Marine growth prevention systems use ultrasonic or electromagnetic technology to inhibit biofouling without chemicals, offering an eco-friendly and low-maintenance alternative to traditional antifouling paint. Your choice depends on vessel type, environmental regulations, and maintenance preferences, with prevention systems reducing the need for frequent repainting and minimizing hazardous chemical exposure.

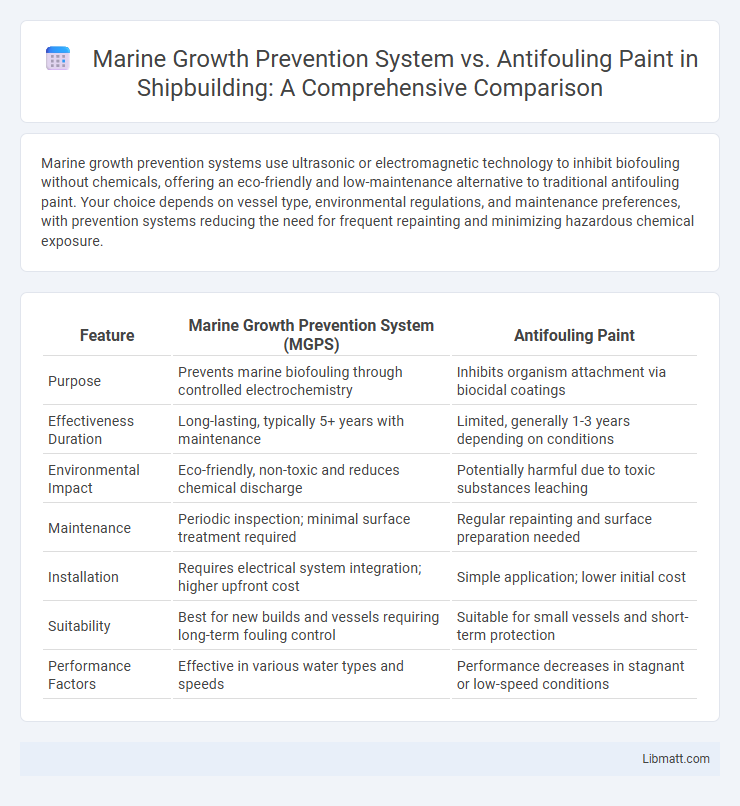

Table of Comparison

| Feature | Marine Growth Prevention System (MGPS) | Antifouling Paint |

|---|---|---|

| Purpose | Prevents marine biofouling through controlled electrochemistry | Inhibits organism attachment via biocidal coatings |

| Effectiveness Duration | Long-lasting, typically 5+ years with maintenance | Limited, generally 1-3 years depending on conditions |

| Environmental Impact | Eco-friendly, non-toxic and reduces chemical discharge | Potentially harmful due to toxic substances leaching |

| Maintenance | Periodic inspection; minimal surface treatment required | Regular repainting and surface preparation needed |

| Installation | Requires electrical system integration; higher upfront cost | Simple application; lower initial cost |

| Suitability | Best for new builds and vessels requiring long-term fouling control | Suitable for small vessels and short-term protection |

| Performance Factors | Effective in various water types and speeds | Performance decreases in stagnant or low-speed conditions |

Understanding Marine Growth and Its Impact

Marine growth, including barnacles, algae, and mussels, severely affects the efficiency and durability of submerged surfaces by increasing drag, fuel consumption, and maintenance costs. Marine growth prevention systems use physical or ultrasonic technologies to inhibit organism attachment, providing an environmentally friendly alternative to traditional antifouling paints, which release biocides to deter fouling but can harm marine ecosystems. Understanding your choice between these methods is crucial for balancing operational efficiency and ecological responsibility in managing biofouling on vessels and structures.

Overview of Marine Growth Prevention Systems

Marine Growth Prevention Systems (MGPS) use non-toxic methods like low-voltage electric currents to inhibit the accumulation of marine organisms on submerged structures, offering an environmentally friendly alternative to traditional antifouling paint. Unlike antifouling paint, which relies on biocides to prevent fouling but requires periodic reapplication and can harm marine life, MGPS provide continuous protection with minimal maintenance. Your choice of MGPS can enhance the longevity and efficiency of vessels and offshore installations while reducing ecological impact.

