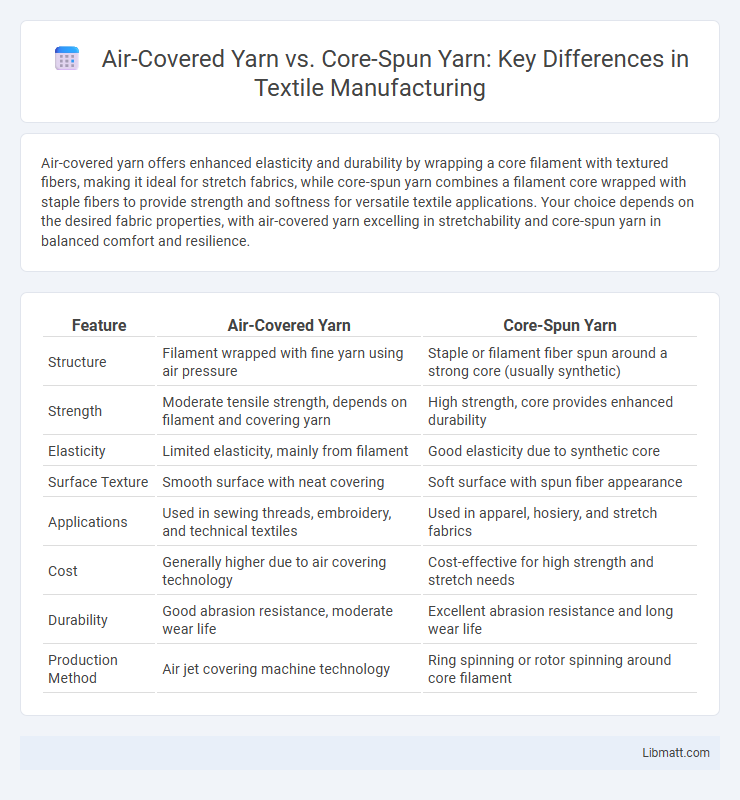

Air-covered yarn offers enhanced elasticity and durability by wrapping a core filament with textured fibers, making it ideal for stretch fabrics, while core-spun yarn combines a filament core wrapped with staple fibers to provide strength and softness for versatile textile applications. Your choice depends on the desired fabric properties, with air-covered yarn excelling in stretchability and core-spun yarn in balanced comfort and resilience.

Table of Comparison

| Feature | Air-Covered Yarn | Core-Spun Yarn |

|---|---|---|

| Structure | Filament wrapped with fine yarn using air pressure | Staple or filament fiber spun around a strong core (usually synthetic) |

| Strength | Moderate tensile strength, depends on filament and covering yarn | High strength, core provides enhanced durability |

| Elasticity | Limited elasticity, mainly from filament | Good elasticity due to synthetic core |

| Surface Texture | Smooth surface with neat covering | Soft surface with spun fiber appearance |

| Applications | Used in sewing threads, embroidery, and technical textiles | Used in apparel, hosiery, and stretch fabrics |

| Cost | Generally higher due to air covering technology | Cost-effective for high strength and stretch needs |

| Durability | Good abrasion resistance, moderate wear life | Excellent abrasion resistance and long wear life |

| Production Method | Air jet covering machine technology | Ring spinning or rotor spinning around core filament |

Introduction to Air-Covered Yarn and Core-Spun Yarn

Air-covered yarn features a core filament wrapped tightly with an outer layer of spun fibers using high-velocity air jets, enhancing strength and elasticity while maintaining a soft texture. Core-spun yarn consists of a central filament wrapped with staple fibers through a conventional spinning process, providing durability and improved fabric appearance. Both yarn types combine the advantages of filament strength and staple fiber comfort to meet specific textile performance requirements.

Manufacturing Processes: Air-Covered vs Core-Spun Yarns

Air-covered yarn manufacturing involves wrapping an elastic filament, such as spandex, with a high-speed air-jet wrapping of fine polyester or nylon filaments, creating a smooth, lightweight, and stretchable yarn. In contrast, core-spun yarn production entails spinning staple fibers, like cotton or wool, directly around an elastic filament core, resulting in a yarn with enhanced strength and a natural fiber surface. The air-jet wrapping process offers superior uniformity and elasticity, while core-spun yarns provide greater comfort and durability due to their fibrous sheath.

