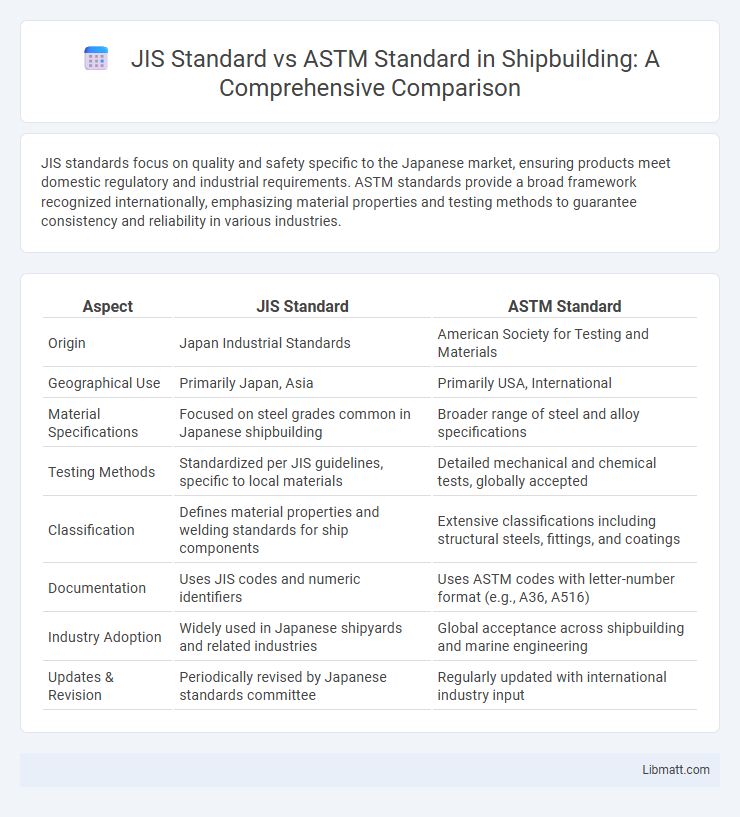

JIS standards focus on quality and safety specific to the Japanese market, ensuring products meet domestic regulatory and industrial requirements. ASTM standards provide a broad framework recognized internationally, emphasizing material properties and testing methods to guarantee consistency and reliability in various industries.

Table of Comparison

| Aspect | JIS Standard | ASTM Standard |

|---|---|---|

| Origin | Japan Industrial Standards | American Society for Testing and Materials |

| Geographical Use | Primarily Japan, Asia | Primarily USA, International |

| Material Specifications | Focused on steel grades common in Japanese shipbuilding | Broader range of steel and alloy specifications |

| Testing Methods | Standardized per JIS guidelines, specific to local materials | Detailed mechanical and chemical tests, globally accepted |

| Classification | Defines material properties and welding standards for ship components | Extensive classifications including structural steels, fittings, and coatings |

| Documentation | Uses JIS codes and numeric identifiers | Uses ASTM codes with letter-number format (e.g., A36, A516) |

| Industry Adoption | Widely used in Japanese shipyards and related industries | Global acceptance across shipbuilding and marine engineering |

| Updates & Revision | Periodically revised by Japanese standards committee | Regularly updated with international industry input |

Introduction to JIS and ASTM Standards

JIS (Japanese Industrial Standards) and ASTM (American Society for Testing and Materials) are globally recognized frameworks ensuring material and product quality across industries. JIS standards primarily cater to Japan's market and emphasize consistency in manufacturing processes, while ASTM standards provide detailed testing methods and are widely adopted in the U.S. and internationally for materials, products, systems, and services. Understanding these standards helps you evaluate product specifications effectively and ensures compliance with regional and international quality benchmarks.

Overview of JIS Standardization Process

The JIS (Japanese Industrial Standards) standardization process involves systematic development, review, and approval by the Japanese Industrial Standards Committee (JISC) to ensure consistency and quality across Japanese industries. Unlike ASTM standards, which are developed through consensus among international experts in specific technical fields, JIS focuses primarily on harmonizing domestic industrial practices with international frameworks while addressing Japan's unique market needs. Your understanding of JIS standards is crucial for compliance and product quality when engaging with Japanese manufacturers or markets.

