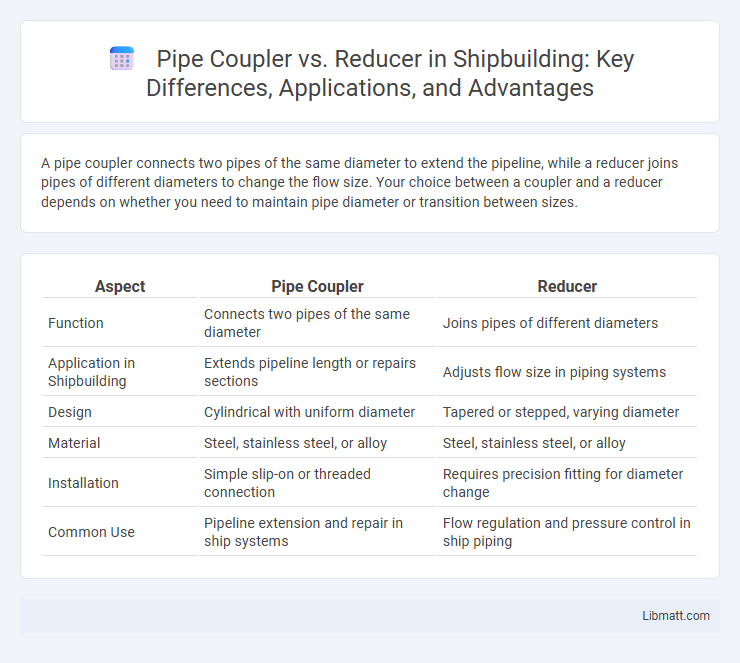

A pipe coupler connects two pipes of the same diameter to extend the pipeline, while a reducer joins pipes of different diameters to change the flow size. Your choice between a coupler and a reducer depends on whether you need to maintain pipe diameter or transition between sizes.

Table of Comparison

| Aspect | Pipe Coupler | Reducer |

|---|---|---|

| Function | Connects two pipes of the same diameter | Joins pipes of different diameters |

| Application in Shipbuilding | Extends pipeline length or repairs sections | Adjusts flow size in piping systems |

| Design | Cylindrical with uniform diameter | Tapered or stepped, varying diameter |

| Material | Steel, stainless steel, or alloy | Steel, stainless steel, or alloy |

| Installation | Simple slip-on or threaded connection | Requires precision fitting for diameter change |

| Common Use | Pipeline extension and repair in ship systems | Flow regulation and pressure control in ship piping |

Introduction to Pipe Coupler and Reducer

A pipe coupler is a fitting used to join two pipes of the same diameter, ensuring a secure and leak-proof connection in your plumbing or piping system. A reducer, on the other hand, connects pipes of different diameters, allowing for a smooth transition between varying sizes while maintaining flow efficiency. Choosing the right fitting depends on whether you need to connect pipes of equal or different dimensions to optimize your system's performance.

Definition and Function of Pipe Coupler

A pipe coupler is a fitting used to connect two pipes of the same diameter, enabling extension of pipeline length and flow continuity. It ensures a secure, leak-proof joint between identical pipes, maintaining consistent pressure and flow rates. Unlike reducers, which join pipes of different sizes to regulate fluid velocity, couplers prioritize uniform diameter connections for seamless pipe integration.

Definition and Function of Pipe Reducer

A pipe reducer is a fitting designed to connect two pipes of different diameters, enabling a smooth transition within piping systems. Unlike a coupler that joins pipes of the same size, the reducer adjusts flow rates and pressure by altering pipe diameter, ensuring system efficiency and preventing turbulence. Your choice between a reducer and coupler depends on whether you need to maintain or change pipe size in your installation.

Key Differences Between Coupler and Reducer

A pipe coupler connects two pipes of the same diameter to extend the pipeline, while a reducer joins pipes of different diameters, facilitating a smooth change in size. Couplers maintain uniform flow and pressure, whereas reducers adjust the flow characteristics by altering pipe size. Understanding these key differences ensures your piping system functions efficiently and meets design requirements.

Materials Used for Couplers and Reducers

Pipe couplers and reducers are typically made from durable materials such as stainless steel, carbon steel, PVC, and brass, ensuring compatibility with various piping systems and fluid types. Stainless steel and carbon steel provide high strength and corrosion resistance for industrial applications, while PVC and brass offer lightweight and cost-effective solutions for residential plumbing. Understanding these material options helps you select the right component for your specific pressure, temperature, and chemical resistance requirements.

Common Applications of Pipe Couplers

Pipe couplers are commonly used in plumbing and irrigation systems to join two pipes of the same diameter, ensuring a secure and leak-proof connection. They are essential in maintaining consistent pipe sizing in water supply lines, HVAC systems, and industrial piping networks. Couplers facilitate repairs and extensions by allowing easy replacement or addition of uniform-sized pipes without altering flow characteristics.

Common Applications of Pipe Reducers

Pipe reducers are commonly used in fluid handling systems to connect pipes of different diameters, optimizing flow dynamics in industries such as oil and gas, water treatment, and chemical processing. These fittings effectively manage pressure changes and reduce turbulence by smoothly transitioning pipe sizes, making them essential in pumping systems and pipelines. Unlike pipe couplers, which join pipes of the same diameter, reducers ensure efficient flow while preventing potential damage caused by abrupt size changes.

Installation Process: Coupler vs Reducer

The installation process of a pipe coupler involves aligning and joining two pipes of the same diameter, ensuring a secure and leak-proof connection with minimal effort. In contrast, a reducer requires fitting two pipes of different diameters, demanding precise measurement and careful adjustment to maintain proper flow dynamics and prevent pressure loss. Your choice between coupler and reducer impacts both installation time and system efficiency, depending on pipe size compatibility.

Advantages and Disadvantages of Each Fitting

Pipe couplers offer the advantage of connecting two pipes of the same diameter, ensuring a secure and leak-proof join with simple installation and cost-effectiveness. However, they cannot accommodate changes in pipe size, limiting their versatility in systems requiring diameter transitions. Reducers enable smooth changes between different pipe sizes, improving flow efficiency and reducing turbulence, but they tend to be more expensive and may require additional fittings to accommodate complex piping layouts.

Choosing the Right Fitting for Your Piping System

Selecting the right fitting for your piping system depends on the specific function you need: pipe couplers connect two pipes of the same diameter, ensuring a uniform flow and reliable joint, while reducers join pipes of different diameters, facilitating smooth transitions and preventing pressure loss. Understanding the diameter, material compatibility, and flow requirements of your pipes will guide you in choosing between a coupler and a reducer. Proper selection optimizes system performance, reduces maintenance issues, and extends the lifespan of your piping infrastructure.

Pipe coupler vs reducer Infographic

libmatt.com

libmatt.com