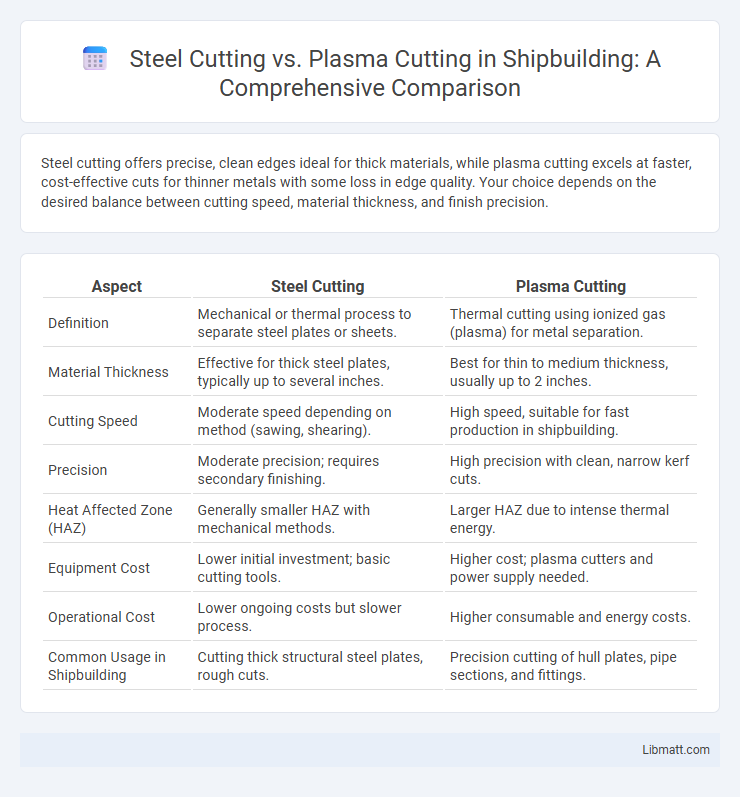

Steel cutting offers precise, clean edges ideal for thick materials, while plasma cutting excels at faster, cost-effective cuts for thinner metals with some loss in edge quality. Your choice depends on the desired balance between cutting speed, material thickness, and finish precision.

Table of Comparison

| Aspect | Steel Cutting | Plasma Cutting |

|---|---|---|

| Definition | Mechanical or thermal process to separate steel plates or sheets. | Thermal cutting using ionized gas (plasma) for metal separation. |

| Material Thickness | Effective for thick steel plates, typically up to several inches. | Best for thin to medium thickness, usually up to 2 inches. |

| Cutting Speed | Moderate speed depending on method (sawing, shearing). | High speed, suitable for fast production in shipbuilding. |

| Precision | Moderate precision; requires secondary finishing. | High precision with clean, narrow kerf cuts. |

| Heat Affected Zone (HAZ) | Generally smaller HAZ with mechanical methods. | Larger HAZ due to intense thermal energy. |

| Equipment Cost | Lower initial investment; basic cutting tools. | Higher cost; plasma cutters and power supply needed. |

| Operational Cost | Lower ongoing costs but slower process. | Higher consumable and energy costs. |

| Common Usage in Shipbuilding | Cutting thick structural steel plates, rough cuts. | Precision cutting of hull plates, pipe sections, and fittings. |

Introduction to Steel Cutting and Plasma Cutting

Steel cutting involves using mechanical tools like saws or laser cutters to precisely shape and size steel materials for various industrial applications. Plasma cutting utilizes a high-velocity jet of ionized gas to melt and blow away metal, offering faster and more versatile cutting for conductive metals such as steel and aluminum. Your choice between steel cutting and plasma cutting depends on factors like material thickness, precision requirements, and project speed.

Key Differences Between Steel Cutting and Plasma Cutting

Steel cutting typically involves methods such as laser, waterjet, or mechanical saws, offering high precision and smooth edges suitable for structural or artistic applications. Plasma cutting uses a high-velocity jet of ionized gas to melt and blow away metal, making it faster and more cost-effective for cutting thick steel plates but with a rougher finish. Key differences include plasma's ability to cut electrically conductive metals quickly and steel cutting's versatility across materials and finer tolerances.

