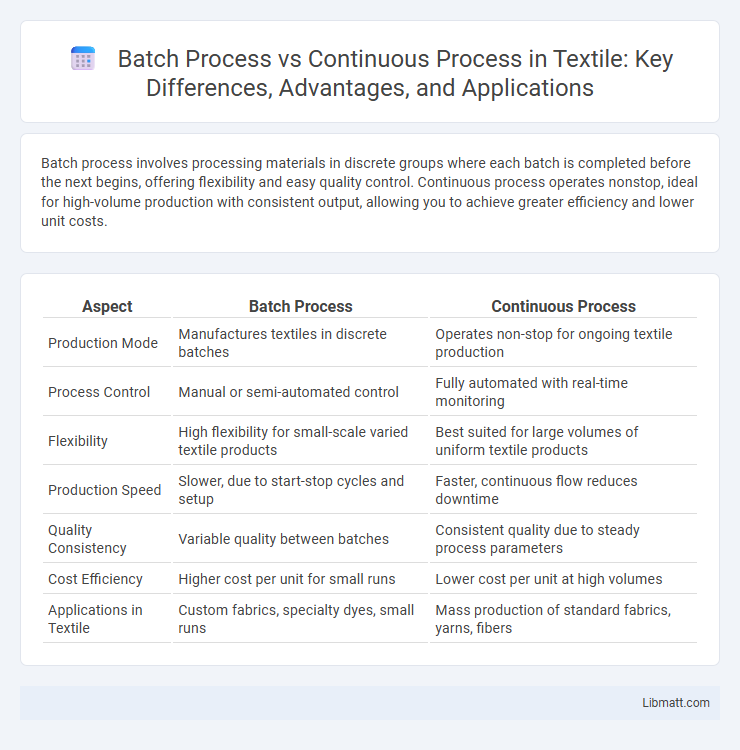

Batch process involves processing materials in discrete groups where each batch is completed before the next begins, offering flexibility and easy quality control. Continuous process operates nonstop, ideal for high-volume production with consistent output, allowing you to achieve greater efficiency and lower unit costs.

Table of Comparison

| Aspect | Batch Process | Continuous Process |

|---|---|---|

| Production Mode | Manufactures textiles in discrete batches | Operates non-stop for ongoing textile production |

| Process Control | Manual or semi-automated control | Fully automated with real-time monitoring |

| Flexibility | High flexibility for small-scale varied textile products | Best suited for large volumes of uniform textile products |

| Production Speed | Slower, due to start-stop cycles and setup | Faster, continuous flow reduces downtime |

| Quality Consistency | Variable quality between batches | Consistent quality due to steady process parameters |

| Cost Efficiency | Higher cost per unit for small runs | Lower cost per unit at high volumes |

| Applications in Textile | Custom fabrics, specialty dyes, small runs | Mass production of standard fabrics, yarns, fibers |

Introduction to Batch and Continuous Processes

Batch processes involve producing products in discrete groups or quantities, allowing flexibility in manufacturing diverse or customized goods. Continuous processes operate non-stop, maintaining a steady flow of materials and production, ideal for large-scale, consistent manufacturing such as chemicals, oil refining, and food processing. Each process type offers unique advantages in efficiency and scalability depending on production goals and product nature.

Defining Batch Process

A batch process involves producing products in specific, separate quantities or lots, where each batch undergoes a distinct sequence of operations before the next batch begins. This method allows for greater flexibility in manufacturing different products and easier quality control within each batch. Your production can benefit from this approach when handling customized orders or varying product lines requiring discrete processing steps.

Defining Continuous Process

Continuous process defines a manufacturing method where raw materials are constantly fed into the system, and products are simultaneously produced without interruption. It enables consistent quality, higher throughput, and reduced labor costs by maintaining an ongoing flow of production. Industries such as chemicals, oil refining, and food processing widely use continuous processes to optimize efficiency and scalability.

Key Differences Between Batch and Continuous Processing

Batch processing involves handling discrete quantities of materials in separate, sequential steps, making it ideal for smaller production runs or varying products. Continuous processing maintains a constant flow of material through the production system, optimizing efficiency for large-scale, uniform output with minimal downtime. Key differences include production scale, operational complexity, and flexibility, with batch processing offering customization and continuous processing favoring consistency and speed.

Advantages of Batch Processing

Batch processing allows for greater flexibility in handling varied product types and smaller production runs, making it ideal for customized orders and seasonal demand. It enhances quality control by enabling thorough inspection between batches, reducing the risk of defects and waste. Your operations benefit from easier maintenance and setup changes, minimizing downtime and improving overall efficiency.

Advantages of Continuous Processing

Continuous processing offers increased efficiency by allowing uninterrupted production, reducing downtime, and improving throughput rates compared to batch processing. It enhances product consistency and quality through steady-state operation and real-time monitoring, minimizing variability. Additionally, continuous processing reduces operational costs by maximizing equipment utilization and lowering labor requirements.

Limitations of Batch Processing

Batch processing faces limitations such as longer production cycles and higher downtime due to equipment cleaning and setup between batches. It often results in inconsistent product quality compared to continuous processing, which maintains steady operation. Your manufacturing efficiency can be affected by the reduced flexibility and slower response to demand changes typical of batch processes.

Limitations of Continuous Processing

Continuous processing faces limitations such as high initial capital investment and complex maintenance requirements, which can pose challenges for smaller-scale operations. Flexibility is reduced compared to batch processes, making it difficult to accommodate product variations or frequent changes in production. Your manufacturing system may also experience issues with process control and quality consistency if raw material variations are significant in continuous operations.

Industry Applications and Use Cases

Batch processes are commonly used in pharmaceutical manufacturing, specialty chemicals, and food production where precise formulation and flexibility are critical. Continuous processes are favored in industries like oil refining, petrochemicals, and large-scale chemical production due to their efficiency and consistent output. Your choice depends on production volume, product complexity, and the need for quality control in specific industry applications.

Choosing the Right Process for Your Needs

Choosing between batch and continuous processes depends on your production volume, product complexity, and operational flexibility requirements. Batch processing suits small-scale, customizable production with frequent changes, while continuous processing excels in large-scale, consistent output with minimal downtime. Evaluating your specific manufacturing goals ensures optimal efficiency and cost-effectiveness in your production strategy.

Batch process vs Continuous process Infographic

libmatt.com

libmatt.com