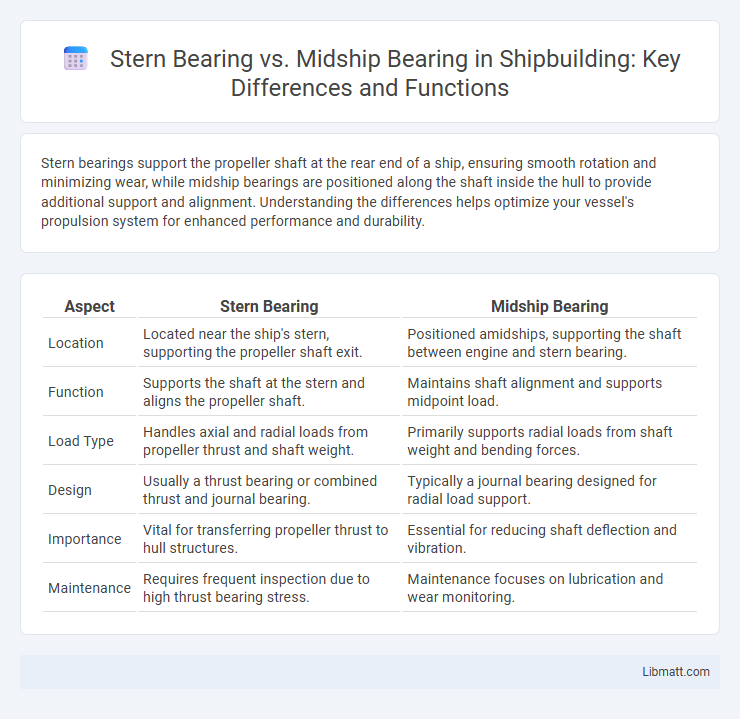

Stern bearings support the propeller shaft at the rear end of a ship, ensuring smooth rotation and minimizing wear, while midship bearings are positioned along the shaft inside the hull to provide additional support and alignment. Understanding the differences helps optimize your vessel's propulsion system for enhanced performance and durability.

Table of Comparison

| Aspect | Stern Bearing | Midship Bearing |

|---|---|---|

| Location | Located near the ship's stern, supporting the propeller shaft exit. | Positioned amidships, supporting the shaft between engine and stern bearing. |

| Function | Supports the shaft at the stern and aligns the propeller shaft. | Maintains shaft alignment and supports midpoint load. |

| Load Type | Handles axial and radial loads from propeller thrust and shaft weight. | Primarily supports radial loads from shaft weight and bending forces. |

| Design | Usually a thrust bearing or combined thrust and journal bearing. | Typically a journal bearing designed for radial load support. |

| Importance | Vital for transferring propeller thrust to hull structures. | Essential for reducing shaft deflection and vibration. |

| Maintenance | Requires frequent inspection due to high thrust bearing stress. | Maintenance focuses on lubrication and wear monitoring. |

Introduction to Stern Bearing and Midship Bearing

Stern bearings support the propeller shaft at the aft end of a vessel, ensuring smooth rotation and alignment between the propulsion machinery and the propeller. Midship bearings provide intermediate support along the propeller shaft, minimizing deflection and vibrations during operation. Understanding the distinct roles of stern and midship bearings helps maintain the efficiency and reliability of your ship's propulsion system.

Definition and Function of Stern Bearing

The stern bearing is a crucial component located at the aft end of a ship's propeller shaft, providing support and alignment to ensure smooth rotation and reduce friction. It primarily functions to bear the radial load of the propeller shaft and prevent excessive vibration, which enhances propulsion efficiency and protects the shaft from damage. You rely on the stern bearing to maintain the stability and operational integrity of the vessel's propulsion system, distinguishing it from the midship bearing that offers intermediate support along the shaft.

Definition and Function of Midship Bearing

Midship bearing is a crucial support component located near the center of a ship's propulsion shaft, designed to stabilize and align the shaft, reducing vibration and wear. Unlike the stern bearing, which supports the shaft at the propeller end, the midship bearing ensures smooth transmission of power from the engine to the propeller by maintaining shaft alignment amid hull movements. Your vessel's operational efficiency and longevity depend significantly on the proper functioning of the midship bearing.

Key Differences Between Stern Bearing and Midship Bearing

Stern bearing supports the propeller shaft at the aft end of the ship, primarily handling thrust and preventing axial movement, while midship bearing provides lateral support along the shaft, maintaining alignment and reducing vibration. Stern bearings are typically designed to withstand axial forces generated by the propeller, whereas midship bearings focus on radial loads and shaft stability during operation. Understanding these key differences ensures your vessel's propulsion system operates efficiently with reduced wear and improved performance.

Materials Used in Stern Bearings vs. Midship Bearings

Stern bearings commonly use materials such as babbitt, bronze, or composite polymers designed for high-load resistance and corrosion protection in harsh underwater environments. Midship bearings typically feature alloy bronzes or white metals, optimized for supporting intermediate shaft sections with moderate loads and good wear resistance. Your choice of material should consider operating conditions, load distribution, and maintenance requirements to ensure optimal bearing performance.

Installation Location and Arrangement

Stern bearings are installed at the aft end of a ship's hull, supporting the propeller shaft as it exits the vessel, typically housed within a stern tube assembly. Midship bearings are positioned along the ship's hull amidships, providing critical support to the propeller shaft between the engine and stern bearing, ensuring proper alignment and load distribution. The arrangement of stern bearings is designed to withstand external water pressure and prevent water ingress, while midship bearings focus on maintaining shaft alignment and reducing vibration throughout the shaft line.

Advantages and Disadvantages: Stern Bearing

Stern bearings offer enhanced stability and reduced friction by supporting the propeller shaft near the stern, resulting in smoother vessel operation and improved fuel efficiency. However, they may be more susceptible to damage from underwater obstacles and require more frequent maintenance compared to midship bearings. Your choice between stern and midship bearings should consider the trade-off between improved propulsion performance and potential vulnerability in stern bearing placement.

Advantages and Disadvantages: Midship Bearing

Midship bearings offer significant advantages in reducing shaft deflection and minimizing vibration, which enhances the overall longevity and performance of the propulsion system. However, they can complicate shaft alignment and increase maintenance requirements due to their location amidships, where access is more restricted compared to stern bearings. The midship bearing's ability to support longer shafts effectively comes at the cost of added structural complexity and potential challenges in routine inspections.

Maintenance and Lifespan Considerations

Stern bearings typically endure higher loads and exposure to seawater, necessitating more frequent maintenance and corrosion-resistant materials to extend their lifespan. Midship bearings experience distributed loads and are less prone to direct environmental stress, allowing for longer service intervals and reduced maintenance efforts. Selecting appropriate lubrication and regular inspection routines are crucial for optimizing the durability and performance of both stern and midship bearings.

Application and Selection Criteria for Marine Bearings

Stern bearings are primarily designed to support the propeller shaft in the aft section of a ship, accommodating axial and radial loads while ensuring smooth rotation under harsh marine conditions. Midship bearings are installed amidship to stabilize the shaft, reduce vibration, and maintain alignment, typically handling higher radial loads due to hull flexing during navigation. Selection criteria for marine bearings include load capacity, lubrication type (water-lubricated or oil-lubricated), material corrosion resistance, operating speed, maintenance accessibility, and compatibility with shaft alignment to optimize performance and longevity in marine environments.

Stern bearing vs midship bearing Infographic

libmatt.com

libmatt.com