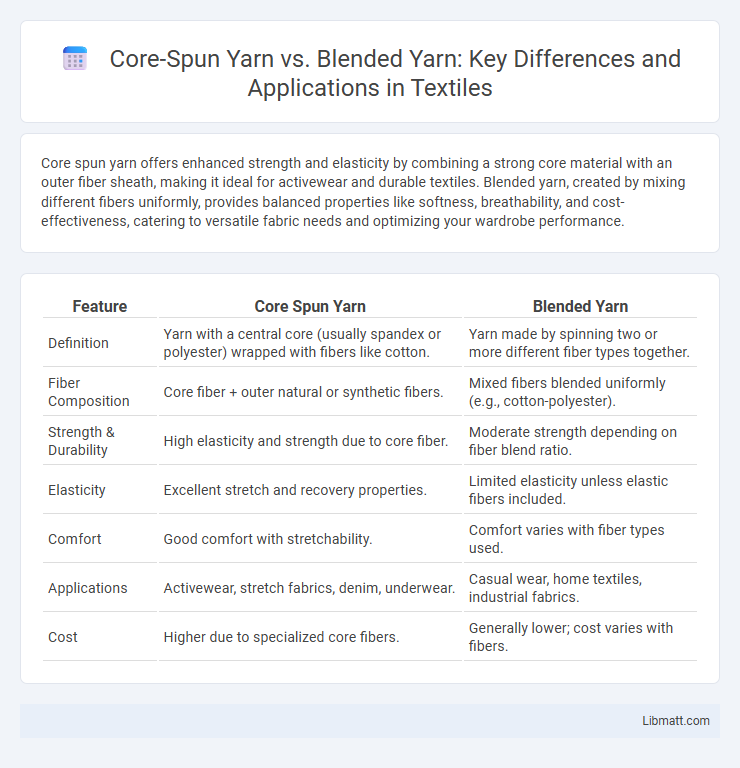

Core spun yarn offers enhanced strength and elasticity by combining a strong core material with an outer fiber sheath, making it ideal for activewear and durable textiles. Blended yarn, created by mixing different fibers uniformly, provides balanced properties like softness, breathability, and cost-effectiveness, catering to versatile fabric needs and optimizing your wardrobe performance.

Table of Comparison

| Feature | Core Spun Yarn | Blended Yarn |

|---|---|---|

| Definition | Yarn with a central core (usually spandex or polyester) wrapped with fibers like cotton. | Yarn made by spinning two or more different fiber types together. |

| Fiber Composition | Core fiber + outer natural or synthetic fibers. | Mixed fibers blended uniformly (e.g., cotton-polyester). |

| Strength & Durability | High elasticity and strength due to core fiber. | Moderate strength depending on fiber blend ratio. |

| Elasticity | Excellent stretch and recovery properties. | Limited elasticity unless elastic fibers included. |

| Comfort | Good comfort with stretchability. | Comfort varies with fiber types used. |

| Applications | Activewear, stretch fabrics, denim, underwear. | Casual wear, home textiles, industrial fabrics. |

| Cost | Higher due to specialized core fibers. | Generally lower; cost varies with fibers. |

Introduction to Core Spun Yarn and Blended Yarn

Core spun yarn consists of a central filament, usually made of synthetic fibers like polyester or nylon, wrapped with natural or synthetic fibers to combine strength and comfort. Blended yarn is created by mixing two or more different fiber types, such as cotton and polyester, at the fiber stage to produce yarns with balanced properties like durability, texture, and cost-effectiveness. Both yarn types are widely used in textiles for diverse applications, offering a mix of performance and aesthetic benefits tailored to specific end-uses.

Definition and Structure of Core Spun Yarn

Core spun yarn consists of a central filament, usually made of synthetic fibers like polyester or nylon, wrapped with staple fibers such as cotton or wool to combine strength and comfort. Its unique structure provides enhanced durability, stretch, and softness, differentiating it from traditional blended yarns, which mix different fibers uniformly throughout the strand. Understanding the definition and structure of core spun yarn helps you select the appropriate yarn type for applications requiring both performance and aesthetic qualities.