What is Antifouling Paint?

Antifouling paint is a specialized coating applied to ship hulls and underwater structures to prevent marine organism attachment and growth, which can reduce vessel efficiency and increase fuel consumption. The paint typically contains biocides, such as copper compounds, that deter barnacles, algae, and other biofouling species by releasing toxic substances in controlled amounts. Compared to marine growth prevention systems that use physical or chemical methods like ultrasonic waves or chlorination, antifouling paint provides a passive, long-term barrier against marine fouling.

Key Differences: Prevention Systems vs Antifouling Paint

Marine growth prevention systems use physical or chemical methods such as ultrasonic waves or electrochlorination to inhibit biofouling actively, while antifouling paint relies on biocides released gradually to prevent organism attachment. Prevention systems offer continuous protection with lower maintenance and environmental impact compared to antifouling paints, which require periodic reapplication and may contribute to marine pollution. Key differences include the mechanism of action, longevity, environmental safety, and maintenance frequency, making prevention systems a more sustainable option for long-term vessel hull protection.

Effectiveness in Marine Growth Control

Marine growth prevention systems use physical or chemical technologies such as ultrasonic waves or electrolysis to inhibit biofouling more consistently and with less environmental impact than traditional antifouling paint. Antifouling paint relies on biocides that wear off over time, reducing effectiveness and requiring frequent reapplication, while marine growth prevention systems maintain continuous protection. Your vessel benefits from improved hull performance and reduced maintenance costs when using advanced prevention systems over traditional antifouling coatings.

Environmental Impact and Regulations

Marine growth prevention systems (MGPS) offer an environmentally friendly alternative to traditional antifouling paints by minimizing the release of toxic biocides into marine ecosystems. Unlike antifouling paints, which often contain copper and other harmful substances regulated under international conventions such as the IMO's Biofouling Guidelines, MGPS rely on physical or non-toxic methods that comply more readily with stringent environmental regulations. Increased regulatory scrutiny on biocidal antifouling coatings drives the adoption of MGPS for sustainable marine vessel maintenance and reduced ecological harm.

Installation and Maintenance Requirements

Marine growth prevention systems require professional installation with electrical or ultrasonic components, demanding careful integration into your vessel's existing infrastructure. Maintenance involves periodic inspections and monitoring to ensure system efficacy, often resulting in lower ongoing upkeep compared to traditional methods. In contrast, antifouling paint needs surface preparation and regular recoating every 1-3 years, making its maintenance more labor-intensive and time-consuming.

Cost Analysis and Long-Term Value

Marine growth prevention systems typically involve higher upfront installation costs but offer lower maintenance expenses and longer service life compared to antifouling paint, which requires frequent reapplication and labor costs. Antifouling paint is more affordable initially but demands consistent renewal every 1 to 3 years to maintain efficacy against biofouling, increasing cumulative expenses over time. Evaluating total cost of ownership highlights that marine growth prevention systems provide superior long-term value through reduced downtime, improved fuel efficiency, and minimized environmental impact.

Suitability for Different Marine Vessels

Marine growth prevention systems are ideal for commercial vessels, offshore platforms, and large ships due to their long-term effectiveness and low maintenance requirements in harsh marine environments. Antifouling paint suits recreational boats and smaller vessels, offering a cost-effective and easy-to-apply solution with periodic reapplication needed to prevent biofouling. Choosing between these options depends on vessel size, operational duration, and maintenance capabilities, ensuring optimal protection against marine fouling.

Making the Right Choice for Your Vessel

Selecting between a marine growth prevention system (MGPS) and antifouling paint hinges on vessel type, operational area, and maintenance schedule. MGPS uses electrochlorination to create a protective ion barrier that prevents biofouling, offering longer-term vessel efficiency and reduced cleaning costs. Antifouling paint relies on biocides to deter organisms but requires frequent reapplication and can be less environmentally friendly, making MGPS a preferable choice for operators prioritizing sustainability and minimal downtime.

Marine growth prevention system vs antifouling paint Infographic

libmatt.com

libmatt.com