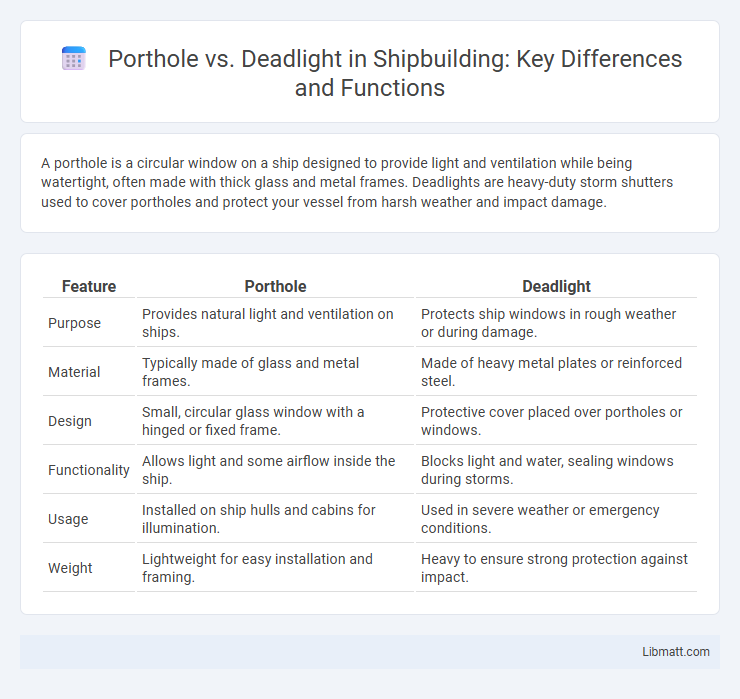

A porthole is a circular window on a ship designed to provide light and ventilation while being watertight, often made with thick glass and metal frames. Deadlights are heavy-duty storm shutters used to cover portholes and protect your vessel from harsh weather and impact damage.

Table of Comparison

| Feature | Porthole | Deadlight |

|---|---|---|

| Purpose | Provides natural light and ventilation on ships. | Protects ship windows in rough weather or during damage. |

| Material | Typically made of glass and metal frames. | Made of heavy metal plates or reinforced steel. |

| Design | Small, circular glass window with a hinged or fixed frame. | Protective cover placed over portholes or windows. |

| Functionality | Allows light and some airflow inside the ship. | Blocks light and water, sealing windows during storms. |

| Usage | Installed on ship hulls and cabins for illumination. | Used in severe weather or emergency conditions. |

| Weight | Lightweight for easy installation and framing. | Heavy to ensure strong protection against impact. |

Introduction to Portholes and Deadlights

Portholes are circular, watertight windows designed for illumination and ventilation on ships, commonly made of glass and metal frames. Deadlights are solid, protective covers made of metal or wood, used to shield ship windows during harsh weather or emergencies. Both serve crucial roles in maritime safety and structural integrity, with portholes emphasizing visibility and deadlights prioritizing protection.

Defining Porthole: Features and Functions

A porthole is a circular window commonly found on ships and boats, designed to provide natural light and ventilation while maintaining structural integrity against harsh marine conditions. Featuring thick glass and a watertight frame, portholes ensure safety by preventing water ingress during rough seas. Your vessel benefits from portholes by combining durability with visibility, allowing you to enjoy exterior views without compromising protection.

Understanding Deadlight: Purpose and Characteristics

Deadlights are sturdy metal covers installed over ship windows or portholes to protect against violent weather and structural damage. Unlike transparent portholes, deadlights provide a solid barrier, enhancing the vessel's safety during storms or rough seas. Their robust construction is essential for maintaining the hull's integrity while preventing water ingress.

Key Differences Between Porthole and Deadlight

Portholes are circular, glazed windows designed for natural light and visibility on ships, allowing crew to see outside while maintaining watertight integrity. Deadlights are solid, metal covers fitted over ship windows or portholes to provide extra protection against heavy seas and storms, preventing water ingress and damage. The primary distinction lies in functionality: portholes offer light and view, whereas deadlights serve as protective barriers during rough conditions.

Materials Used in Portholes vs. Deadlights

Portholes commonly utilize brass or bronze frames paired with toughened or laminated glass, designed to withstand marine environments and resist corrosion. Deadlights typically feature robust steel or aluminum frames with thick, sealed glass or solid metal covers, aimed at reinforcing the hull's structural integrity and providing watertight protection. The choice of materials reflects the distinct functional demands: portholes emphasize visibility and durability, whereas deadlights prioritize strength and security.

Advantages of Portholes

Portholes offer enhanced visibility and natural light, improving onboard ambiance and safety by allowing crew members to monitor external conditions. Their circular design provides superior resistance to pressure and water ingress, making them ideal for rough sea environments. Portholes are also easier to open and close for ventilation compared to deadlights, enhancing air circulation within the vessel.

Benefits of Deadlights

Deadlights provide superior protection against harsh weather conditions, ensuring watertight security on vessels during storms or rough seas. Their solid construction enhances structural integrity and prevents water ingress better than glass portholes. Additionally, deadlights require minimal maintenance and reduce the risk of damage or breakage in extreme marine environments.

Typical Applications on Vessels

Portholes are commonly installed on passenger ships, yachts, and cruise liners to provide natural light and ventilation while maintaining aesthetic appeal. Deadlights serve primarily as protective covers on commercial vessels, fishing boats, and cargo ships, designed to shield windows from harsh weather and sea impacts. You can choose portholes for comfort and style or deadlights for durability and safety in marine environments.

Maintenance and Durability Comparison

Portholes, typically made from brass or stainless steel with toughened glass, require regular cleaning and occasional resealing to prevent leaks and corrosion but offer long-term durability and ease of maintenance. Deadlights, constructed from heavy-duty steel frames with thick glass or acrylic, provide superior resistance to extreme weather and impact but demand more intensive upkeep to address rust and paint deterioration. Both designs balance durability with maintenance needs, where portholes favor ease of service and deadlights excel in robust protection under harsh maritime conditions.

Choosing the Right Option for Your Vessel

Selecting between a porthole and a deadlight depends on factors such as vessel type, location, and desired functionality; portholes offer visibility and ventilation, ideal for passenger areas, while deadlights provide enhanced security and weather protection, suitable for harsh conditions or off-duty windows. Consider the vessel's exposure to elements and interior lighting needs to ensure safety and comfort; portholes are often made from tempered glass or acrylic, whereas deadlights incorporate robust steel or aluminum covers for reinforcement. Maintenance requirements and compliance with maritime regulations also influence the decision, with portholes requiring more frequent cleaning and deadlights offering greater durability in rough seas.

Porthole vs deadlight Infographic

libmatt.com

libmatt.com