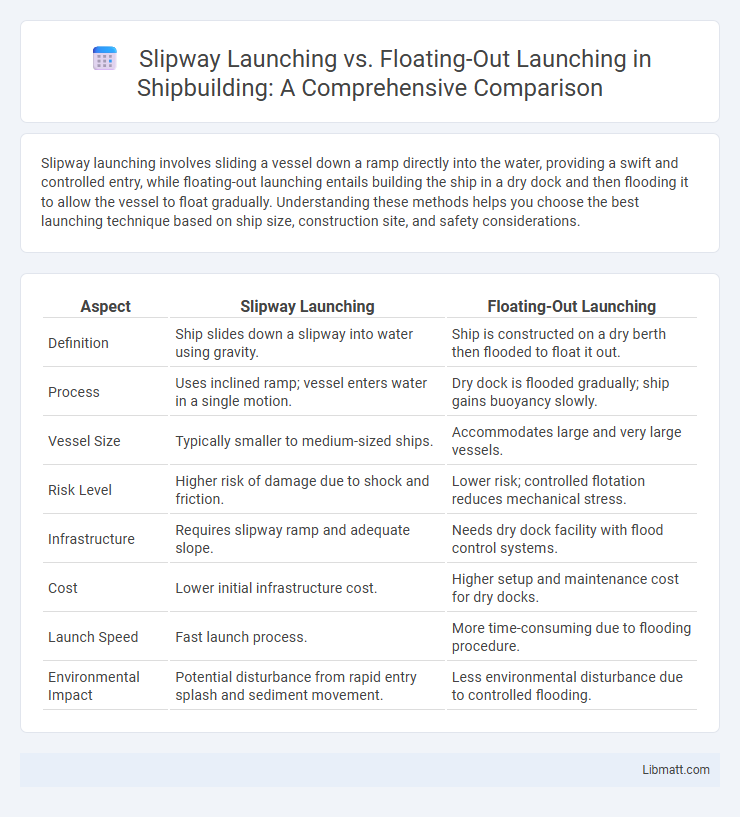

Slipway launching involves sliding a vessel down a ramp directly into the water, providing a swift and controlled entry, while floating-out launching entails building the ship in a dry dock and then flooding it to allow the vessel to float gradually. Understanding these methods helps you choose the best launching technique based on ship size, construction site, and safety considerations.

Table of Comparison

| Aspect | Slipway Launching | Floating-Out Launching |

|---|---|---|

| Definition | Ship slides down a slipway into water using gravity. | Ship is constructed on a dry berth then flooded to float it out. |

| Process | Uses inclined ramp; vessel enters water in a single motion. | Dry dock is flooded gradually; ship gains buoyancy slowly. |

| Vessel Size | Typically smaller to medium-sized ships. | Accommodates large and very large vessels. |

| Risk Level | Higher risk of damage due to shock and friction. | Lower risk; controlled flotation reduces mechanical stress. |

| Infrastructure | Requires slipway ramp and adequate slope. | Needs dry dock facility with flood control systems. |

| Cost | Lower initial infrastructure cost. | Higher setup and maintenance cost for dry docks. |

| Launch Speed | Fast launch process. | More time-consuming due to flooding procedure. |

| Environmental Impact | Potential disturbance from rapid entry splash and sediment movement. | Less environmental disturbance due to controlled flooding. |

Introduction to Ship Launching Methods

Slipway launching involves sliding the vessel down a ramp into the water, relying on gravity and controlled descent, which is ideal for smaller to medium-sized ships due to limited structural support. Floating-out launching consists of flooding a dry dock to allow the ship to buoyantly rise, accommodating larger, more complex vessels requiring precise positioning and minimal structural stress. Both methods are critical in shipbuilding, chosen based on vessel size, design, and engineering requirements.

Overview of Slipway Launching

Slipway launching involves moving a vessel down an inclined slipway directly into the water, using gravity to transition from land to sea. This method is efficient for small to medium-sized ships, enabling quick and controlled launches with minimal need for additional equipment. The slipway structure typically includes greased or roller-supported tracks to reduce friction and ensure smooth launching.

Overview of Floating-Out Launching

Floating-out launching involves moving the vessel from the construction site on a dry dock or building basin into water by flooding the dock. This method ensures gradual and controlled buoyancy, minimizing stress on the hull during transition. It is commonly used for large ships or when shipyards have limited shore space for slipway launching.

Historical Evolution of Launching Techniques

Slipway launching originates from ancient shipbuilding practices where vessels were constructed on inclined ramps and slid into the water, offering a straightforward method for early maritime civilizations. Floating-out launching emerged with the advancement of dry dock technology, allowing ships to be constructed afloat or in controlled environments before being gently floated out, greatly reducing structural stress during launch. Your choice between these methods can impact construction efficiency and vessel integrity, reflecting centuries of innovation in ship launch techniques.

Structural Requirements for Slipway Launching

Slipway launching demands robust structural support to withstand the vessel's weight as it slides directly into the water, requiring reinforced slipway surfaces and carefully designed cradle systems to distribute loads evenly. The slipway must have a precise slope angle and adequate strength in foundations and rails to prevent deformation under dynamic loads during launch. Your engineering team must ensure the slipway structure can endure repeated launches and environmental stresses for safety and operational efficiency.

Infrastructure Needed for Floating-Out Launching

Floating-out launching requires specialized infrastructure including a dry dock or a floating dock equipped with ballast systems to control vessel stability during launch. This method depends heavily on access to deep waterways and robust mooring facilities to safely maneuver the vessel after floating out. Your shipyard must have advanced pumping and dewatering systems to manage water levels and ensure a smooth transition from dry structure to floating vessel.

Safety Considerations in Both Methods

Slipway launching demands rigorous slope stability assessments and precise timing to prevent uncontrolled vessel descent, emphasizing controlled braking systems and effective water cushioning. Floating-out launching relies heavily on meticulous ballast management and robust mooring arrangements to ensure vessel stability and avoid impacts during transfer from dry dock to water. Both methods require comprehensive risk assessments and emergency response plans to mitigate hazards associated with vessel movement and environmental factors.

Cost Comparison: Slipway vs Floating-Out

Slipway launching typically incurs lower initial construction costs due to its simpler infrastructure requirements, whereas floating-out launching demands higher expenses for specialized dry docks and flotation facilities. Maintenance and operational costs for slipway launching remain moderate, but floating-out launching can increase costs owing to the complexity of managing water displacement and precise buoyancy control. Overall, slipway launching offers more cost-effective solutions for smaller vessels, while floating-out launching suits larger, heavier ships despite its higher investment.

Environmental Impact Assessment

Slipway launching typically involves a direct slide of vessels into the water, which can cause significant sediment disturbance and noise pollution affecting marine ecosystems. Floating-out launching allows ships to be constructed in a dry dock and gently floated, minimizing sediment disruption and reducing the release of pollutants into surrounding habitats. Environmental Impact Assessments for slipway launching must address shoreline erosion and habitat degradation more extensively compared to floating-out methods.

Choosing the Optimal Launching Method

Selecting the optimal launching method depends on factors like vessel size, site topography, and budget constraints. Slipway launching offers a cost-effective and straightforward approach suitable for smaller vessels and inclined shorelines, while floating-out launching is preferred for larger ships requiring stable, deepwater channels. Understanding these operational parameters ensures efficient deployment and minimizes damage risks during the critical launch phase.

Slipway launching vs floating-out launching Infographic

libmatt.com

libmatt.com