Overview of ASTM Standardization Process

The ASTM standardization process involves the development of consensus-based technical standards through a global network of experts across various industries, emphasizing transparency, inclusiveness, and rigorous peer review. This process ensures that standards meet specific safety, quality, and performance requirements critical for product consistency and regulatory compliance. Your understanding of ASTM standards benefits from recognizing their dynamic revision system, which keeps standards current with technological advancements and market needs.

Key Differences Between JIS and ASTM Standards

JIS standards, developed by the Japanese Industrial Standards Committee, emphasize precision and harmonization with Japanese manufacturing practices, while ASTM standards, created by ASTM International, focus on a broad range of materials and testing methods widely adopted in North America. Key differences include regional applicability, specific measurement units (metric for JIS and imperial for ASTM), and variations in testing procedures and quality benchmarks tailored to respective industrial needs. Understanding these distinctions helps you select the most appropriate standard for compliance, ensuring optimal product performance and regulatory adherence.

Material Classification: JIS vs ASTM

JIS standards classify materials based on Japanese Industrial specifications, emphasizing chemical composition and mechanical properties tailored for local industries, with grades often linked to specific applications such as structural steel or stainless steel. ASTM standards, widely used internationally, categorize materials through detailed test methods and performance criteria, including tensile strength, hardness, and corrosion resistance, applying comprehensive codes like ASTM A36 for carbon steel and ASTM A240 for stainless steel grades. The primary distinction lies in JIS's regional specificity versus ASTM's broader global acceptance, influencing material selection depending on manufacturing and certification requirements.

Testing Methods Comparison: JIS vs ASTM

JIS (Japanese Industrial Standards) and ASTM (American Society for Testing and Materials) differ in testing methods across various materials and products, with JIS emphasizing more rigid procedural steps and ASTM offering broader method variations tailored to specific industries. ASTM methods are often globally accepted for their detailed, performance-based criteria, while JIS standards prioritize consistency in testing conditions to enhance reproducibility primarily within Japanese manufacturing contexts. Both standards cover similar mechanical and chemical tests but may vary in sample preparation, environmental conditions, and measurement techniques, impacting the comparability of test results internationally.

Industry Applications for JIS and ASTM

JIS standards are predominantly applied in manufacturing and automotive industries within Japan and other Asian markets, ensuring compatibility and quality in electronics, machinery, and construction materials. ASTM standards are widely adopted globally, especially in the United States, focusing on diverse sectors such as oil and gas, construction, metals, and consumer products, providing comprehensive test methods, specifications, and guidelines. Understanding the specific requirements of JIS or ASTM can help your business align with regional industry practices and regulatory compliance.

Interchangeability and Compatibility Issues

JIS (Japanese Industrial Standards) and ASTM (American Society for Testing and Materials) standards often differ in material specifications, dimensions, and testing methods, leading to interchangeability challenges when components from each standard are used together. Compatibility issues arise due to variations in mechanical properties, tolerances, and coating requirements, which can affect the performance and safety of assembled products. You should carefully evaluate these differences to ensure reliable integration of parts conforming to JIS and ASTM standards in your projects.

Advantages and Disadvantages of JIS and ASTM

JIS standards provide excellent compatibility with Japanese industrial processes, offering high precision and consistent quality in manufacturing, but may have limited global recognition outside Asia. ASTM standards boast widespread international acceptance and extensive testing protocols, enhancing global trade and safety compliance, yet their broad scope can sometimes lead to less specificity for particular regional needs. Both standards promote material reliability and performance, but selecting between them depends on target markets, industry requirements, and regional regulatory frameworks.

Choosing the Right Standard for Your Project

Selecting the JIS standard or ASTM standard depends on geographic location, industry requirements, and material specifications relevant to the project. JIS standards are predominantly used in Japan and emphasize compatibility with local materials and manufacturing processes, while ASTM standards are widely recognized in the United States and internationally, ensuring broad acceptance and rigorous testing methods. Evaluating project scope, compliance needs, and technical criteria ensures the appropriate standard supports quality assurance and regulatory adherence.

JIS standard vs ASTM standard Infographic

libmatt.com

libmatt.com