Raw Materials Used in Each Yarn Type

Air-covered yarn primarily consists of a central filament, often polyester or nylon, wrapped with fine fibers such as cotton or wool using air-jet technology. Core-spun yarn features a strong filament core, typically polyester or spandex, encased with staple fibers like cotton or rayon to enhance flexibility and comfort. Understanding the raw materials used in each yarn type helps you choose the best option for durability, stretch, and fabric texture in your textile projects.

Structural Differences Between Air-Covered and Core-Spun Yarns

Air-covered yarn features a core filament wrapped with a high-twist filament spun using air jets, resulting in a lightweight and smooth surface with improved elasticity. Core-spun yarn consists of a central core fiber wrapped tightly by staple fibers through ring spinning, providing enhanced strength and softness due to the core's continuous filament and the outer fiber's fineness. These structural variations influence yarn performance, with air-covered yarn favoring elasticity and surface uniformity, while core-spun yarn excels in durability and comfort.

Physical and Mechanical Properties Comparison

Air-covered yarn exhibits superior elasticity and softness due to its filament-wrapped staple fibers, enhancing fabric comfort and stretch recovery. Core-spun yarn features a strong, continuous filament core wrapped with staple fibers, resulting in higher tensile strength and abrasion resistance ideal for durable textiles. Both yarns balance flexibility and strength, but air-covered yarn prioritizes softness while core-spun yarn emphasizes mechanical robustness.

Key Applications in Textile Industries

Air-covered yarn is primarily used in high-performance textiles such as sportswear and automotive upholstery due to its enhanced strength, elasticity, and abrasion resistance. Core-spun yarn finds extensive application in denim fabrics, hosiery, and technical textiles where a blend of comfort and durability is essential. Both yarn types contribute significantly to innovations in protective clothing, industrial fabrics, and fashion textiles, optimizing fabric performance based on specific industry requirements.

Advantages and Limitations: Air-Covered Yarn

Air-covered yarn offers enhanced elasticity and smoothness, making it ideal for applications requiring stretch and softness, such as hosiery and underwear. Its production process results in better yarn coverage and improved abrasion resistance, contributing to garment durability. However, air-covered yarn may have limitations in strength compared to core-spun yarn and can be more costly due to specialized machinery and processing time.

Pros and Cons: Core-Spun Yarn

Core-spun yarn combines a strong filament core with a softer fiber sheath, offering enhanced strength and durability compared to traditional yarns. Its key advantages include improved tensile strength, better elasticity, and resistance to abrasion, making it ideal for applications requiring high performance and comfort. However, core-spun yarn can be more expensive to produce and may have limited breathability compared to air-covered yarn, impacting its suitability for certain textile products.

Cost Efficiency and Production Considerations

Air-covered yarn offers higher cost efficiency by reducing raw material usage and enabling faster production speeds, which lowers overall manufacturing expenses compared to core-spun yarn. Core-spun yarn requires more complex machinery and longer processing times, increasing production costs and limiting throughput. Manufacturers prioritize air-covered yarn for large-scale, cost-effective textile production, while core-spun yarn is chosen for specialized applications requiring enhanced yarn strength and durability despite higher costs.

Choosing the Right Yarn: Factors to Consider

Choosing the right yarn depends on the intended fabric performance and end-use requirements, where air-covered yarn offers lightweight, breathable properties ideal for sportswear and activewear, while core-spun yarn provides enhanced strength and durability suited for heavy-duty applications. Your decision should factor in yarn elasticity, abrasion resistance, and comfort level to ensure optimal garment functionality. Consider production costs and sustainability aspects when selecting between air-covered and core-spun yarns to align with your manufacturing goals.

Air-covered yarn vs Core-spun yarn Infographic

libmatt.com

libmatt.com