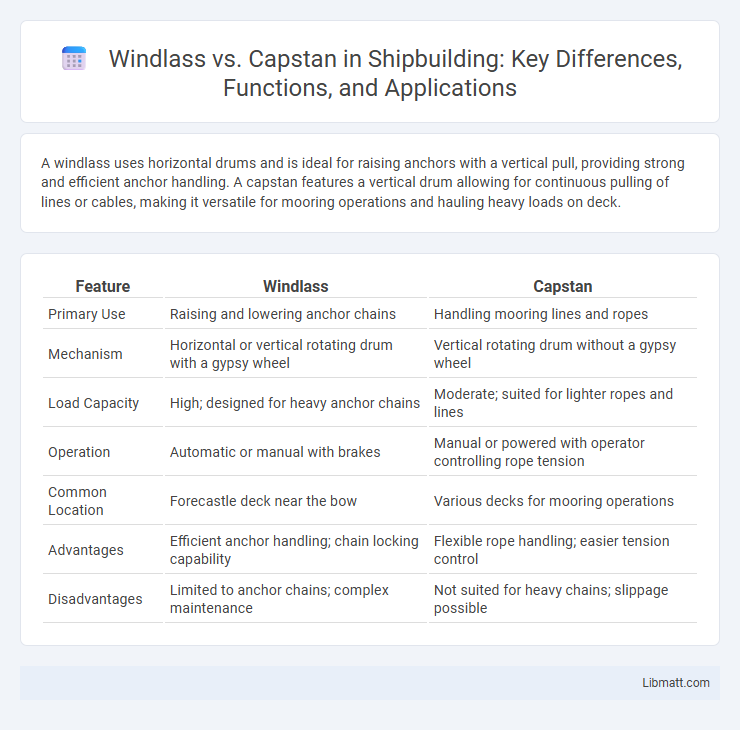

A windlass uses horizontal drums and is ideal for raising anchors with a vertical pull, providing strong and efficient anchor handling. A capstan features a vertical drum allowing for continuous pulling of lines or cables, making it versatile for mooring operations and hauling heavy loads on deck.

Table of Comparison

| Feature | Windlass | Capstan |

|---|---|---|

| Primary Use | Raising and lowering anchor chains | Handling mooring lines and ropes |

| Mechanism | Horizontal or vertical rotating drum with a gypsy wheel | Vertical rotating drum without a gypsy wheel |

| Load Capacity | High; designed for heavy anchor chains | Moderate; suited for lighter ropes and lines |

| Operation | Automatic or manual with brakes | Manual or powered with operator controlling rope tension |

| Common Location | Forecastle deck near the bow | Various decks for mooring operations |

| Advantages | Efficient anchor handling; chain locking capability | Flexible rope handling; easier tension control |

| Disadvantages | Limited to anchor chains; complex maintenance | Not suited for heavy chains; slippage possible |

Introduction to Windlass and Capstan

A windlass is a horizontal or vertical rotating drum used on ships to raise and lower anchors by winding a chain or rope, while a capstan is a vertical-axled rotating machine primarily used for handling mooring lines and cables. Windlasses provide mechanical advantage through gear trains, facilitating heavy lifting tasks efficiently, whereas capstans emphasize rotational motion for controlled tensioning and pulling of lines. Both are essential shipboard equipment designed to manage heavy loads, but their structural design and operational focus differ markedly.

Key Differences Between Windlass and Capstan

Windlass and capstan are both mechanical devices used on ships for handling anchor chains and ropes, but they differ in design and function. A windlass features a horizontal drum around which the anchor chain is wound, providing controlled lifting and lowering of the anchor, while a capstan consists of a vertical drum primarily used for hauling ropes or cables by wrapping them around the drum. Understanding these key differences helps you select the right equipment for specific maritime anchoring and mooring operations.

How a Windlass Works

A windlass operates by using a horizontal or vertical drum powered by an electric, hydraulic, or manual system to haul and control anchor chains or ropes efficiently. This mechanism provides the mechanical advantage needed to lift heavy anchors and secure the vessel with minimal effort. Your boat's windlass ensures smooth anchoring operations by maintaining consistent tension and preventing slack in the anchor rode.

How a Capstan Functions

A capstan functions by using a vertical rotating drum powered either manually or by an electric motor to pull in heavy loads, such as ship anchors or mooring lines. The rope or cable is wrapped around the drum, and the friction generated by the tension allows controlled movement without slipping. Unlike a windlass, which typically uses a horizontal axle with a gypsy wheel for anchor chains, a capstan excels in continuous pulling tasks with smooth, steady torque.

Applications of Windlass in Maritime Operations

Windlasses are essential in maritime operations for anchor handling, enabling ships to raise and lower anchors efficiently and safely. They provide mechanical advantage through a horizontal drum design, allowing precise control over heavy anchor chains in harbors and offshore environments. Commonly used on cargo ships, naval vessels, and offshore platforms, windlasses ensure stable anchoring critical for vessel positioning and operational safety.

Common Uses of Capstan in Shipping

Capstans in shipping are primarily used for handling heavy mooring lines and anchor chains on vessels, providing controlled and continuous pulling power. They are often employed in docking procedures to secure ships safely to piers and wharves, ensuring stability during loading and unloading. Unlike windlasses, capstans excel in vertical line hauling where space constraints or specific operation demands require efficient vertical torque application.

Advantages of Using a Windlass

Using a windlass provides efficient anchoring by automating the raising and lowering of the anchor, significantly reducing manual labor and time. The mechanical advantage of a windlass allows it to handle heavier anchors and longer chains, enhancing safety and control during anchoring operations. Its compact design integrates seamlessly into the deck, optimizing space while delivering reliable performance in various marine conditions.

Benefits of Choosing a Capstan

Choosing a capstan offers superior control and continuous pulling power, making it ideal for heavy-duty marine and industrial applications. The capstan's design allows for smooth handling of ropes or cables, minimizing wear and enhancing safety in your operations. Its versatility and efficiency provide a reliable solution for managing large loads compared to a traditional windlass.

Factors to Consider: Windlass vs Capstan

Choosing between a windlass and a capstan depends on factors such as the size and type of your vessel, the weight of the anchor, and the frequency of use. Windlasses provide automated anchor handling and are ideal for heavy anchors and larger boats, while capstans offer manual or electric operation suited for lighter anchors and smaller vessels. Your decision should also consider power source availability, installation space, and maintenance requirements to ensure optimal performance and reliability.

Which is Better: Windlass or Capstan?

Choosing between a windlass and a capstan depends on your specific anchoring needs and vessel size; a windlass offers powerful, automated anchor handling ideal for larger boats, while a capstan provides versatile, manual rope management suited for smaller vessels. Windlasses excel in efficiency and ease of use during anchor retrieval, reducing manual labor and enhancing safety. Your decision should consider factors like anchor weight, boat size, and typical anchoring conditions to determine which system offers the best performance and convenience.

Windlass vs capstan Infographic

libmatt.com

libmatt.com