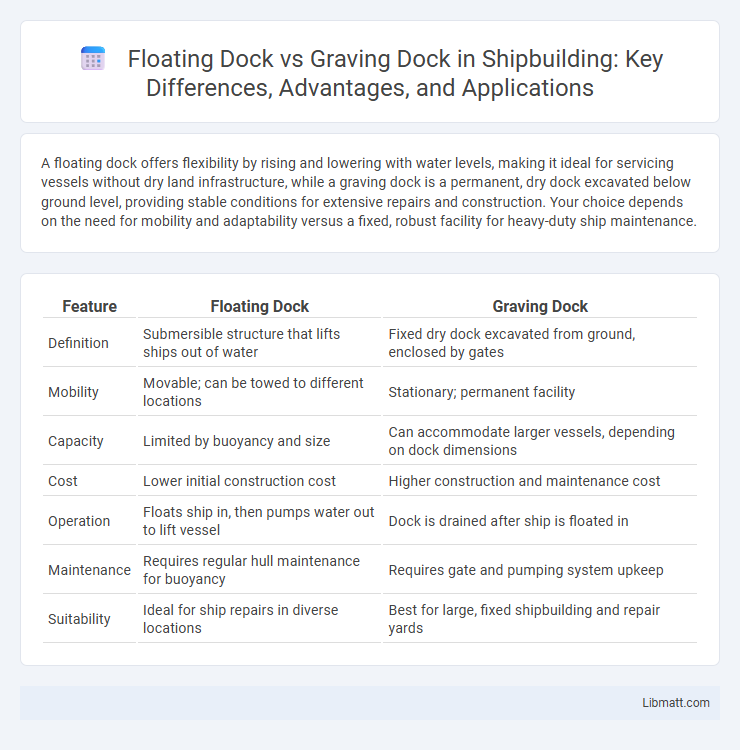

A floating dock offers flexibility by rising and lowering with water levels, making it ideal for servicing vessels without dry land infrastructure, while a graving dock is a permanent, dry dock excavated below ground level, providing stable conditions for extensive repairs and construction. Your choice depends on the need for mobility and adaptability versus a fixed, robust facility for heavy-duty ship maintenance.

Table of Comparison

| Feature | Floating Dock | Graving Dock |

|---|---|---|

| Definition | Submersible structure that lifts ships out of water | Fixed dry dock excavated from ground, enclosed by gates |

| Mobility | Movable; can be towed to different locations | Stationary; permanent facility |

| Capacity | Limited by buoyancy and size | Can accommodate larger vessels, depending on dock dimensions |

| Cost | Lower initial construction cost | Higher construction and maintenance cost |

| Operation | Floats ship in, then pumps water out to lift vessel | Dock is drained after ship is floated in |

| Maintenance | Requires regular hull maintenance for buoyancy | Requires gate and pumping system upkeep |

| Suitability | Ideal for ship repairs in diverse locations | Best for large, fixed shipbuilding and repair yards |

Introduction to Docking Systems

Floating docks and graving docks serve as essential maritime infrastructure for vessel maintenance and repairs. Floating docks are portable platforms that can be submerged to allow ships to float in and then raised to lift the vessel out of the water, making them ideal for flexibility and quick deployment in various locations. Graving docks, also known as dry docks, are permanent, excavated basins with gates that can be sealed and pumped dry, providing a stable and controlled environment for extensive shipbuilding and major repairs.

What is a Floating Dock?

A floating dock is a type of mobile platform designed to lift vessels out of the water for maintenance, repair, or storage by using buoyancy and mechanical lifting systems. Unlike a graving dock, which is a fixed, excavated basin, a floating dock can be relocated and adjusted to accommodate different ship sizes and water depths. This flexibility makes floating docks ideal for shipyards requiring versatile and efficient dry docking solutions.

What is a Graving Dock?

A graving dock is a fixed, narrow basin constructed from concrete or masonry, designed to be flooded and drained for the purpose of ship maintenance and repairs. It allows vessels to be floated in, sealed off from water, and drained so that the hull is exposed above the waterline for thorough inspection, cleaning, or construction. Unlike floating docks that rise and lower with water levels, graving docks provide a stable, dry environment critical for heavy-duty shipbuilding and repair work.

Construction and Design Differences

Floating docks consist of buoyant platforms supported by pontoons that can be submerged or raised to allow ship entry, offering flexibility and mobility with modular construction using steel or concrete. Graving docks are permanent, dry dock structures excavated into land and lined with reinforced concrete walls and a watertight gate, designed for heavy-duty ship repairs and maintenance with a focus on structural stability. The key design difference lies in floating docks' adaptability to water levels versus graving docks' fixed, land-based infrastructure requiring extensive civil engineering.

Installation and Setup Requirements

Floating docks require minimal site preparation and can be installed quickly by positioning the structure on the water with anchors or pilings, making them ideal for flexible locations. Graving docks demand extensive excavation, concrete construction, and heavy equipment, requiring substantial time and skilled labor for setup at a fixed site. Your choice depends on whether you need rapid deployment and mobility or a permanent, high-capacity docking facility.

Operational Flexibility and Mobility

Floating docks offer superior operational flexibility and mobility by allowing vessels to be lifted and moved to different locations with ease, making them ideal for temporary repairs or shipbuilding in various environments. Graving docks, being fixed structures built into the shoreline, provide limited mobility but excel in handling larger ships needing extensive repairs due to their stability and capacity. Your choice depends on whether you prioritize the ability to relocate the dock or require a robust, permanent facility for heavy-duty maintenance.

Cost Comparison: Floating Dock vs Graving Dock

Floating docks generally incur lower initial construction and maintenance costs compared to graving docks due to their modular design and reduced excavation requirements. Graving docks demand significant capital investment for excavation, waterproofing, and structural reinforcement, which can elevate both upfront and long-term expenses. Operational flexibility and site-specific factors also influence cost effectiveness, with floating docks offering advantages in mobility and adaptability over rigid graving dock structures.

Maintenance and Durability

Floating docks require regular inspections and maintenance of their pontoons and ballast systems to ensure buoyancy and stability, with corrosion protection being critical due to constant water exposure. Graving docks, constructed from reinforced concrete and steel, offer superior durability and reduced maintenance frequency but demand periodic cleaning and repairs to withstand structural stress and water ingress. Both dock types benefit from corrosion-resistant materials and protective coatings to prolong service life, but graving docks typically incur higher initial construction costs offset by their long-term resilience.

Environmental Impact and Sustainability

Floating docks minimize environmental disruption by avoiding extensive seabed excavation and reducing habitat destruction compared to graving docks. Graving docks often involve significant land reclamation and dredging, leading to sediment displacement and potential pollution risks. Your choice of a floating dock supports sustainability by promoting less invasive construction and preserving surrounding marine ecosystems.

Choosing the Right Dock: Key Considerations

Selecting between a floating dock and a graving dock depends on factors such as water depth, vessel size, and construction costs. Floating docks offer flexibility and are ideal for varied water conditions, while graving docks provide stability for heavy or large-scale repairs by being built on dry land. Evaluating maintenance requirements, environmental impact, and project budget is crucial for making an informed decision.

Floating dock vs graving dock Infographic

libmatt.com

libmatt.com