What is Blended Yarn?

Blended yarn is a textile yarn composed of two or more different types of fibers spun together to combine the best properties of each fiber. Common blends include cotton-polyester, wool-nylon, and acrylic-wool, offering enhanced durability, elasticity, and comfort compared to single-fiber yarns. This type of yarn is widely used in apparel and home textiles to optimize fabric performance and appearance.

Manufacturing Processes: Core Spun vs. Blended Yarn

Core spun yarn manufacturing involves wrapping staple fibers around a continuous filament core, typically made of synthetic fiber, to provide strength and elasticity, enhancing durability and performance. In contrast, blended yarn is created by mechanically mixing different types of fibers--such as cotton and polyester--before spinning them together into a single yarn, combining the properties of each fiber source uniformly. Understanding these manufacturing differences helps you select the appropriate yarn type for specific textile applications, ensuring optimal fabric characteristics.

Key Differences Between Core Spun and Blended Yarns

Core spun yarn consists of a central core fiber, often elastane or polyester, wrapped with another fiber, providing strength and stretch, while blended yarn is a homogeneous mixture of two or more fibers spun together for combined properties. Core spun yarn offers superior elasticity and durability, ideal for activewear, whereas blended yarn balances characteristics like softness, moisture-wicking, and cost-effectiveness across various textiles. Understanding these key differences helps you select the right yarn for your fabric's performance and end-use requirements.

Advantages of Core Spun Yarn

Core spun yarn offers superior strength and durability due to its polyester or nylon core wrapped with cotton or other natural fibers, making it ideal for high-performance textiles. Its elasticity enhances fabric recovery, reducing wear and tear, while also providing better comfort and breathability compared to traditional blended yarn. You benefit from improved fabric resilience and longevity, which extends the lifespan of garments and reduces replacement costs.

Benefits of Blended Yarn

Blended yarn offers enhanced durability and improved fabric performance by combining fibers with complementary properties such as cotton and polyester, delivering better strength, moisture-wicking, and wrinkle resistance. It provides cost efficiency by utilizing synthetic fibers alongside natural ones, reducing production expenses while maintaining quality and comfort. The versatility of blended yarn supports diverse textile applications, from apparel to home textiles, ensuring superior texture, color retention, and longer fabric lifespan compared to core spun yarn.

Applications and End-Uses comparison

Core spun yarn offers superior strength and elasticity, making it ideal for activewear, denim, and technical textiles where durability and stretch are essential. Blended yarn combines fibers like cotton and polyester for balanced comfort, breathability, and wrinkle resistance, commonly used in casual apparel, home textiles, and upholstery. You can choose core spun yarn for performance-driven products and blended yarn for versatile, everyday fabric applications.

Performance and Durability Analysis

Core spun yarn offers superior performance and durability due to its unique construction, combining a strong synthetic core with natural fibers that enhance tensile strength and elasticity. Blended yarns, while versatile, often exhibit varied durability depending on fiber proportions, where natural blends provide comfort but may lack the resilience of core spun yarns. In high-stress applications, core spun yarns maintain structural integrity longer, making them ideal for textiles requiring enhanced wear resistance and longevity.

Choosing Between Core Spun and Blended Yarn

Choosing between core spun and blended yarn depends on your project's durability and stretch requirements; core spun yarn features a strong synthetic core wrapped with natural fibers, offering enhanced elasticity and strength. Blended yarn combines different fibers uniformly, balancing the properties of each to achieve softness, moisture-wicking, or warmth. Understanding your fabric's intended use helps determine whether the robust structure of core spun or the versatile characteristics of blended yarn best suit your needs.

Core spun yarn vs Blended yarn Infographic

libmatt.com

libmatt.com