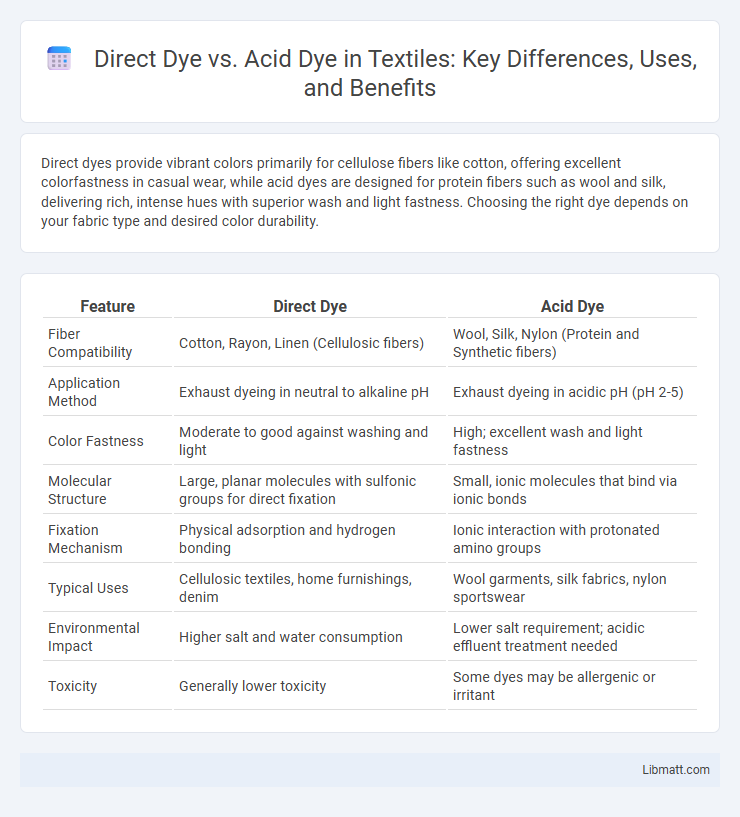

Direct dyes provide vibrant colors primarily for cellulose fibers like cotton, offering excellent colorfastness in casual wear, while acid dyes are designed for protein fibers such as wool and silk, delivering rich, intense hues with superior wash and light fastness. Choosing the right dye depends on your fabric type and desired color durability.

Table of Comparison

| Feature | Direct Dye | Acid Dye |

|---|---|---|

| Fiber Compatibility | Cotton, Rayon, Linen (Cellulosic fibers) | Wool, Silk, Nylon (Protein and Synthetic fibers) |

| Application Method | Exhaust dyeing in neutral to alkaline pH | Exhaust dyeing in acidic pH (pH 2-5) |

| Color Fastness | Moderate to good against washing and light | High; excellent wash and light fastness |

| Molecular Structure | Large, planar molecules with sulfonic groups for direct fixation | Small, ionic molecules that bind via ionic bonds |

| Fixation Mechanism | Physical adsorption and hydrogen bonding | Ionic interaction with protonated amino groups |

| Typical Uses | Cellulosic textiles, home furnishings, denim | Wool garments, silk fabrics, nylon sportswear |

| Environmental Impact | Higher salt and water consumption | Lower salt requirement; acidic effluent treatment needed |

| Toxicity | Generally lower toxicity | Some dyes may be allergenic or irritant |

Introduction to Direct Dye and Acid Dye

Direct dyes are water-soluble colorants primarily used for dyeing cellulosic fibers like cotton, providing bright, level colors through adsorption and hydrogen bonding. Acid dyes, characterized by their anionic nature, are mainly applied to protein fibers such as wool and silk under acidic conditions, forming ionic bonds with fiber amino groups for vibrant, wash-fast hues. Both dye types differ in chemical structure and application methods, influencing their affinity and suitability for various textile materials.

