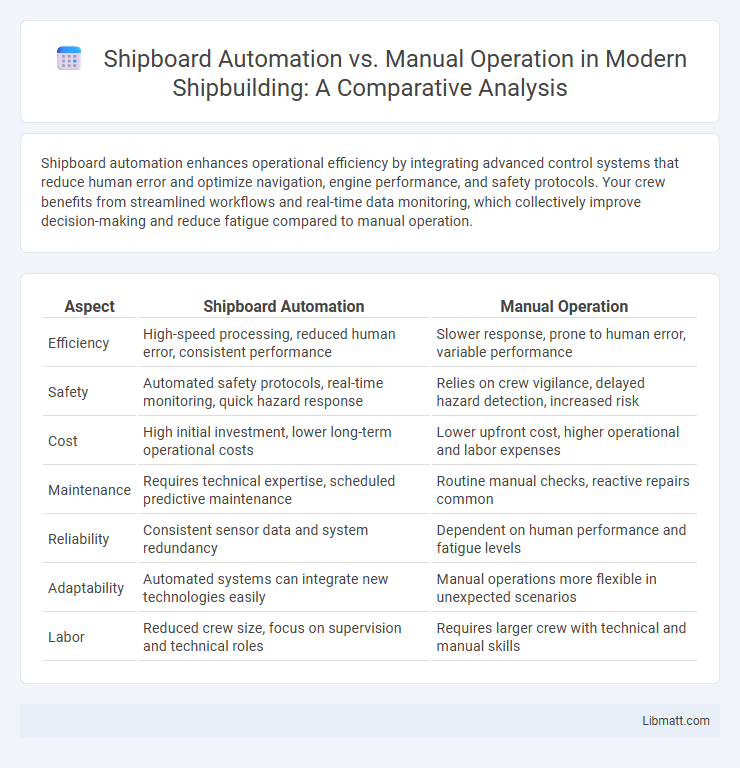

Shipboard automation enhances operational efficiency by integrating advanced control systems that reduce human error and optimize navigation, engine performance, and safety protocols. Your crew benefits from streamlined workflows and real-time data monitoring, which collectively improve decision-making and reduce fatigue compared to manual operation.

Table of Comparison

| Aspect | Shipboard Automation | Manual Operation |

|---|---|---|

| Efficiency | High-speed processing, reduced human error, consistent performance | Slower response, prone to human error, variable performance |

| Safety | Automated safety protocols, real-time monitoring, quick hazard response | Relies on crew vigilance, delayed hazard detection, increased risk |

| Cost | High initial investment, lower long-term operational costs | Lower upfront cost, higher operational and labor expenses |

| Maintenance | Requires technical expertise, scheduled predictive maintenance | Routine manual checks, reactive repairs common |

| Reliability | Consistent sensor data and system redundancy | Dependent on human performance and fatigue levels |

| Adaptability | Automated systems can integrate new technologies easily | Manual operations more flexible in unexpected scenarios |

| Labor | Reduced crew size, focus on supervision and technical roles | Requires larger crew with technical and manual skills |

Introduction to Shipboard Automation and Manual Operation

Shipboard automation integrates advanced control systems and sensors to manage navigation, engine performance, and safety functions, reducing human error and operational workload. In contrast, manual operation relies on crew members to perform all tasks, demanding continuous vigilance and hands-on control. The evolution from manual to automated systems enhances efficiency, accuracy, and real-time data processing aboard modern vessels.

Historical Evolution of Ship Operations

The historical evolution of ship operations shows a clear transition from manual control to sophisticated shipboard automation systems, driven by advances in technology and the need for enhanced safety and efficiency. Early maritime navigation relied heavily on human skill and manual labor, while modern vessels integrate automated systems for engine control, navigation, and monitoring, reducing human error and operational costs. Your ability to understand this progression highlights the critical role automation now plays in optimizing maritime operations and crew workload.

Key Technologies in Shipboard Automation

Key technologies in shipboard automation include integrated bridge systems (IBS), dynamic positioning systems (DPS), and automated engine control systems (AECS), which enhance operational accuracy and safety. Advanced sensors, radar, and GPS provide real-time data for precise navigation and collision avoidance, reducing human error common in manual operations. Machine learning algorithms and predictive maintenance tools further optimize performance and minimize downtime on automated vessels.

Core Processes of Manual Ship Operation

Core processes of manual ship operation include navigation, engine room monitoring, cargo handling, and safety management performed by crew members relying on experience and real-time decision-making. Manual control requires continuous human intervention for steering, engine adjustments, and troubleshooting mechanical issues to ensure vessel stability and compliance with maritime regulations. These processes emphasize situational awareness, manual skill, and coordination among officers to maintain efficient and safe ship operations.

Efficiency and Productivity Comparison

Shipboard automation significantly enhances efficiency by enabling continuous monitoring and control of vessel systems, reducing human error and minimizing downtime. Manual operation, while offering flexibility and hands-on control, often results in slower response times and increased labor costs due to the need for constant crew intervention. Studies show automated systems improve overall productivity by optimizing fuel consumption, route management, and maintenance scheduling, leading to cost savings and higher operational throughput.

Safety and Risk Management Differences

Shipboard automation enhances safety by continuously monitoring systems and detecting anomalies faster than manual operation, reducing human error and response time during emergencies. Manual operation relies heavily on crew vigilance and experience, increasing the risk of oversight and delayed reactions to hazardous situations. Your ship's risk management becomes more proactive with automation, enabling predictive maintenance and real-time decision support to minimize accidents and operational downtime.

Impact on Crew Skills and Training Requirements

Shipboard automation significantly reduces the need for manual tasks, shifting crew skills from hands-on operations to system monitoring and technical troubleshooting. This transition demands specialized training in software, sensors, and automated control systems to ensure safe and efficient vessel management. Your crew must adapt by developing strong digital competencies alongside traditional maritime knowledge to maintain operational effectiveness.

Operational Costs and Economic Implications

Shipboard automation significantly reduces operational costs by minimizing crew requirements and enhancing fuel efficiency through precise navigation and engine control. Manual operation demands higher labor expenses and increases the risk of human error, which can lead to costly delays and maintenance issues. Investing in automation technology can improve your vessel's economic performance by lowering long-term expenses and optimizing resource utilization.

Environmental Impact: Automation vs Manual Control

Shipboard automation significantly reduces environmental impact by optimizing fuel consumption and minimizing emissions through precise engine and navigation control. Manual operation often leads to less efficient fuel use and higher greenhouse gas emissions due to human error and slower response times. Your vessel's environmental footprint can be minimized by adopting automated systems that ensure consistent compliance with ecological regulations and real-time monitoring of pollutant levels.

Future Trends in Maritime Operations

Shipboard automation is rapidly advancing with the integration of AI and IoT technologies, enabling predictive maintenance, real-time monitoring, and enhanced safety protocols. Manual operation remains crucial for emergency decision-making and complex navigational tasks where human judgment outperforms automated systems. Future trends emphasize hybrid models combining automated systems with skilled crew, optimizing efficiency while maintaining operational resilience in maritime environments.

Shipboard automation vs manual operation Infographic

libmatt.com

libmatt.com