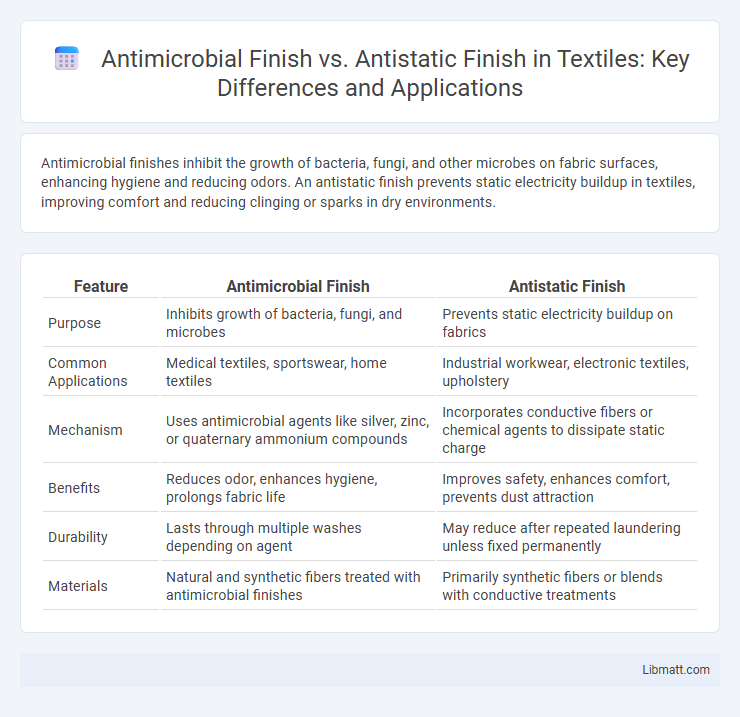

Antimicrobial finishes inhibit the growth of bacteria, fungi, and other microbes on fabric surfaces, enhancing hygiene and reducing odors. An antistatic finish prevents static electricity buildup in textiles, improving comfort and reducing clinging or sparks in dry environments.

Table of Comparison

| Feature | Antimicrobial Finish | Antistatic Finish |

|---|---|---|

| Purpose | Inhibits growth of bacteria, fungi, and microbes | Prevents static electricity buildup on fabrics |

| Common Applications | Medical textiles, sportswear, home textiles | Industrial workwear, electronic textiles, upholstery |

| Mechanism | Uses antimicrobial agents like silver, zinc, or quaternary ammonium compounds | Incorporates conductive fibers or chemical agents to dissipate static charge |

| Benefits | Reduces odor, enhances hygiene, prolongs fabric life | Improves safety, enhances comfort, prevents dust attraction |

| Durability | Lasts through multiple washes depending on agent | May reduce after repeated laundering unless fixed permanently |

| Materials | Natural and synthetic fibers treated with antimicrobial finishes | Primarily synthetic fibers or blends with conductive treatments |

Introduction to Textile Finishes

Antimicrobial finishes in textiles inhibit the growth of bacteria, fungi, and other microbes, enhancing fabric hygiene and durability. Antistatic finishes reduce static electricity buildup by improving the fabric's conductivity, preventing dust attraction and improving wearer comfort. These textile finishes are essential in specialized applications such as medical textiles, sportswear, and industrial fabrics to enhance functionality and user experience.

What is Antimicrobial Finish?

Antimicrobial finish refers to a treatment applied to textiles or surfaces that inhibits the growth of bacteria, fungi, and other microorganisms, enhancing hygiene and odor control. This finish uses agents such as silver ions or triclosan that disrupt microbial cell function, making it ideal for healthcare, sportswear, and home textiles. Your fabrics benefit from extended freshness and reduced risk of contamination when treated with antimicrobial finishes.

Mechanisms of Antimicrobial Action

Antimicrobial finishes inhibit the growth of bacteria, fungi, and other microorganisms through mechanisms such as disrupting cell membranes, interfering with microbial metabolism, or releasing antimicrobial agents like silver ions. Antistatic finishes, in contrast, work by dissipating static electricity on fabric surfaces using conductive compounds or by increasing surface conductivity, without targeting microbial activity. Your choice between these finishes depends on whether you need protection against microbes or control of static charge in textiles.

Key Applications of Antimicrobial Finishes

Antimicrobial finishes are primarily applied in healthcare textiles, sportswear, and home furnishings to inhibit microbial growth and reduce odors. These finishes enhance hygiene in hospital environments by preventing bacteria and fungi proliferation on patient gowns, bedding, and curtains. Their application in activewear and upholstery also extends fabric longevity and improves user comfort by maintaining cleanliness and freshness.

What is Antistatic Finish?

Antistatic finish is a textile treatment designed to reduce or eliminate static electricity buildup on fabric surfaces by increasing conductivity. This finish prevents static cling and sparks, enhancing comfort and safety in environments sensitive to static discharge, such as electronics manufacturing. Unlike antimicrobial finishes that inhibit microbial growth, antistatic finishes specifically target electrical charge control to improve fabric performance.

How Antistatic Finishes Work

Antistatic finishes work by incorporating conductive agents such as carbon fibers, metal salts, or conductive polymers into the fabric to dissipate static electricity, preventing the buildup of static charges on the surface. These finishes create a path for electrical charges to flow harmlessly to the ground, reducing static cling, sparks, and potential damage to sensitive electronic components. Unlike antimicrobial finishes that inhibit microbial growth, antistatic treatments specifically target the control of electrical charges in textile materials.

Key Uses of Antistatic Finishes

Antistatic finishes are primarily used in electronic manufacturing, cleanroom apparel, and industrial environments to prevent static electricity buildup that can damage sensitive components or attract dust and contaminants. These finishes improve product safety and performance by dissipating static charges on fabrics and surfaces. Your choice of antistatic finish enhances the durability and functionality of textiles used in environments where static control is critical.

Antimicrobial vs Antistatic: Main Differences

Antimicrobial finishes inhibit the growth of bacteria, fungi, and other microorganisms on surfaces, enhancing hygiene and reducing odors, whereas antistatic finishes prevent the buildup of static electricity by dissipating electrical charges to protect sensitive electronics and improve comfort. Antimicrobial treatments typically use agents like silver ions or triclosan, while antistatic coatings often involve conductive polymers or carbon-based materials. The primary difference lies in their functionality: antimicrobial is focused on microbiological protection, while antistatic is aimed at electrical charge control.

Selecting the Right Finish: Factors to Consider

Selecting the right finish for your fabric requires understanding the primary function of antimicrobial versus antistatic finishes--antimicrobial finishes inhibit the growth of bacteria and fungi, enhancing hygiene and fabric durability, while antistatic finishes reduce static electricity, improving comfort and safety in sensitive environments. Consider factors such as the intended use of the textile, exposure to moisture or contaminants, and the need for static control in the specific application. Your decision should align with the performance requirements and environmental conditions to ensure optimal fabric functionality and longevity.

Future Trends in Functional Textile Finishes

Antimicrobial finishes are evolving with nanotechnology and sustainable biocides to enhance fabric protection against bacteria and viruses, while antistatic finishes increasingly incorporate durable, eco-friendly agents that reduce static electricity without compromising comfort. You can expect future functional textile finishes to integrate smart, multifunctional properties combining antimicrobial, antistatic, and other performance benefits, driven by growing demand for hygiene, safety, and sustainability. Innovations in coating techniques and bio-based chemicals will define the next generation of high-performance, environmentally conscious textile treatments.

Antimicrobial finish vs Antistatic finish Infographic

libmatt.com

libmatt.com