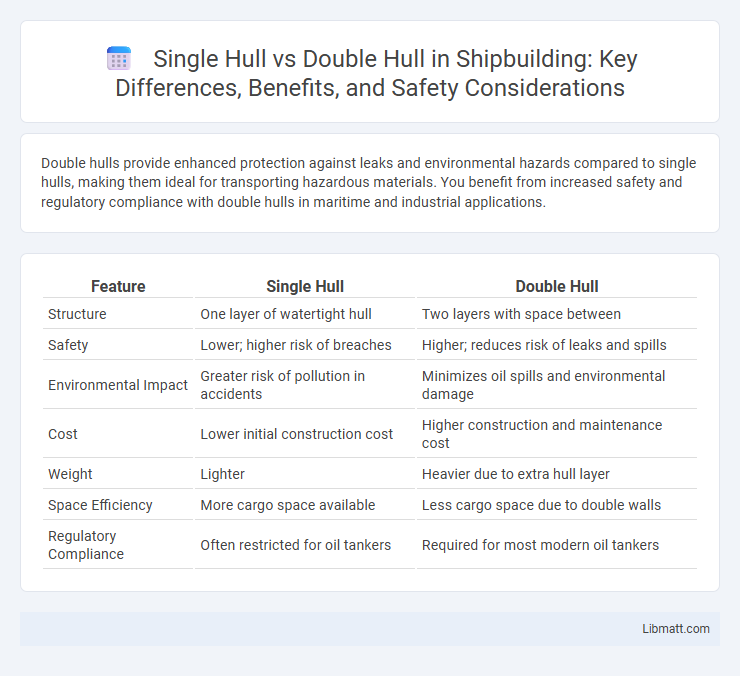

Double hulls provide enhanced protection against leaks and environmental hazards compared to single hulls, making them ideal for transporting hazardous materials. You benefit from increased safety and regulatory compliance with double hulls in maritime and industrial applications.

Table of Comparison

| Feature | Single Hull | Double Hull |

|---|---|---|

| Structure | One layer of watertight hull | Two layers with space between |

| Safety | Lower; higher risk of breaches | Higher; reduces risk of leaks and spills |

| Environmental Impact | Greater risk of pollution in accidents | Minimizes oil spills and environmental damage |

| Cost | Lower initial construction cost | Higher construction and maintenance cost |

| Weight | Lighter | Heavier due to extra hull layer |

| Space Efficiency | More cargo space available | Less cargo space due to double walls |

| Regulatory Compliance | Often restricted for oil tankers | Required for most modern oil tankers |

Introduction to Hull Designs

Single hull designs consist of one layer of watertight structure between the cargo and the sea, making them lighter but more vulnerable to breaches. Double hulls incorporate an additional outer layer separated by a space, enhancing protection against leaks and environmental damage in case of collisions or grounding. The choice between single and double hulls impacts vessel stability, maintenance costs, and compliance with international maritime safety regulations.

What Is a Single Hull?

A single hull is a ship design featuring only one layer of watertight material between the cargo and the water, making it more vulnerable to breaches and spills compared to double hull vessels. This design is commonly used in older tankers and cargo ships, where space efficiency and lower construction costs were prioritized over environmental safety. Understanding your vessel's hull type is crucial for assessing its risk profile and compliance with maritime regulations.

What Is a Double Hull?

A double hull features two layers of watertight hull surface with space between, providing enhanced protection against leaks or spills compared to a single hull, which only has one. This design significantly reduces the risk of environmental contamination in maritime accidents, especially for oil tankers and hazardous cargo vessels. Regulatory bodies like the International Maritime Organization (IMO) have mandated double hulls to improve tanker safety and prevent marine pollution.

Historical Evolution of Ship Hulls

The historical evolution of ship hulls reveals a transition from single hull designs to double hull constructions driven by safety and environmental concerns, especially after major oil spills in the late 20th century. Single hull vessels, predominant in the early maritime era, featured a single layer of plating, which made them more vulnerable to breaches and pollution risks. The adoption of double hulls in the 1990s, mandated by international regulations like MARPOL Annex I, introduced an additional protective layer between cargo and sea, significantly reducing the risk of oil discharge during collisions or groundings.

Structural Differences: Single vs Double Hull

Single hull vessels feature a single layer of watertight structure between the cargo and the sea, making them lighter but more vulnerable to breaches. Double hull ships incorporate two layers of hull plating with a void space between them, offering enhanced protection against leaks and collisions. Your choice between single hull and double hull impacts safety measures and environmental risk during maritime operations.

Safety and Environmental Considerations

Double hull designs provide enhanced safety by reducing the risk of oil spills in case of a hull breach, as the outer hull absorbs impact while the inner hull contains the cargo. Single hull vessels offer less protection, increasing the likelihood of environmental contamination during collisions or groundings. Your choice of hull type directly influences environmental risk management and compliance with international maritime safety regulations.

Cost and Maintenance Comparison

Single hull vessels generally have lower initial construction costs compared to double hull ships due to their simpler design and reduced material use. Maintenance expenses for single hulls tend to be higher over time because they offer less protection against corrosion and damage, leading to more frequent repairs. Choosing a double hull can optimize Your long-term investment by reducing maintenance frequency and increasing safety, despite the higher upfront cost.

Performance and Fuel Efficiency

Double hull vessels offer enhanced fuel efficiency by reducing hydrodynamic drag through improved stability and structural integrity, which can lead to lower overall fuel consumption compared to single hull ships. Single hull designs tend to be lighter, providing slightly better speed and maneuverability in calm waters but often sacrifice fuel efficiency due to increased resistance and less optimized weight distribution. Your choice between single hull and double hull impacts operational performance and fuel costs, with double hulls generally preferred for long-haul shipments prioritizing safety and efficiency.

Regulatory Requirements and Standards

Single hull vessels face stricter regulatory limitations under MARPOL Annex I due to higher environmental risks, leading to phase-outs in many jurisdictions. Double hull designs comply with International Maritime Organization (IMO) standards, offering enhanced oil spill protection and meeting regulations such as the Oil Pollution Act (OPA 90). Regulatory bodies globally mandate double hulls for new oil tankers to minimize marine pollution and improve vessel safety.

Choosing the Right Hull: Factors to Consider

Choosing the right hull, single or double, depends on factors like safety, environmental regulations, and operational costs. Double hulls offer enhanced protection against leaks and spills, making them ideal for transporting hazardous materials or navigating sensitive waters. You should evaluate vessel purpose, route, and compliance requirements to determine the most suitable hull design for your maritime operations.

Single hull vs double hull Infographic

libmatt.com

libmatt.com