring safe cargo handling amid high traffic. Your choice between these crane types should consider the specific safety protocols and risk management practices relevant to operational environments.

Maintenance and Longevity

Shipboard cranes require rigorous maintenance to withstand harsh marine environments, including regular corrosion control and lubrication to ensure longevity. Dockside cranes benefit from more accessible maintenance routines due to their fixed position, enabling quicker repairs and extended operational life. Your choice between the two should consider the maintenance demands and lifespan aligned with your operational needs and environmental exposure.

Cost Implications and Economic Factors

Shipboard cranes generally incur higher initial costs due to compact design requirements and specialized equipment needed for onboard installation, leading to increased maintenance expenses from constant exposure to marine environments. Dockside cranes, while costly in terms of infrastructure investment and land use, offer greater lifting capacity and operational efficiency, reducing per-unit handling costs in volume cargo operations. Economic considerations must weigh the trade-off between the mobility and flexibility of shipboard cranes versus the scalability and throughput advantages of dockside cranes in port logistics.

Choosing the Right Crane for Your Maritime Needs

Selecting the appropriate crane for maritime operations depends on operational context and load requirements; shipboard cranes are ideal for onboard cargo handling with compact designs and limited lifting capacity, while dockside cranes offer higher lifting capacities and reach for heavy containers and bulk cargo at ports. Consider factors such as load capacity, mobility, space constraints, and maintenance when choosing between shipboard and dockside cranes to enhance efficiency and safety. Evaluating the specific vessel type and port infrastructure ensures optimal crane performance tailored to your maritime logistics needs.

Shipboard crane vs dockside crane Infographic

libmatt.com

libmatt.com