Chemical Structure and Properties

Direct dyes possess a linear, azo-based chemical structure that allows them to form strong hydrogen bonds with cellulose fibers, resulting in good affinity and moderate wash fastness on cotton. Acid dyes feature sulfonic acid groups attached to their aromatic rings, providing high water solubility and the ability to form ionic bonds with positively charged amino groups in protein fibers like wool and silk. The structural differences dictate their dyeing mechanisms: direct dyes rely on Van der Waals forces and hydrogen bonding while acid dyes depend on ionic interactions, influencing their respective fastness properties and application methods.

Suitable Fibers for Each Dye

Direct dyes are ideal for cellulose fibers such as cotton, rayon, and linen, offering vibrant colors and good colorfastness on these natural fibers. Acid dyes are best suited for protein fibers like wool, silk, and nylon, providing excellent brightness and washfastness on these materials. Choosing the appropriate dye based on your fiber type ensures optimal color performance and durability.

Dyeing Process Comparison

Direct dyes bind to fibers through hydrogen bonding and van der Waals forces, making them ideal for cellulose fibers like cotton and requiring a neutral or slightly alkaline dye bath. Acid dyes, however, form ionic bonds with protein fibers such as wool and silk, needing an acidic dye bath for effective fixation. Your choice between these dyes depends on the fiber type and desired colorfastness, with direct dyes offering simplicity and acid dyes providing superior brightness and wash durability.

Color Range and Brightness

Direct dyes offer a wide color range with vibrant and rich hues, especially suited for cellulose fibers like cotton. Acid dyes provide exceptionally bright and intense colors, particularly effective for protein fibers such as wool and silk. The brightness of acid dyes generally surpasses that of direct dyes due to their strong affinity and fixation on fibers in acidic conditions.

Fastness Properties: Light, Wash, and Rub

Direct dyes typically exhibit moderate wash fastness but lower light and rub fastness, making them more suitable for cellulose fibers like cotton where moderate durability is acceptable. Acid dyes demonstrate superior wash, light, and rub fastness due to their strong ionic bonding with protein fibers such as wool and silk, resulting in vibrant and long-lasting colors. The choice between direct and acid dyes largely depends on the required durability and fabric type, with acid dyes preferred when enhanced fastness properties are critical.

Environmental Impact and Safety

Direct dyes typically have a lower environmental impact due to their simpler application process, which requires less energy and fewer chemicals compared to acid dyes. Acid dyes often involve acidic conditions and heavy metal mordants that pose higher risks to aquatic life and can generate hazardous waste. Choosing direct dyes for your textile projects can reduce harmful chemical discharge and improve workplace safety by minimizing exposure to toxic substances.

Cost and Availability

Direct dyes are generally more cost-effective and widely available due to their simpler production processes and common use in cellulose fibers like cotton. Acid dyes tend to be more expensive because of their specialized application for protein fibers such as wool and silk, requiring more complex chemical formulations. Availability of acid dyes is more limited and often restricted to specialty suppliers compared to the broader market presence of direct dyes.

Typical Applications in Industry

Direct dyes are predominantly used in the textile industry for dyeing cotton, rayon, and other cellulosic fibers, offering vibrant colors ideal for fabrics and garments. Acid dyes find extensive application in dyeing protein fibers such as wool, silk, and nylon, commonly utilized in upholstery, leather, and carpet manufacturing. Both dye types are essential in producing diverse colored products tailored to specific fiber properties and industrial requirements.

Choosing the Right Dye: Key Considerations

Selecting the right dye involves evaluating fabric type, dye compatibility, and desired colorfastness. Direct dyes are ideal for cellulose fibers like cotton, offering ease of application and bright shades, whereas acid dyes are suited for protein fibers such as wool and silk, providing vibrant colors with strong fiber bond and washfastness. Consider factors like water temperature, fixation methods, and end-use durability to ensure optimal dye performance and longevity.

Direct Dye vs Acid Dye Infographic

libmatt.com

libmatt.com