Overview of Steel Cutting Techniques

Steel cutting techniques include plasma cutting and traditional methods such as oxy-fuel and laser cutting. Plasma cutting uses an ionized gas to cut through conductive metals quickly with high precision and minimal heat distortion. This method contrasts with oxy-fuel cutting, which relies on combustion and is generally slower and less precise but effective for thicker steel plates.

How Plasma Cutting Works

Plasma cutting works by generating an electrical arc through a high-velocity jet of ionized gas, or plasma, that melts and blows away metal from the cutting area. The plasma reaches temperatures of up to 30,000degF, enabling it to cut through thick and conductive metals with precision and speed. This method is effective for cutting steel, stainless steel, aluminum, and other conductive metals with minimal thermal distortion compared to traditional steel cutting techniques.

Material Suitability: Steel Cutting vs Plasma Cutting

Steel cutting methods like oxy-fuel cutting are highly suitable for thick carbon steel due to their precise control and deep penetration, while plasma cutting excels in cutting a variety of metals, including stainless steel, aluminum, and thin to medium-thickness steel with high speed and clean edges. Plasma cutting offers versatility across conductive metals by utilizing ionized gas to achieve fast, accurate cuts in thinner materials, whereas steel cutting techniques are preferred for heavy-duty applications requiring robust performance on thick steel plates. Selection depends on material type, thickness, and desired cut quality, with plasma cutting favored for diverse metals and steel cutting for heavy, thick steel components.

Precision and Edge Quality Comparison

Steel cutting with laser technology offers superior precision and edge quality compared to plasma cutting, delivering clean, smooth edges with minimal dross and heat-affected zones. Plasma cutting, while faster and cost-effective, typically produces rougher edges and wider kerf width, requiring additional finishing for applications demanding tight tolerances. The enhanced accuracy of laser steel cutting makes it ideal for intricate designs and high-precision manufacturing processes.

Speed and Efficiency Analysis

Plasma cutting offers significantly higher speed and efficiency compared to traditional steel cutting methods, especially on thicker materials up to 1 inch or more. Its ability to deliver precise, high-temperature ionized gas allows for rapid, clean cuts with minimal heat distortion, reducing post-cutting processing time. Your choice of cutting technique directly impacts production throughput and operational costs, with plasma cutting often preferred for industrial applications demanding fast, accurate steel fabrication.

Cost Factors and Budget Considerations

Steel cutting with oxy-fuel methods generally incurs lower initial equipment costs but higher ongoing fuel expenses, making it budget-friendly for thick steel projects with less frequent use. Plasma cutting requires a higher upfront investment in technology and consumables but offers faster cutting speeds and greater precision, reducing labor costs and material waste for intricate or high-volume jobs. Evaluating project scale, steel thickness, and required accuracy is crucial to balancing equipment costs against operational efficiency in steel versus plasma cutting decisions.

Safety and Environmental Impacts

Steel cutting with traditional methods often produces fewer fumes and poses less risk of thermal hazards compared to plasma cutting, which generates intense heat and can release harmful gases requiring proper ventilation. Plasma cutting involves bright arcs and molten metal splatter, necessitating protective gear to prevent burns and eye damage, while steel cutting methods like sawing reduce direct exposure to such hazards. Your choice impacts workplace safety and environmental emissions, with steel cutting generally offering a cleaner, lower-risk option if minimizing harmful environmental and safety effects is a priority.

Choosing the Right Cutting Method for Your Project

Steel cutting offers precise, smooth edges ideal for thick materials, while plasma cutting excels in speed and versatility for various metal types and thicknesses. Your project's requirements for accuracy, material thickness, and budget will determine the most effective cutting method. Assessing these factors ensures optimal results and cost-efficiency in metal fabrication.

Steel cutting vs plasma cutting Infographic

libmatt.com

libmatt.com