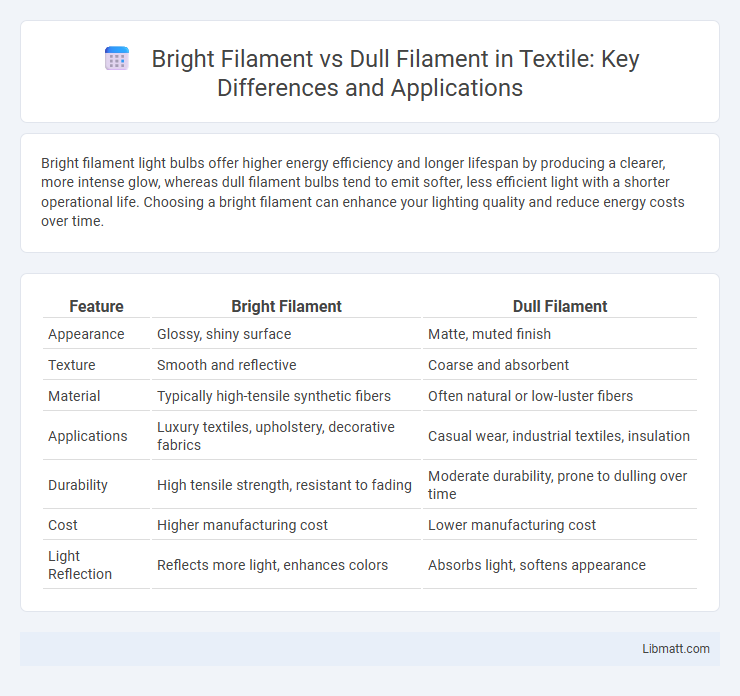

Bright filament light bulbs offer higher energy efficiency and longer lifespan by producing a clearer, more intense glow, whereas dull filament bulbs tend to emit softer, less efficient light with a shorter operational life. Choosing a bright filament can enhance your lighting quality and reduce energy costs over time.

Table of Comparison

| Feature | Bright Filament | Dull Filament |

|---|---|---|

| Appearance | Glossy, shiny surface | Matte, muted finish |

| Texture | Smooth and reflective | Coarse and absorbent |

| Material | Typically high-tensile synthetic fibers | Often natural or low-luster fibers |

| Applications | Luxury textiles, upholstery, decorative fabrics | Casual wear, industrial textiles, insulation |

| Durability | High tensile strength, resistant to fading | Moderate durability, prone to dulling over time |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Light Reflection | Reflects more light, enhances colors | Absorbs light, softens appearance |

Understanding Filament Brightness: An Overview

Filament brightness in lighting technology is determined by the material composition and temperature of the filament, with bright filaments typically made from tungsten that glows intensely at high temperatures. Dull filaments exhibit lower luminosity due to surface oxidation or impurities that reduce their efficiency in emitting visible light. Understanding the differences in filament brightness is crucial for selecting appropriate bulbs for energy efficiency, light output, and application-specific needs.

Defining Bright Filament and Dull Filament

Bright filament refers to a lighting filament that produces a strong, vivid, and luminous glow, commonly used in applications requiring high visibility and clarity. Dull filament, in contrast, emits a softer, more subdued light with lower intensity and brightness, suitable for ambient or decorative lighting purposes. Understanding these differences helps you select the appropriate filament type based on the desired brightness and visual effect for your lighting needs.

Materials Used in Bright and Dull Filaments

Bright filaments are typically made from pure tungsten or tungsten alloys with minimal impurities, resulting in a smooth, reflective surface that enhances brightness in light bulbs. Dull filaments contain additives such as thorium or potassium compounds, which create a rougher surface to reduce glare and produce a softer light. Understanding the materials used in your filaments helps optimize lighting performance for specific applications.

Electrical Properties of Bright vs. Dull Filament

Bright filaments exhibit higher electrical conductivity due to their smoother surface and purer tungsten composition, resulting in lower resistance and improved efficiency in electrical current flow. Dull filaments often have a rougher surface with impurities that increase resistance and cause higher energy loss through heat. Understanding these differences helps you optimize filament selection for applications requiring stable electrical performance and energy efficiency.

Light Output and Luminance Differences

Bright filaments emit higher light output due to their increased surface temperature, resulting in intensified luminance and improved visibility. In contrast, dull filaments produce lower light output with reduced luminance, leading to softer illumination and less brightness. The material composition and filament thickness directly influence these differences, impacting both energy efficiency and light quality.

Energy Efficiency Comparison

Bright filaments in incandescent bulbs convert a higher percentage of electrical energy into visible light, resulting in better energy efficiency compared to dull filaments, which emit more heat and waste energy. The higher luminous efficacy of bright filaments means your lighting consumes less power for the same brightness level, lowering energy costs. Selecting bulbs with bright filament technology helps enhance overall energy savings and reduces your carbon footprint.

Applications of Bright Filament

Bright filament wires, primarily made of bright-drawn steel, are ideal for applications requiring high tensile strength and smooth surface finish such as springs, fasteners, and wire forms. Your manufacturing processes benefit from bright filaments' superior ductility and corrosion resistance, making them suitable for precise and aesthetically critical components. These filaments are essential in automotive, construction, and electronics industries where reliable performance and appearance are crucial.

Applications of Dull Filament

Dull filaments are widely used in applications requiring consistent and stable electron emission, such as in industrial vacuum tubes, electron microscopes, and cathode ray tubes. Their lower brightness compared to bright filaments results in longer lifespan and reduced thermal stress, making them ideal for prolonged operation in sensor devices and vacuum gauges. Industries relying on precise electron beam control favor dull filaments for durability and reliable performance.

Lifespan and Durability Factors

Bright filaments typically have a shorter lifespan due to their higher operating temperatures, which causes faster material evaporation and degradation. Dull filaments operate at lower temperatures, enhancing durability and extending the bulb's overall lifespan by reducing thermal stress. Your choice between bright and dull filaments should balance desired brightness with the need for longer-lasting performance.

Choosing Between Bright and Dull Filament

Choosing between bright and dull filament depends on the desired lighting effect and application. Bright filament offers higher luminosity and a vibrant glow, ideal for decorative lighting that requires strong visual impact. Dull filament provides softer, more diffused light suitable for ambient or mood lighting, emphasizing subtle warmth over intensity.

Bright filament vs Dull filament Infographic

libmatt.com

libmatt.com