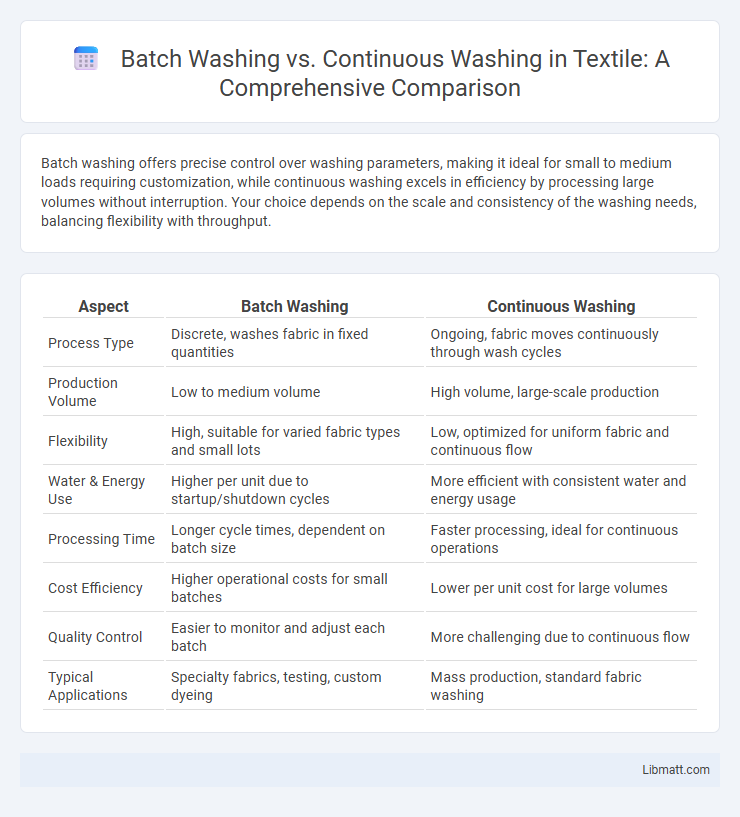

Batch washing offers precise control over washing parameters, making it ideal for small to medium loads requiring customization, while continuous washing excels in efficiency by processing large volumes without interruption. Your choice depends on the scale and consistency of the washing needs, balancing flexibility with throughput.

Table of Comparison

| Aspect | Batch Washing | Continuous Washing |

|---|---|---|

| Process Type | Discrete, washes fabric in fixed quantities | Ongoing, fabric moves continuously through wash cycles |

| Production Volume | Low to medium volume | High volume, large-scale production |

| Flexibility | High, suitable for varied fabric types and small lots | Low, optimized for uniform fabric and continuous flow |

| Water & Energy Use | Higher per unit due to startup/shutdown cycles | More efficient with consistent water and energy usage |

| Processing Time | Longer cycle times, dependent on batch size | Faster processing, ideal for continuous operations |

| Cost Efficiency | Higher operational costs for small batches | Lower per unit cost for large volumes |

| Quality Control | Easier to monitor and adjust each batch | More challenging due to continuous flow |

| Typical Applications | Specialty fabrics, testing, custom dyeing | Mass production, standard fabric washing |

Introduction to Batch and Continuous Washing

Batch washing processes involve treating a fixed quantity of material in separate, discrete cycles, allowing precise control over washing parameters for each load. Continuous washing systems operate by maintaining a steady flow of material through the washing unit, optimizing efficiency and throughput for large-scale industrial applications. Industrial sectors such as food processing, chemical manufacturing, and water treatment utilize both methods according to production volume and operational requirements.

Key Differences Between Batch and Continuous Washing

Batch washing processes materials in discrete, separate lots, allowing precise control over washing time and conditions for each batch. Continuous washing operates non-stop, continuously introducing and removing materials, ensuring consistent throughput and efficiency for large-scale production. Key differences include production scale, process control, and operational complexity, with batch washing suited for small, varied loads and continuous washing ideal for high-volume, uniform processing.

Process Overview: Batch Washing Systems

Batch washing systems involve processing materials in discrete, separate quantities, where each batch undergoes washing and rinsing steps in a controlled sequence. These systems offer precise control over washing parameters like temperature, detergent concentration, and cycle time for each batch, optimizing cleaning effectiveness. Commonly used in industries with varied product types or contamination levels, batch washing ensures thorough cleaning with flexibility for different specifications.

Process Overview: Continuous Washing Systems

Continuous washing systems provide an efficient and automated approach to cleaning materials by allowing a constant flow through washing stages without interruption. These systems maintain steady-state operation, ensuring consistent quality, minimizing downtime, and optimizing resource use compared to batch processes. Your facility can benefit from increased throughput and reduced labor costs by implementing continuous washing technology.

Efficiency Comparison: Batch vs Continuous Washing

Continuous washing systems offer higher efficiency by enabling uninterrupted processing, reducing downtime, and optimizing water and chemical usage compared to batch washing. Batch washing methods typically involve breaks between cycles, leading to longer total washing times and increased energy consumption per unit processed. Industrial settings favor continuous washing for scalability, consistent quality, and improved throughput in comparison to batch operations.

Energy and Water Consumption Analysis

Batch washing typically consumes more water and energy per cycle due to frequent machine startups and shutdowns, leading to inefficiencies in resource use. Continuous washing systems optimize energy and water consumption by maintaining steady operation, reducing thermal losses and minimizing water usage through recycling processes. Your choice between batch and continuous washing should consider these differences to maximize sustainability and cost savings in industrial cleaning applications.

Impact on Fabric Quality and Consistency

Batch washing offers precise control over washing parameters, resulting in consistent fabric quality for small production runs but can suffer from variability between batches. Continuous washing provides uniform treatment by maintaining constant processing conditions, enhancing fabric consistency and reducing quality fluctuations in high-volume manufacturing. The choice between methods depends on balancing production scale with desired fabric quality and consistency requirements.

Suitability for Various Industrial Applications

Batch washing suits industries requiring high flexibility and customization, such as pharmaceuticals and specialty chemicals, where precise control over washing cycles is essential. Continuous washing excels in large-scale, high-volume operations like food processing and textiles, offering consistent throughput and efficiency. Industrial sectors prioritize batch processes for complex, varied products and continuous systems for uniform, rapid production needs.

Cost Implications and ROI

Batch washing incurs higher labor and downtime costs due to intermittent operation, resulting in lower throughput and slower ROI. Continuous washing systems benefit from automation and steady processing, reducing operational expenses and accelerating return on investment through higher efficiency. The initial capital expenditure for continuous systems is greater, but long-term savings in energy and labor typically lead to superior cost-effectiveness.

Choosing the Right Washing System for Your Needs

Batch washing offers precise control over individual loads, making it ideal for smaller quantities or specialized cleaning requirements, while continuous washing excels in high-volume operations with consistent, uninterrupted processing. Your choice depends on factors like detergent efficiency, water usage, and production speed, where batch systems provide flexibility and continuous systems deliver scalability. Considering your operational scale and cleaning standards ensures you select a washing system that optimizes performance and cost-effectiveness.

Batch washing vs Continuous washing Infographic

libmatt.com

libmatt.com